Despite the large selection of energy sources, firewood in some cases remains the most relevant type of fuel. They have good heat dissipation, affordable cost and do not emit harmful chemicals. In order to heat a private house with wood, boilers, stoves and other components are needed.

Advantages and disadvantages of wood heating

One of the defining advantages that wood-fired water heating has is complete independence from electricity. For normal operation of the heat supply, an electrical connection is not required. The control over the parameters of the system is carried out by means of mechanical components.

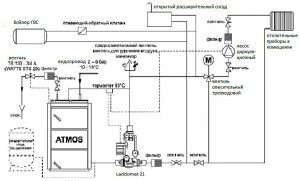

For the correct organization, you need to draw up the correct scheme. It should include not only the elements for maintaining a comfortable temperature level (batteries, radiators, pipes), but also the characteristics of the heating boiler. If you plan to use wood-fired air heating or its water-based counterpart, you should purchase modern equipment.

This type of fuel, with a classic combustion scheme, quickly gives off heat. Therefore, it is necessary to use all the factors that increase the heat transfer of one firewood bookmark. For this, long-burning pyrolysis boilers are purchased.

If the above condition is met, then heating a country house with wood will have the following positive qualities:

- Minimum fuel purchase costs... But this may be relevant only in those regions where the supply of firewood is well organized;

- Affordable equipment cost... An exception is wood-fired heating in a private house using long-burning boilers;

- No need to apply for a permit for the installation of heat supply of this type.

The disadvantage is the need to have a large supply of fuel. Since its properties directly depend on environmental conditions, a certain temperature and humidity should be observed for storage. In this case, the boiler for heating a private house on wood should not be in the same room with the fuel.

Since a large amount of soot is released during combustion, the chimney must be cleaned once every 2 years. Otherwise, its bore diameter will decrease, and the traction indicators will decrease.

Wood stoves

Initially, wood-burning stoves were used. These are large structures made of special refractory bricks. To increase heat transfer, the chimney system must have complex channels. Hot air passing through them warmed up the inner walls of the house. For small buildings, there was no need to install piping and radiators. A properly made wood-fired air heating stove could provide a comfortable temperature level.

When choosing this type of heat supply, it is necessary to correctly draw up a laying scheme. It is best to use standard projects for this. They guarantee the correct operation of the structure, a high level of heat transfer. Also an important advantage is the ability to manufacture wood-fired water heating stoves. A heat exchanger is installed in the combustion chamber during installation. In the future, it will be connected to the general heat supply system.

In this case, you can independently choose its volume, design and material of manufacture.The last factor needs to be given special attention, since wood-fired steam heating is characterized by high temperatures. Refractory steel grades with wall thicknesses of 1.5 mm or more have proven themselves best.

There are several options for how you can make heating a private house with wood with your own hands:

- Furnace with firebox without additional functions... It is a simple structure consisting of a combustion chamber, ash pan and chimney. It is characterized by its small size, it is equipped for summer cottages and country houses with a small area;

- Stove with oven and hob... Has a more complex configuration than the above model. In addition to the combustion chamber, ash pan and chimney, the structure contains an oven and a hob that have direct contact with the firebox.

For the latter option, it is important to choose the right masonry scheme. Step-by-step instructions will allow you to complete the entire scope of work yourself, without the involvement of specialists.

During the arrangement of air heating, a separate foundation is made on wood. This is due to the large mass of the structure.

Its upper plane should be 5-7 cm below the level of the clean floor. The dimensions of the foundation should be 5-6 cm larger than the dimensions of the furnace for heating a house on wood.

The furnace is made of special fireclay refractory bricks. Often, the temperature in the combustion chamber of a wood-fired air heating stove reaches + 500 ° C. This material is designed to withstand such thermal effects.

Characteristics of wood-fired boilers

The best characteristics are the wood-fired steam heating boiler. Its overall dimensions are much smaller than that of a furnace, and their capacities are comparable. Installation does not require much effort. Instead of laborious laying of wood-fired air heating stoves, it is enough to correctly position the boiler and connect it to the heat supply.

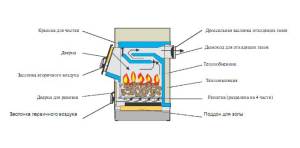

The classic scheme of a boiler for heating a private house on wood includes a combustion chamber, an ash collector and a chimney. Those. this is no different from the oven. It is much more practical to use steam heating boilers on long burning wood.

Their principle of operation is to release the bulk of thermal energy not due to the combustion of solid fuel, but wood gas. It is released in the process of smoldering and enters the afterburner. This is where air is pumped and the gas is ignited. For such water heating on wood, a high efficiency is characteristic.

In addition to this factor, the following features can be distinguished, which are characteristic only for heating with wood in a private house using long-burning boilers:

- Long operating time with one fuel fill... If the operating conditions are observed, the boiler will be able to operate in the optimal mode from 6 to 10 hours on one batch of fuel;

- Low temperature operating mode... When organizing heating a country house with wood with a pyrolysis boiler, most often the maximum water temperature is + 65 ° C. This is due to the relatively low heat transfer. Therefore, it is necessary to take care of good insulation at home;

- Chimney system... Since the temperature of carbon monoxide gases is relatively low, the pipe will not warm up well enough. Therefore, do-it-yourself wood-fired heating is completed with an insulated chimney. Otherwise, condensate will enter the boiler.

If it is necessary to organize heat supply for a small house, then a small structure with a hob may be the best option. It does not need to have a heat exchanger. A homemade wood-fired heating boiler is made according to pre-drawn drawings.

When choosing factory models, you need to pay attention to the material of manufacture. Most often, wood-fired boilers for heating a private house are made of heat-resistant steel.For intensive use, it is recommended to purchase models with a cast iron heat exchanger.

For the correct choice of a boiler for steam heating on wood, the following factors must be taken into account:

- Equipment rated power... Calculated in advance, based on the heat loss of the house, its area and volume;

- Total weight of the structure... The floor in the boiler room must support the weight taking into account the fuel load and the filled heat exchanger;

- Operation control device... For the correct organization of heating a country house using firewood, pressure and temperature sensors must be installed in the boiler structure. For automatic regulation of the intensity of combustion, some models provide a mechanism for opening / closing the ash pan door. It controls the volume of air flow to maintain the combustion process.

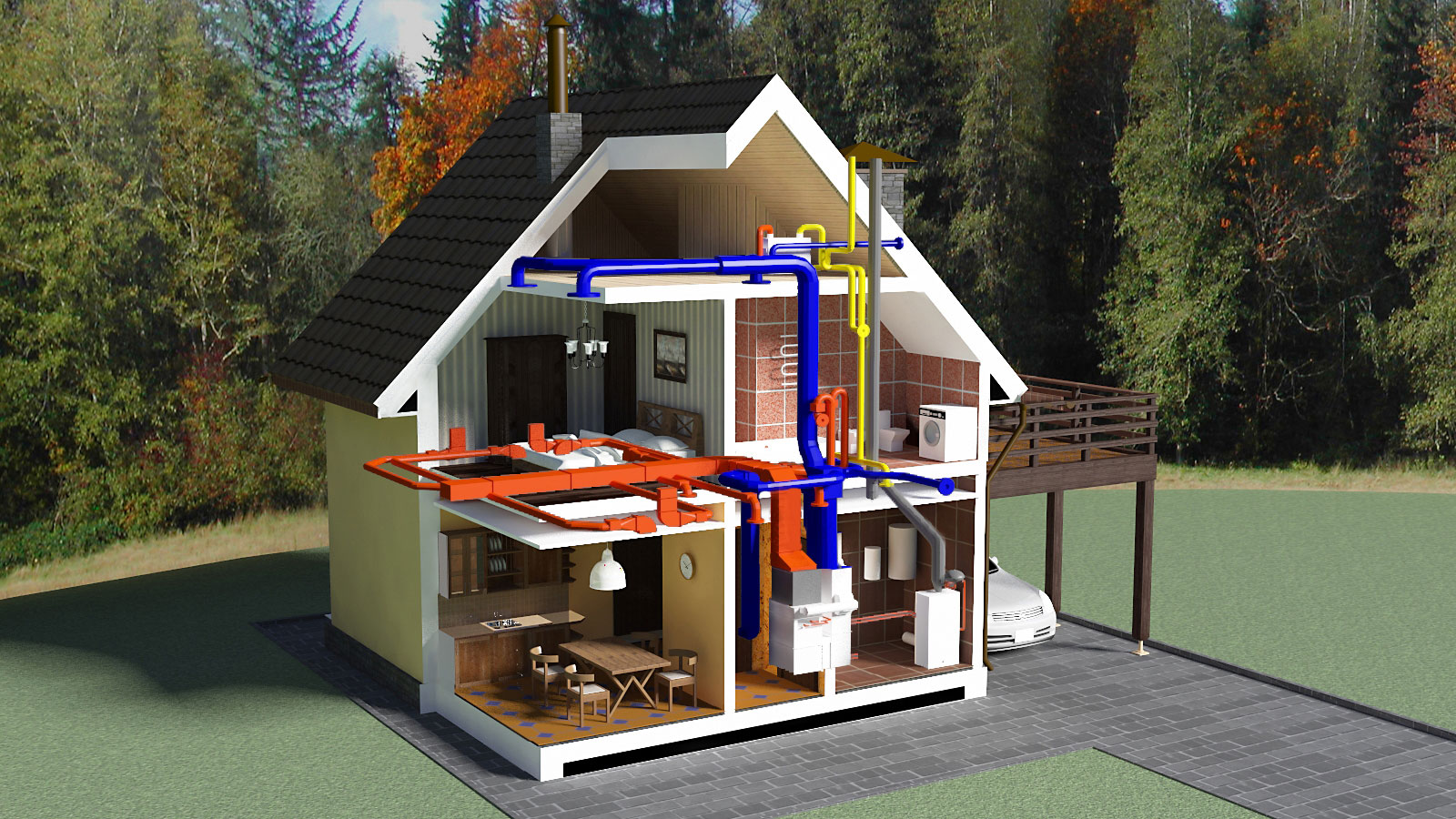

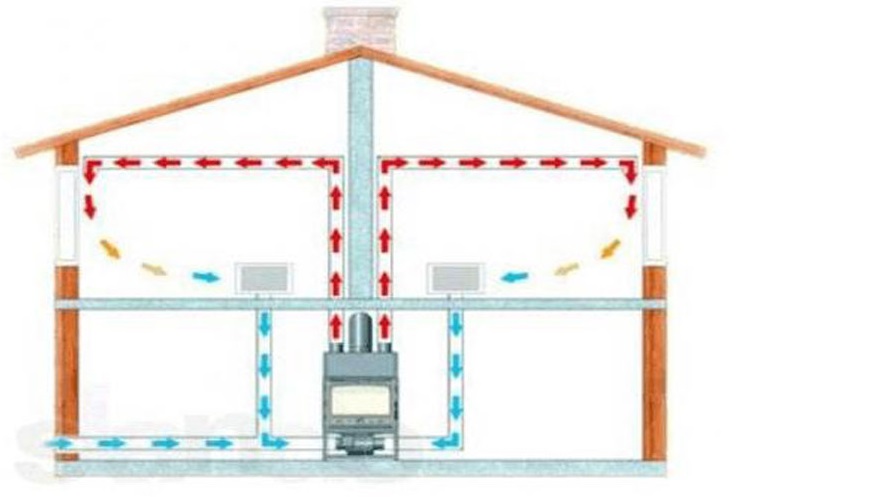

You can make air heating on wood. There are 2 ways to organize such heating. The first is to purchase a boiler with air tubes. It is designed to maintain a comfortable temperature in a small room. The second option is more time consuming. An air chamber is installed on top of a boiler or stove to heat a country house with firewood. It is connected to piping systems through which hot air enters the rooms of the house.

Firewood should be stored in a separate room. Their importance cannot exceed 8%. Otherwise, the heat transfer performance will deteriorate.

Rules for installing wood heating

Do-it-yourself installation of wood-fired heating is carried out according to a previously drawn up scheme. The plan of the house is used as a source, which marks the location of the boiler, pipes and radiators. In addition to them, air vents, drain valves and an expansion tank must be installed in the water heating system.

It is important to follow all safety rules. They differ depending on what equipment is used to heat a private house with wood with your own hands. Stoves are installed in living rooms.

Therefore, there must be a good level of ventilation. During the operation of steam heating on wood, a small part of carbon monoxide gases may enter the room. Ventilation is necessary for their timely removal.

For water heating on wood with the help of a boiler, a separate room is equipped. The boiler room can be located both in the house and in the annex. The basic requirements for this type of wood-fired heat supply in a private house are as follows:

- Compulsory natural lighting along with artificial;

- Use of non-combustible materials in the boiler area;

- The minimum chimney height must be 3.5 m;

- If a homemade wood-fired heating boiler is used, exhaust ducts are additionally mounted. Unlike factory models, a home-made design cannot provide a good degree of reattachment of the door to the firebox. This can cause high concentrations of carbon monoxide.

For steam heating on wood, it is important to choose the right location for the stove or boiler. Warm air currents should circulate throughout the entire home. For the furnace, a coarse is equipped, which contributes to a better heat distribution.

If you plan to install an air boiler of the Buderus type, you need to make a base for it with a height of 10 to 30 cm. You can do this type of heat supply for a private house with firewood with your own hands. You just need to follow the above recommendations.

To accumulate thermal energy, the surface of the wood-fired air heating furnace is faced with silicate bricks or ceramic tiles. They concentrate heat, prevent the outer walls from heating up to high temperatures.

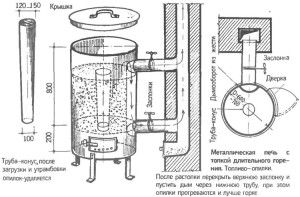

Homemade wood burning boiler

For heating a small office or utility room, you can make a homemade boiler with your own hands.Most often this is important for organizing heat supply to a garage, a small production workshop or warehouse. The manufacture of wood-burning stoves is done with the help of scrap materials.

A steel barrel is used as a frame, the wall thickness of which should not be less than 1 mm. Additionally, you will need round pipes, doors for the blower and combustion chambers.

To assemble the structure, you will need a welding machine, a grinder with a disc for metal, and a measuring tool. Previously, paint is removed from the surface of the workpieces. Why markup is applied to them. Parts are manufactured according to the drawing.

During the installation of heat supply on wood with your own hands, the following nuances are taken into account:

- The firebox and ash pan must be airtight;

- The chimney diameter is 50 mm;

- The light weight of the structure makes it possible to install it on legs. This will reduce heat losses and increase operational safety.

Particular attention is paid to the quality of the welded seams. You must first select the correct brand of electrodes.

In the video, you can get acquainted with the detailed instructions for the manufacture of a wood-fired pyrolysis boiler:

And someone else drowns with wood? You pass gas or a bottle and you're done. Why all this hemorrhoids?

Now there are many solutions, this is true, but it all depends on the territorial location of the house. Gas is not installed everywhere and it is not always possible to buy it profitably. Therefore, it will not be superfluous to know about such an alternative as firewood (and now the efficiency of such stoves is much higher than before).