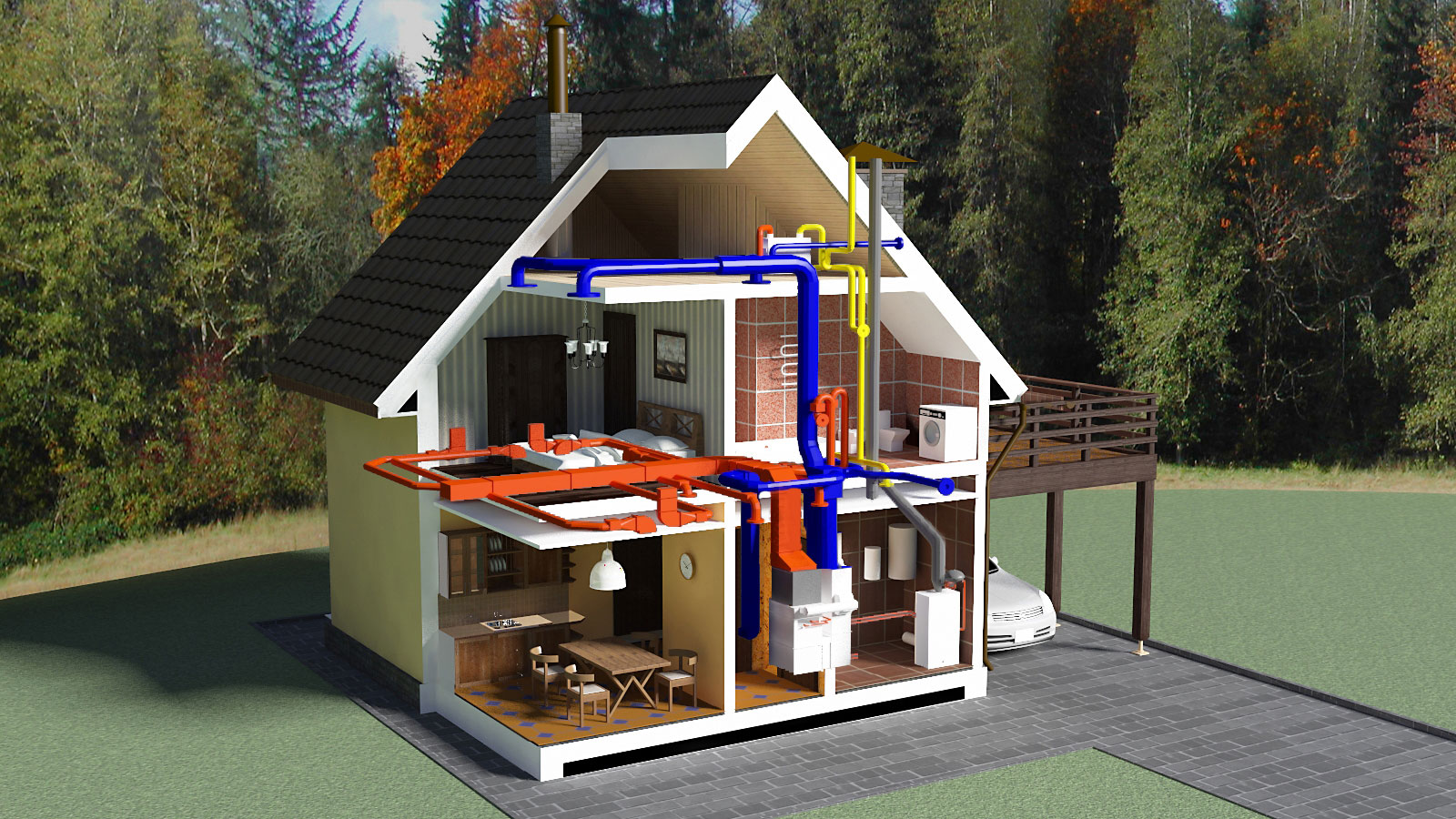

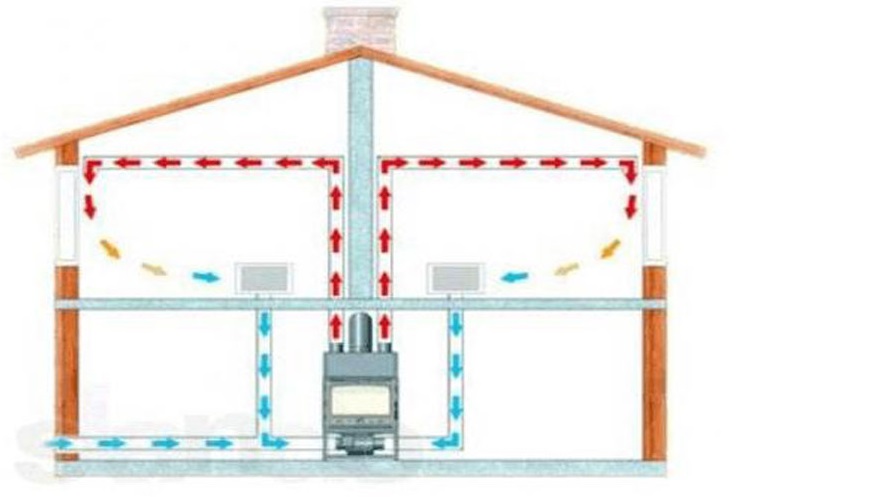

Piping in the heating system of a house or apartment plays a key role. With their help, the coolant is transported, and uniform heat distribution is ensured. Along with steel mains, heating of a private house with plastic pipes and radiators is increasingly common.

Features of the use of plastic pipes in heating

In order to make plastic heating with your own hands, you first need to find out all the nuances of using this type of pipes. They are made of polymeric materials of various types, which ultimately determines their functional features.

High-quality plastic heating wiring has a number of advantages. These include ease of installation, affordable materials and the ability to manufacture complex systems. However, you need to take into account the technical characteristics of polymer products. Some of the pipe models are not suitable for use in heating systems. Therefore, before making plastic heating in a private house, you should choose the right pipes.

After professional installation, water heating from plastic pipes should have the following properties:

- Minimal heat loss... Polymers have the lowest heat transfer value. This minimizes the transfer of thermal energy from the coolant during its transportation to radiators and batteries;

- Critical system pressures... This indicator is decisive when choosing pipes. Many models are designed for a maximum pressure of up to 20 atm. However, the installation of plastic heating is carried out using soldering or mechanical fittings. Most often, breakdowns occur in these places;

- Maximum water temperature... Before choosing plastic pipes for heating, a preliminary calculation of the temperature regime of the system is carried out. Almost all models of polymer pipes are designed for maximum temperature exposure up to + 90 ° С;

- Thermal expansion... This is one of the properties of polymers. During operation, pipes and plastic heating radiators can increase their overall dimensions by 3-5%. Therefore, to prevent increased surface tension, special compensation units are installed.

For heat supply, reinforced plastic pipes for heating are used. Their construction is provided with a layer of another material (aluminum foil, fiberglass), which provide adequate rigidity.

With the possible formation of ice plugs, the plastic heating manifold and pipes may lose their tightness. To avoid such situations, it is necessary to insulate the pipelines or install a heating cable.

Types of plastic pipes for heating

Currently, manufacturers offer several types of plastic pipes for autonomous heating. The difference between them lies in the materials used, which ultimately determine their properties. Therefore, before making plastic heating with your own hands, it is imperative to familiarize yourself with the characteristics of the pipes.

The types of plastic pipes used for heating can be divided into three types - metal-plastic, polypropylene and cross-linked polyethylene products. Each of these types has unique performance properties. The choice is determined by the initial characteristics of heating - pressure, possible temperature drops, intensity of operation, etc. Therefore, for the manufacture of high-quality plastic heating in a private house, we will consider the most significant parameters:

- Operating temperature... Pipes made of cross-linked polyethylene have the least retention of rigidity - deformation begins already at + 80 ° C. Reinforced models of polypropylene products have a higher temperature threshold - up to + 90 ° C. The best performance is characterized by metal-plastic pipes - up to + 95 ° С;

- Connection reliability... A lower indicator of reliability is possessed by water heating made of metal-plastic pipes. Clamping connections are susceptible to depressurization during sudden pressure surges. XLPE pipes have the same negative properties. For autonomous or centralized plastic heating with your own hands, it is recommended to use polypropylene pipes, which are connected by soldering;

- Durability... If the operating standards are observed, the maintenance-free operation of the plastic heating wiring can be 20-25 years. However, this indicator directly depends on the characteristics of heating and many external factors.

Experts advise to choose plastic pipes for heating made of polypropylene. They have optimal cost, reliability and can be installed independently.

The defining indicators when choosing this type of pipelines are the diameter of the product and the type of reinforcement. To maintain the rigidity of the plastic shell when exposed to high temperatures, the following materials can be used in the manufacture of reinforced plastic pipes for heating:

- Foil aluminum... The disadvantage of this type of reinforcement is the likelihood of plastic delamination from the reinforcing layer. This happens if the pipe manufacturing technology is not followed;

- Fiberglass... A relatively new material that is characterized by a high degree of reliability. The only drawback of fiberglass-reinforced plastic heating pipes is the high cost.

Considering the large number of types of plastic pipes for heating, both by material of manufacture and by trademarks, when choosing, you need to pay attention to their appearance and marking. Knowing the latter will allow you to correctly determine the type of plastic pipes for a specific heating system.

For a water-heated floor system, it is best to use XLPE pipes. They have sufficient flexibility, which is a big "plus" when forming a warm surface. To install this type of plastic heating with your own hands, you should choose pipes with a protective layer that prevents oxygen from entering the coolant.

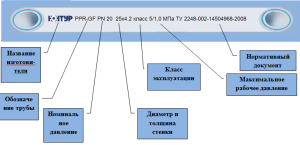

Marking of plastic pipes for heating

Heat supply from polypropylene plastic pipes should be done only after a detailed study of the marking. It will help you determine the maximum allowable pressure, class and compliance of the product with regulatory documents. It is also necessary when making a plastic heating manifold with your own hands.

High-quality soldering of plastic heating pipes is carried out only with products designed for exposure to high temperatures. For heat supply, you should choose PPR pipes that can withstand constant thermal exposure up to + 90 ° С and short-term - up to + 95 ° С. An important factor is the manufacturer. Information about this can also be found from the marking of plastic pipes for heating.Visually, polypropylene pipes for heating can be identified by the longitudinal red stripe. In some models, in addition to it, blue is also found, which indicates the possibility of using it in plumbing systems.

Before choosing and installing plastic heating, it is recommended that you familiarize yourself with the following data from the pipe marking:

- Operating pressure... This parameter is indicated after the letters "PN". For heating, plastic heating pipes PN20 and PN are welded. The latter option is highly reliable, therefore it is installed in centralized heating;

- Service class... You need to know for the maximum temperature in heating. For water heat supply from plastic pipes, products of class 4 and 5 are used. The first is designed for low-temperature systems (up to + 60 °), and pipes of the 5th class can withstand a maximum temperature of up to + 90 ° C;

- Pipe diameter... For plastic lines, the external indicator is indicated. Therefore, the manufacturer gives the wall thickness as additional information.

Knowing the wall thickness is necessary for the correct soldering of plastic heating pipes. The time of thermal effect on the material depends on this. For the correct manufacture of plastic heating with your own hands, it is recommended to study the regulatory documents, links to which can be found in the marking. Internal specifications do not always comply with general manufacturing standards.

The marking of plastic pipes for heat supply is applied along the product along its entire plane. Its absence indicates the low quality of the pipe. Therefore, you do not need to purchase such models.

Self-assembly of a plastic heating pipe

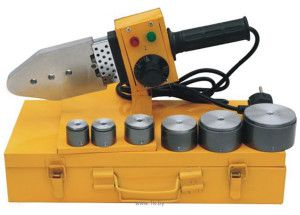

One of the advantages of heat supply from polymers is the possibility of self-welding of plastic heating pipes. To do this work, you will need a minimum of tools and at least basic skills in using them.

To form a high-quality pipe connection, including in a plastic heating manifold, you will need a soldering tool. It is a heating element on which pipe nozzles are installed. They are designed for products of various diameters. In addition, for the installation of plastic heat supply in a private house, the following tools are needed:

- Scissors for plastic pipes. They have a wide base, due to which an even cut is formed;

- Measuring tool - tape measure, building level;

- Surface degreasing liquid - acetone or alcohol;

- Chamfering device. Before welding plastic pipes for heat supply, the reinforcing layer should be removed at the end.

Before making plastic heating, a piping layout is independently drawn up, their diameter and location of heat supply components - radiators, security groups are calculated. According to this scheme, the volume of the required material is calculated and its purchase is made. After that, the pipes should lie at room temperature for 1-1.5 days. Only then is the soldering of the plastic heating pipes carried out.

Air ventilation should be provided in the room where the plastic heat supply will be installed.During soldering, vapors harmful to humans are emitted, which, with prolonged exposure, can damage the respiratory system. The procedure for installing plastic heat supply with your own hands:

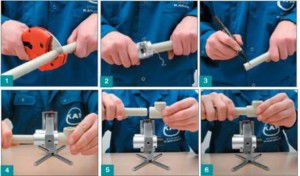

- Measure the pipe section.

- Use scissors to cut the workpiece.

- Do the same procedure with the second segment.

- Heat the soldering iron to the required temperature.

- Install the fitting and pipe into the nozzles on the heating element.

- After a certain time, take out the workpieces and join them together.

- Wait until the heating unit has cooled down completely.

According to this scheme, a high-quality installation of heat supply is carried out.It is important not to rotate the parts in the soldering iron during warming up. The same applies to the procedure for joining a pipe fitting.

When soldering pipes or a plastic heating manifold directly into the heating system, you need to monitor the condition of the elements. They should not rotate in the soldering iron nozzles, but at the same time go into them as tightly as possible.

A sharp knife can be used to remove the reinforcement layer. If the volume of work is planned to be large, it is best to use a special manual machine. Its design makes it possible to process pipes of various diameters with a sufficiently high accuracy.

The air temperature in the room must not be lower than + 15 ° С. The same applies to the degree of heating of the pipe surface.

If you overexpose the workpieces in a soldering iron, when connecting a pipe and a fitting, the diameter of the pipeline will artificially decrease due to the large volume of the guide. Insufficient heating of the surface will reduce the quality and reliability of the connection.

DIY plastic manifold for heating

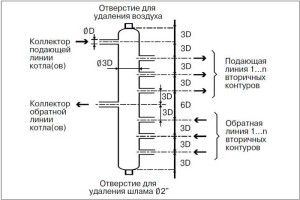

Heating system pipelines can be installed according to several schemes - one-pipe, two-pipe or collector. In the latter case, to distribute the coolant over the sections of the system, it is necessary to make a plastic heat supply collector.

The best option is the purchase of a ready-made structure. But if you have a soldering tool and a pipe of the required diameter, you can always make it yourself. To carry out this work, the dimensions of the future collector are first calculated.

They directly depend on the diameters of the connection pipes and the number of heating circuits. It is important that the cross-section of the inlet pipe is equal to the sum of the diameters of the connected circuits. Thus, it is possible to avoid the appearance of overpressure or a discharged area of the coolant in this section of the heat supply.

For the manufacture of the body, it is recommended to use a pipe with a maximum pressure rating of at least PN20. According to a pre-calculated scheme, all the necessary nozzles are installed on it - inlet and distribution. For control, shut-off and control valves are installed in the distribution of plastic collector heating. It can be of the following types:

- Ball Valves... Designed to quickly shut off the coolant to a specific heating circuit;

- Needle cranes... With their help, you can manually adjust the volume of hot water inflow;

- Thermostats... They will automatically restrict the flow of the coolant depending on its temperature and the previously set operation readings.

Additionally, a mixing unit and a circulation pump may be included in the package of the plastic manifold. This equipment will optimize the operation of the entire heating system. When installing several collectors, the heating system must be balanced. It is necessary to stabilize heat distribution and pressure in all parts of the system. For this, special balancing cranes or similar equipment are mounted.

To compensate for the thermal expansion of plastic pipes, ring elements are installed on long sections of the line. They will prevent the formation of surface tension after prolonged exposure to high temperatures.

The video describes in detail the parameters for choosing plastic pipes for various systems: