A home heating system can only provide you with maximum comfort when its design is thought out in advance. It is important to choose the right type of heating equipment and decide on the options for its installation in order to get the most convenience at the lowest cost. The most rational way to heat a house is a single-circuit heating system. What are the benefits such a system can provide in comparison with a more complex two-circuit system?

Single-circuit heating device

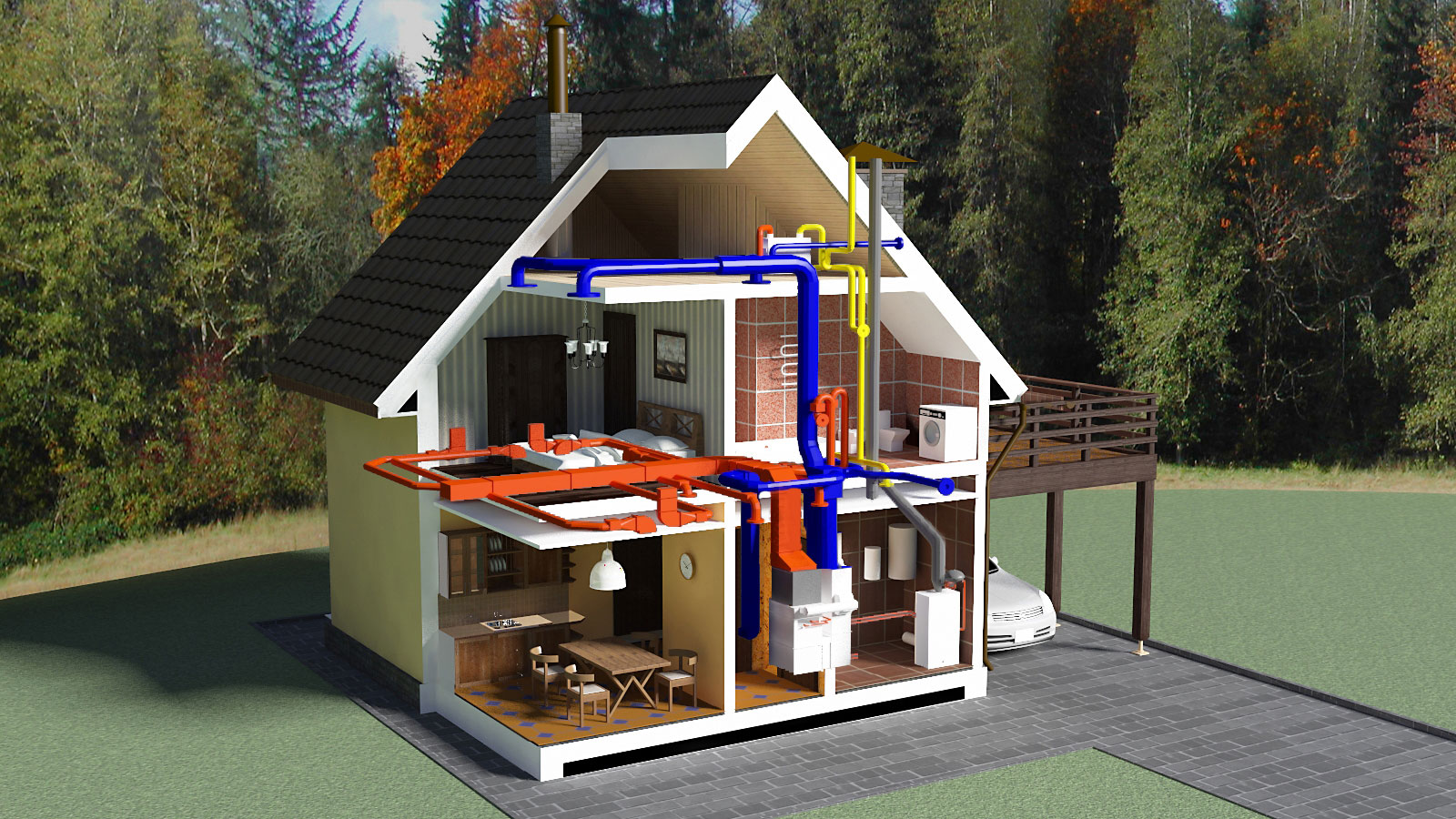

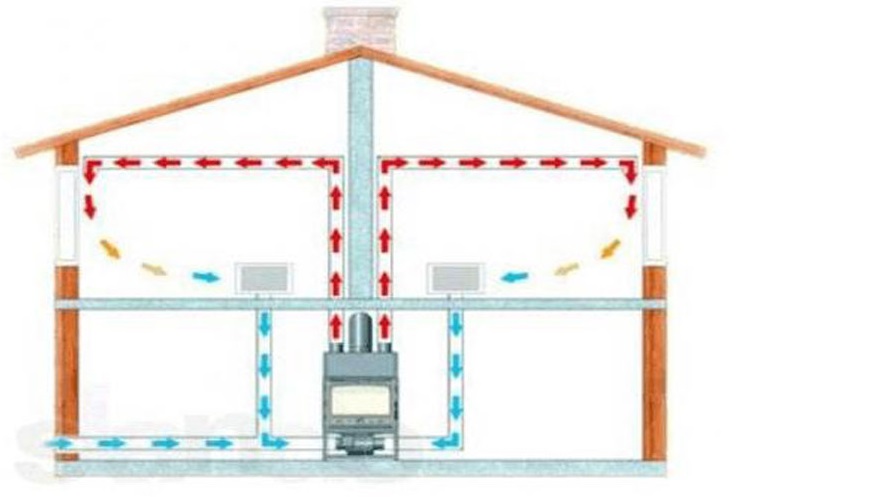

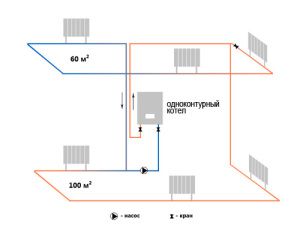

A single-circuit heating system is called a heating system, the scheme of which provides for the circulation of the coolant (usually ordinary hot water) sequentially through all its components installed in the dwelling. True, this system provides only warmth in the house, but does not heat the water for the bathroom and kitchen. But at the same time, the minimum required number of pipelines is used, thereby reducing costs.

Heating equipment consists of the following elements:

- heat generator (most often a single-circuit gas heating boiler, wall or floor);

- metal pipes through which heat is transferred;

- expansion tank, regulating pressure;

- circulation pump (if necessary);

- heat exchangers for heating each room - radiators.

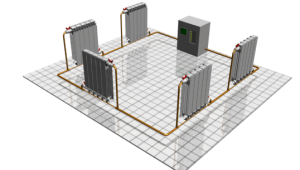

It is also possible to use a "warm floor" heating system instead of radiators, in which pipes laid under the floor cover evenly heat the room.

In order for a single-circuit heating system to function smoothly, its scheme must be developed in detail even at the design stage of the house.

Benefits of using single-circuit boilers

The advantages of a single-circuit heating system are:

- practicality of the device;

- ease of installation;

- independence from the water supply;

- reasonable price.

Owners of cottages often give preference to double-circuit heating units that can solve two problems at once: to supply the dwelling with heat and domestic hot water. However, there are situations when, for example, in a country house there is no gas pipeline and central water supply, and an electric boiler is installed to heat the water. Then a single-circuit diesel heating boiler will be the best choice. A single-pipe heating system works normally even without a connection to the water supply.

The disadvantage of a single-circuit system is called its purpose to work only for heating. But if you show your engineering ingenuity, you can improve a Russian-made single-circuit gas heating boiler. It is enough to install an additional heat exchanger in the system, and it will provide the whole family with hot water.

Another inconvenience of a single-circuit heating system is the fact that the last of the entire chain of radiators receives less heat than the previous ones. To balance the heat transfer, it is necessary to install control valves on the radiators.

Heating devices for a single-circuit system

The efficiency of the heating system mainly depends on the heating boiler.They are different, but gas single-circuit heating boilers deserve the best reviews. In most cases, this type of apparatus most closely matches the living conditions of the consumer. A single-circuit boiler is much simpler in design than a double-circuit boiler, so it does not cause inconvenience during installation and operation.

The main criterion when choosing a heating device is the amount of work that this model of the device is capable of performing. Boilers for a single-circuit heating system differ in power. Judging by user reviews, wall-mounted versions of single-circuit gas heating boilers should be considered the least powerful.

Roughly it is possible to determine the boiler operability according to the formula: 1 kW of power per 10 m² of the area of the room. A more accurate calculation can be made by professionals who will also take into account the height of the ceilings, the number of windows and many other factors.

By type of fuel for boilers, they are divided into:

- coal;

- gas;

- diesel;

- electrical.

The choice of a heating boiler should be based on what fuel is most available in your area.

Burning a home boiler with coal is still a hassle! Even if we accept that coal dust will constantly scatter around living quarters, there will still be a lot of problems. After all, you need to load coal into the furnace on time, monitor combustion, remove slag and ash. Numerous reviews confirm that the use of single-circuit gas heating boilers is much more convenient. Therefore, we will leave outdated solid fuel boilers beyond our attention.

Whether it is modern single-circuit heating boilers: gas (floor and wall) or diesel! There is no smoke or dirt from them, and they do not require vigilant control. Just light it up, set the fuel supply mode, and you can relax in the warmth!

Many models of gas heaters are manufactured in a wall-mounted version. Such devices are so compact that they can be hung even in the kitchen. But single-circuit floor-standing gas heating boilers have to be installed in a separate room, but they are more powerful and capable of heating many rooms at once.

If you are planning to install a gas or diesel type heating boiler, you need to take the fire inspection regulations seriously.

Single-circuit heating boilers are also electric. Although the price of electricity is much higher than the cost of gas, the use of electric boilers is inevitable where it is not possible to use a unit with a different type of fuel.

Let's consider the most popular types of heating boilers.

Gas boilers

Gas heating equipment is produced configured for the consumption of natural gas, however, if necessary, it is not difficult to convert it to liquefied gas. And judging by the reviews, single-circuit gas heating boilers willingly consume liquefied fuel from cylinders. The most practical homeowners, in order to stock up immediately for the whole winter, pump gas into a large underground tank (gas tank).

The whole variety of models of gas boilers fits into two categories: devices for installation on the floor and for hanging on the wall. The use of single-circuit gas floor heating boilers in private houses provides that it is permissible to install such a unit only in an annex equipped with ventilation or in a basement. However, when placing the boiler below floor level, it must be borne in mind that it will be necessary to increase the circulation of the coolant by connecting the pump.

At the present time, single-circuit wall-mounted gas heating boilers have gained great popularity. These household heating devices develop a relatively low heat output, no more than 35 kW. Their convenience is manifested in the fact that the compact device can be easily hung on the wall and connected to the pipeline.Wall-mounted single-circuit gas heating boilers are advantageous to install in small houses where hot water supply is not required.

For heating an individual house less than 300 m², a wall-mounted single-circuit gas heating boiler is quite suitable. The most "advanced" models of such devices hide under a compact body not only a combustion chamber and a heat exchanger, but also an expansion tank, a pump, sensors and control automation.

Check out the five advantages of wall mounted gas boilers:

- compactness, thanks to which the device does not take up much space;

- admissibility of installation not only in a private house, but also in an apartment;

- the ability to independently mount the elements of the heating system (except for gas, which must be connected by a specialist);

- simple control system and regulation of combustion modes;

- stylish design that matches any interior style.

At the same time, wall-mounted single-circuit gas heating boilers also cause negative reviews. Among the disadvantages, consumers note their low power and the need to often clean the heat exchanger covered with scale.

It is allowed to install wall-mounted boilers only on solid walls, preferably brick ones. In places of contact with wooden structures, it is necessary to build a heat-insulating gasket from a layer of asbestos and a metal sheet.

Diesel boilers

Heating boilers using liquid fuels are less common. But in conditions when housing construction is not connected to the gas supply, a diesel single-circuit heating boiler will be the best choice. Heating units powered by diesel fuel are capable of overtaking their gas counterparts in terms of efficiency. Diesel boilers are able to continuously provide heat even throughout the winter, while the pump pumps fuel from the tank.

By design, diesel heating devices differ little from gas ones. Some models of single-circuit diesel heating boilers can successfully operate on gas - just replace the burner. Another advantage is that a diesel boiler does not need permits, as for a gas one.

Electric boilers

In most cases, single-circuit electric heating boilers are used where it is not possible to connect to a centralized gas pipeline. In addition, it makes sense to install such a device in addition to the main boiler in case of its failure.

Comparison of electric single-circuit heating boilers with others shows that they compare favorably with their modest dimensions. Electric boilers do not need a chimney, they work without noise and dust. The modes of operation of such devices are easy to configure from the control panel.

All heating boilers, except for electric ones, take air from the room during operation and emit combustion products. Therefore, they must be installed in a separate room with effective ventilation.

The most popular brands of wall-mounted single-circuit gas heating boilers are considered by consumers:

- german - Bosch, Vaillant, Buderus;

- italian - Ferroli, Baxi, Ariston;

- french - Frisquet, De Dietrich, Chaffoteaux;

- swedish - Electrolux.

The use of Russian-made single-circuit gas heating boilers is financially much more profitable. Of these, the most demanded brands are "Signal", "Gazapparat", "AZGA". Since a significant part of domestic products are completed with imported units, our heating boilers are inferior to similar foreign products only in attractive design. Moreover, their adaptability to Russian gas and electricity networks is much higher.

Heating system installation principles

If you correctly calculate the parameters of a single-circuit heating system and mount it according to the developed scheme, your home will be warm and safe in any cold.

The stages of installation work should be as follows:

- Equip a boiler room (for a floor-standing boiler) in a room with forced ventilation and fire protection.

- Install the boiler, providing free access for its maintenance.

- Connect the boiler to the roof flue.

- Install an expansion tank (if the boiler is not equipped with it).

- Route pipes to the places where the radiators will be installed.

- Fasten the radiators to the brackets in the rooms under the window openings.

- Install temperature control fittings on the radiators.

- Connect all the elements, and then pressurize and control the system.

Only an authorized employee of the district gas service has the right to start the gas boiler for the first time, who, upon completion of the inspection, will issue a certificate of conformity to the homeowner.

During operation, it is sometimes discovered that outdated models of Russian-made single-circuit gas heating boilers cannot cope with their work due to insufficient power. Then it is advisable to connect a pump to the system, which will enhance the natural circulation of hot water.

Which of the single-circuit heating devices will be able to bring more heat into your home, while remaining convenient, economical and safe? A video consultation will help you make the right choice.

So, decide according to your needs: will you have a compact gas boiler, or a powerful diesel unit like a locomotive. The main thing is that its operating parameters consistently provide you with comfort in the house.