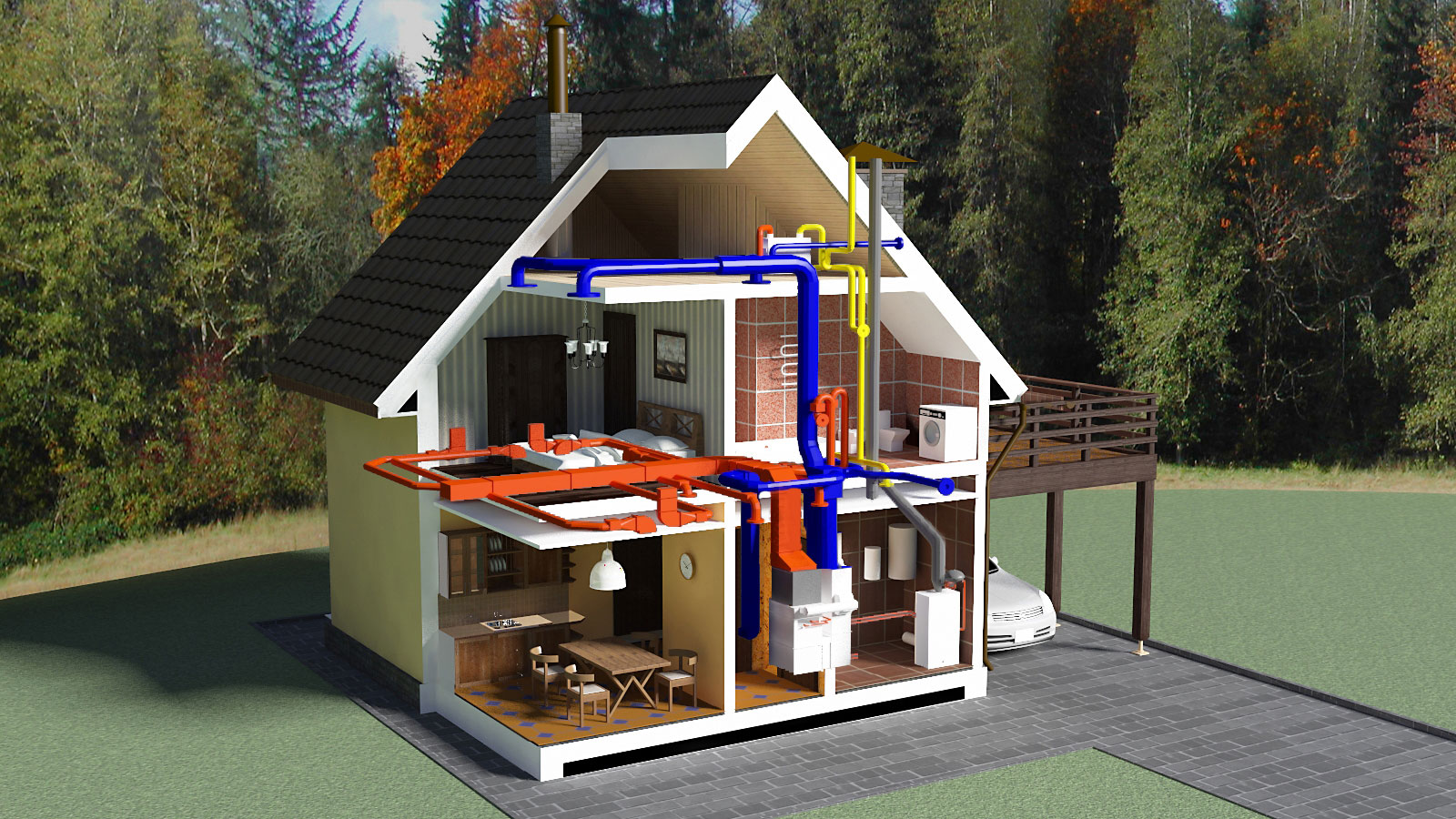

During the planning of heating, they try to provide for all possible nuances and factors. An important one is the type of ebb tide used. Therefore, in order to increase reliability and reduce the cost of maintenance, combined boilers for heating a private house have recently been increasingly chosen.

The relevance of the installation of combined heating boilers

The main difference from standard models of heating equipment is the ability to use several types of energy carrier. Modern combined boilers for home heating can operate both on gas and on solid and liquid fuels. But models with built-in electric heating elements have gained particular popularity.

Heating a country house with a combined boiler can be relevant in several cases. First of all, the choice is determined by the possibility of using several types of fuel and their cost. In some periods of operation of the heating supply, it will be beneficial to use firewood instead of diesel fuel. The same applies to natural and liquefied gas, electricity.

Combined universal heating boilers are installed in the following cases:

- Reducing the inertia of the heat supply... The initial start-up of electric heating will allow you to quickly heat the water in the system. Solid fuel or gas can be used to maintain its temperature at the desired level;

- Independence from power supply... Many foreign and Russian combined heating boilers have the ability to use a certain type of fuel without being connected to the mains - firewood, coal;

- Economical consumption... In the absence of the main energy source, combined gas heating boilers have the function of automatically switching to another type of fuel.

The main disadvantage that double-circuit combined heating boilers have is their high cost. This is due to the complexity of the design and the actual duplication of many components to maintain the full set of functionality.

You can determine the optimal model for completing the heat supply of a house by reading reviews about combined heating boilers. However, you should remember about their subjectivity.

Heating boilers gas-electricity

The most effective in terms of heating water in heating is electricity. The impact on the coolant occurs with a minimum delay, which entails a sharp increase in its temperature. Therefore, combined gas-electricity heating boilers are especially popular.

It is important to take into account the small dimensions of such a design. The main advantage of combined gas-electricity heating boilers is variability - the installation of several circuits (heat supply and hot water supply), the ability to connect to several heating systems.

The main advantages of combined gas-electricity boilers for heat supply are:

- Small size... The gas combustion chamber is small, and the heating element or other type of electrical heating device can be installed directly into the heat exchanger;

- Low power consumption... Such combined boilers for heating a private house mainly run on gas. Electric heating element turns on in the absence of gas, or for operational heating of water;

- Affordable cost... It is due to the absence of the need to make a separate combustion chamber, since the heating element is mounted in a heat exchanger.

In some models, when planning the heating of a country house with a combined boiler, it is possible to connect a boiler. This is true if the equipment does not have a secondary circuit for DHW.

In most cases, the power of heating elements is designed to maintain the required temperature level in the heat supply system, and not for constant operation. You need to pay attention to this when choosing Russian combined heating boilers.

Heating combined boilers wood-gas

The most economical types of energy sources are currently wood and gas. That is why it is recommended to use combined wood-gas heating boilers to organize heat supply for private houses.

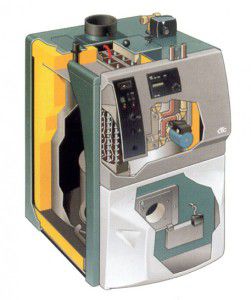

Structurally, boilers of this type have two combustion chambers for each type of fuel. This leads to the large dimensions of the heating equipment. Depending on the functional features, combined wood-gas heating boilers can have one or two heat exchangers. In the first case, they are common to each combustion chamber. In double-circuit combined heating boilers, the DHW function is performed using one of the types of fuel.

For all combined gas heating boilers, before installation, it is necessary to correctly draw up permits. At the same time, the Management Company in the Technical Conditions will focus on the technical properties of the gas component of the equipment. It is important that in the design of combined boilers for heating a house, the characteristics of the solid fuel part do not affect the gas part.

There are two types of combined wood-gas heating boilers:

- With separate combustion chambers... These are mainly factory models with two circuits. One of them heats water for heating, and the second provides hot water supply;

- With a common combustion chamber... This is more true for self-made installations, when you need to minimize the cost of arranging heating a country house with a combined boiler. The standard boiler is fitted with a factory gas burner. If firewood is used, it is dismantled.

The latest models have the most controversial reviews about combined heating boilers. Basically, these are home-made structures in which the heat exchanger is not designed for high thermal effects during the operation of a gas burner. This is what causes the frequent failure of the boiler.

When choosing a gas burner for a solid fuel boiler, it is necessary to accurately measure the dimensions of the combustion chamber. They must match the dimensions of the gas burner.

Heating combined boilers wood-electricity

In the absence of the possibility of connecting to a gas main or organizing cylinder heating, solid fuel boilers are most often used. They are non-volatile and have a fairly high power. However, for the unification of heat supply, it is recommended to use combined wood-electricity heating boilers.

Structurally, they are in many ways similar to the above-described gas models. The difference lies in the possibility of self-production of a combined heating boiler, firewood, electricity. This work can be done without the involvement of socialists.It is enough to choose a heating element of the required power and install it in the heat exchanger of a universal combined heating boiler.

There are ready-made factory models on the market with a full set of required equipment. Unlike homemade boilers, they have precisely calculated the location of the heating element, its power. The main indicator is complete operational safety. In addition to these indicators, the following features of combined heating boilers for firewood electricity should be noted:

- Possibility of connecting additional devices... Often, manufacturers provide a contact part for connecting the heating element unit with a programmer or thermostat. Options for remote control of the boiler can be considered;

- Reliability of work... In factory models, combined boilers for heating the house are mounted with special heating elements, which are not susceptible to breakdowns with a large thermal effect from a solid fuel furnace;

- Maintainability... If the electrical part fails, you can replace it with a similar one yourself. Alas, combined gas boilers for heat supply in most cases do not have this function.

To select a combined boiler for heating a private house, firewood-electricity, you must first calculate the power of the heating element. Experts advise models in which this figure is at least 70% of the required for heating a private house.

The power adjustment of a solid fuel boiler is extremely slow. Therefore, if it is necessary to quickly change the degree of heating of the coolant, it is recommended to activate the electrical part of the equipment.

The device of combined furnaces for heating

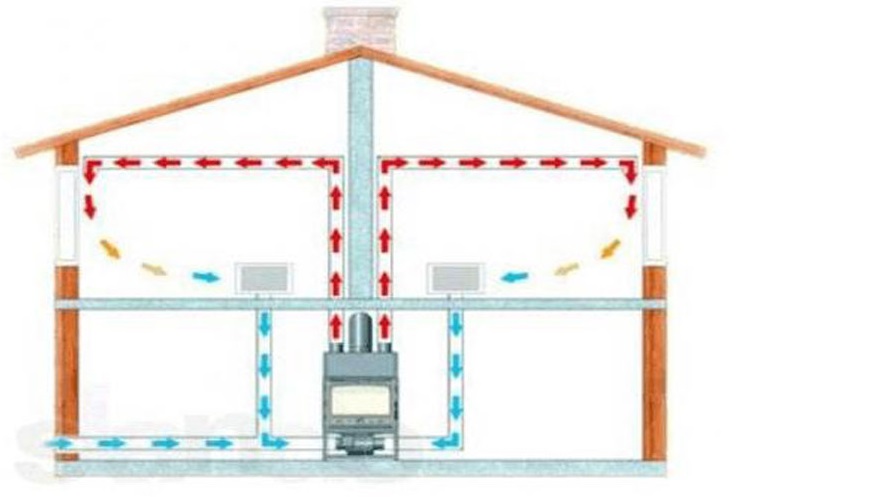

The use of brick ovens is the traditional way to heat a small home. But even in this case, it is possible to improve the standard design by making a number of changes. Currently, there are modern combined stoves for heating a house, which ensure the stability of the system and a high efficiency.

The advantage of the brick construction is not only the possibility of using several types of fuel (wood, gas, diesel), but also the possible modification of the device.

In contrast to the heat supply of a country house with a combined boiler, several heat exchangers can be made in a furnace, a rough one can be equipped, and a boiler of indirect or direct heating can be installed. However, each such innovation will directly affect the dimensions of the structure.

Recently, the following modifications of combined stoves for heating a house have been made:

- Installing the hob... This is a classic way to improve functionality. In addition to heat supply, you can cook food on the stove;

- Burner installation... For this, you can use a gas or solid fuel burner. But it is best to use gas models, since with normal traction indicators they do not create an unpleasant odor in the room;

- Heat exchanger for hot water heating... By installing a tubular structure in the firebox, you can make a small but effective heating system for your home. It is necessary to take into account its great inertia - heating of water in combined stoves for heating the house and heating of water in pipes will be slow.

Even less often, you can find double-circuit combined heating boilers in furnaces. This is due to the small size of the heat exchanger. To provide hot water supply, it is best to install a tank for direct or indirect heating of water.

Regardless of the design of the furnace, before erecting it, you need to make a separate foundation that is not associated with the general house. This measure is necessary due to the large mass of the structure, as well as the chimney system.

Universal combined heating boilers

In some cases, it is advisable to use universal heating boilers, which provide for the use of not only two types of fuel. These include heating boilers, combined gas-wood-electricity, pellet models.

The defining difference that pellet combined heating boilers have is the presence of several combustion chambers. They are adapted for the use of a certain type of fuel - gas, diesel, firewood, etc. As an additional measure, an electric heating element can be provided, located in one or more chambers of the heat exchanger.

It is noteworthy that in many models of combined heating boilers, gas, firewood, electricity, the pellet burner is removable. Those. the combustion chamber for it can be used for another type of fuel. Most often it is gas or diesel. The conditions for the use of these energy carriers provide for the presence of forced air injection and a complex design of a heat exchanger for transferring thermal energy. These qualities are also characteristic of pellet combined heating boilers.

For the operation of multi-fuel heating boilers, the following conditions must be met:

- Stable power supply... It is needed for the operation of pellet combined heating boilers, gas and diesel burners. The exception is the use of solid fuels;

- Organization of fuel delivery to the boiler... The main problem in planning the installation of gas-firewood-electricity combined heat supply boilers is the storage of energy carriers. For balloon heating, separate rooms are made or external steel boxes are installed. Diesel fuel is stored in barrels, which are connected to a special pumping station.

Before purchasing universal boilers for combined heat supply, you should analyze the feasibility of their use. Their cost is an order of magnitude higher than classic single-fuel ones. For this, a detailed financial analysis is made for each type of energy carrier.

When installing foreign and Russian combined heating boilers, you need to correctly calculate the diameter of the chimney. The thrust rating must meet the minimum requirements for each type of fuel.

Reviews of the owners of combined heating boilers

An additional way to determine the relevance of using a particular combined heating boiler is a detailed study of reviews. They will help to anticipate possible problems during installation and operation in advance. It should be noted that not all reviews of combined boilers for heat supply are positive:

- Even 15 years ago, during the construction of a house, he provided for the installation of two boilers - gas and solid fuel. Over time, I began to notice that servicing everyone is becoming more and more expensive. I decided to try a combined gas-firewood boiler. The result was more than good. Heating operation was almost completely automated, failures stopped;

- I have been looking closely at the gas-electricity boiler for a long time. The only obstacle to buying it was its high cost. Finally I made up my mind and bought it. In practice, the boiler efficiency turned out to be lower than in the passport. There may be a gap in the heating circuit. I plan to call specialists to analyze the situation;

- It is planned to supply main gas to our village in two years. I decided to prepare in advance for this event and purchased a boiler that runs on gas and coal. After the first heating season, only positive impressions. It remains to wait for the gas connection and check the operation of the equipment on it.

Regardless of the type of combination boiler, before purchasing it, you need to carefully consider the entire heat supply system. This applies to the piping system, flue ducts and the heating safety device.Together, they must provide normal heating of the house at optimal energy costs.

In the video, you can see an example of the operation of a pellet combined boiler for heating a house: