Despite the fact that the stove for a bath from a pipe does not look very aesthetically pleasing, it fully copes with its duties - it quickly and efficiently heats the air in the steam room. This design has an undeniable advantage over other options - the oven can be made independently and rather quickly, saving money and time. The stove made of a pipe is also favored by its compactness and excellent heat capacity.

Pros and cons of homemade construction

The materials used for the manufacture of steam room stoves must have the following qualities:

- heat resistance;

- mechanical strength;

- corrosion resistance;

- resistance to sudden temperature changes;

- durability;

- high thermal conductivity and heat capacity.

Ferrous metal is not characterized by high resistance to the formation of corrosion, however, the manufacture of a bath stove from a thick-walled pipe is possible if its diameter is at least 50-60 cm.

The advantages of this design:

- Ferrous metal is characterized by excellent performance characteristics: mechanical strength, high heat transfer rate and resistance to temperature extremes. At the same time, the linear thermal expansion of the material is low.

- The thickness of the pipe is at least 8 mm, which provides a high thermal capacity of the structure, which can retain and gradually release heat for some time even after the fuel has burned out.

- The large thickness of the material extends its service life, despite the fact that the metal is susceptible to destructive corrosion properties.

- The stove has excellent natural draft, efficient distribution and extraction of heat energy due to its internal cylindrical shape.

- The number of welds is minimal due to the round shape of the product. Therefore, the likelihood of corrosion, smoke leakage and carbon monoxide is minimized.

- The cost of a used pipe is low compared to a new one. The main thing is to carefully check it for corrosion before buying.

Pipes are different depending on the manufacturing method. The best option would be hot rolled seamless pipe or electrofusion pipe with one longitudinal seam. Products with a screw seam are not suitable, as they are deformed as a result of strong heating.

The main disadvantage of a homemade metal oven is the intense infrared radiation. A person feels it as a strong heat, so being close to the stove can cause discomfort. At the same time, the very presence of such heat does not mean the same effective heating of the room.

Installation Requirements

Before making a stove from a pipe, it is important to decide on the type of construction. To do this, it is necessary to take into account personal preferences and parameters of the room - area and layout.

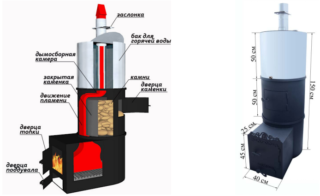

In a small-sized steam room, a compact design with vertical placement will be the best option. Such a stove is equipped with a firebox, a stove and a water heating tank.

The appearance of a vertical stove for a bath made of a thick-walled pipe can be compared with a classic potbelly stove.

Basic requirements for installing the oven:

- the distance from the outer surface of the pipe to the walls must be at least 20 cm;

- the structure is installed on a pre-prepared base;

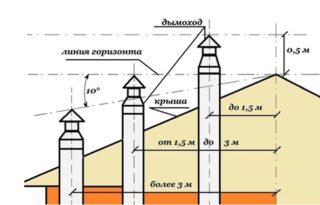

- at the site of the exit of the chimney from the room, a thickening of 12 cm is made;

- the pipe section located in the under-roof space is covered with a lime mortar;

- the ash pan should be located 15 cm from the floor;

- the floor area in front of the ash pan is sewn up with a metal sheet or other heat-resistant material;

- from the outer surface of the roof to the outlet of the pipe, the distance should be at least 50 cm.

Before installation, the oven is checked for cracks and gaps - the structure must be completely sealed. The wooden sheathing in the steam room must be treated with protective compounds. It is not allowed to place flammable materials with plastic, wood or textile surfaces near the stove in the immediate vicinity.

Self-manufacturing methods

When deciding to independently make a stove into a bath from a pipe, it should be borne in mind that there is no need to talk about the stylish appearance of such a design. However, it fully fulfills its functional purpose, quickly and efficiently heating a steam room with a volume of up to 20 m3.

Structurally, do-it-yourself sauna stoves from a steel pipe are divided into vertical and horizontal. Each variety has its own pros and cons. The main criterion for choosing a particular modification should be based on the area and layout of the steam room.

Horizontal arrangement

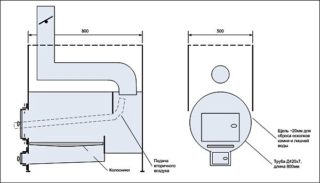

If it is fundamentally important to keep free space in the steam room, a vertical design should be chosen. But the horizontal oven has several obvious advantages:

- convenient location of the firebox;

- the optimal height of the heater due to the low height of the structure itself;

- excellent heating of stones and a water tank;

- the low weight of the structure allows it to be installed in the center of the room on an ordinary steel sheet, 8 mm thick, provided that the insulation is 20 mm thick;

- even distribution of fuel.

The material for the manufacture of a horizontal structure can be a pipe with a diameter of 50 cm or an old gas cylinder.

The peculiarity of such a stove is that it perfectly heats all parts of the steam room, except for the floor.

Vertical arrangement

The level of heat transfer and burning time for a vertical stove into a bath from a pipe is lower than that of a horizontally installed structure. This is due to the fact that thermal energy tends upward, not having time to warm up the metal walls.

The combustion rate of fuel inside a vertical structure can be reduced by closing the ash pan door and thereby limiting the access of oxygen to the furnace. Another disadvantage is that in a vertical furnace the fuel burns out entirely at once, and in a horizontal one - gradually, ensuring uniform heating of the room. The advantage of the vertical design is that the stones are heated more intensively and more saturated steam is obtained.

The efficiency of a horizontal furnace is higher, so it is more expedient to choose such a design. To give the stove an aesthetic appearance, it can be bricked, painted or blued.

When choosing a composition for painting a metal surface, its heat resistance should be taken into account. The paint will solve the problem with the appearance of the furnace and protect the metal from corrosion. The texture and color of the composition affects the heat transfer - a matte dark surface gives off heat energy better than a smooth glossy one.

The heated metal emits scalding infrared radiation. Brickwork will protect against it, which will absorb heat and gradually release it into the room.

There are several options:

- with a solid lining, the furnace can be made aesthetically pleasing, but its heating efficiency will decrease to some extent;

- to increase heat transfer and create more comfortable conditions in the immediate vicinity of the stove, you can use a small brick heat shield;

- universal options include a convector cladding device with air vents.

The treatment of a metal surface with special chemical compounds is called bluing. This decoration method provides, in addition to the aesthetic appearance, reliable protection against corrosion.

Features of the drawing

In order to choose the right way to position the stove in the steam room, it is preliminarily recommended to complete a drawing of the room and the structure itself in order to understand how much space is required to place it.

Structurally, the sauna stove consists of elements sequentially fixed by means of welding:

- blower body, heater, firebox and grate;

- container for water;

- chimney;

- a spark arrester on the chimney.

The choice of a pipe suitable for a particular design is influenced by the thickness of the steel and the size of the internal section of the product. The marking "diameter * wall thickness" will tell you about the parameters of the product. For a sauna stove, the preferred value of the diameter is 50-60 cm, and the wall thickness is 0.7 - 1.3 cm. Such walls are best machinable and do not deform during operation under the influence of high temperatures.

More often for these purposes, a pipe with a cross section of 53 cm is purchased - this value is considered the most optimal for a steam room. A small oven with a diameter of 42.6 cm can be installed in a small sauna room, which mostly serves as a washing room. For a spacious steam room, a pipe with a cross section of 63 cm is suitable.

When choosing the diameter and height of the structure, it is necessary to take into account the area of the steam room and the planned amount of fuel. The larger the firebox, the faster the fuel will burn out and more heat energy will be released.

Possible errors during the manufacturing process

If the finished structure does not work as we would like, most likely a mistake was made during the manufacture and installation of the furnace.

If there is a rapid removal of heat from the stove, a movable valve must be installed inside the chimney.

A large accumulation of soot inside a horizontal oven can ignite it. An afterburner in the form of two metal tubes bent towards the pipe, installed on one of the walls of the structure, will help to solve the problem. As a result, the amount of soot will decrease, and the furnace will be better saturated with oxygen, as a result of which the firewood will completely burn out.

Operating tips

Hot metal is dangerous for severe burns and fire. Therefore, you should follow simple rules:

- Homemade metal stove is primarily compact and lightweight. But this should not affect the refusal to manufacture an individual foundation for the structure. The height of the base must be at least 20 cm from the floor surface. The material for making the foundation can be monolithic reinforced concrete, solid concrete blocks or brickwork.

- The area of the floor in front of the firebox with a blower is covered with a metal sheet measuring 50 x 70 cm.

- The opening of the doors should be directed towards the entrance of the steam room or dressing room.

- There must be a free distance of at least 100 cm between the chimney and other hot metal structural elements and the wooden walls of the room.

- The tank must be filled with water before starting the sauna firing. To avoid steam shock and thermal injury, do not fill the tank with water while the oven is running.

- Condensation with an aggressive chemical composition forms on the inner wall of the chimney. To reduce its amount, the chimney pipe is insulated from the outside with mineral or basalt wool. The thickness of the insulation should be at least 8 - 12 cm. On sale you can find ready-made chimneys in the form of a stainless steel sandwich pipe.

The independent manufacture of a stove for a bath attracts with the low cost of the product and the ability to take into account your own preferences as much as possible, as well as the parameters of a single room. A metal stove can help out at the stage of construction and modernization of a bath with a capital brick stove or during the construction of a temporary washing room.