A country stove is a device for heating a room and cooking food. There are different projects of heating devices, some of them differ in volume and massiveness. The choice is determined by the heating area. A brick oven is one of the most effective devices that meets the standards and requirements of GOST and SNiP. You can build a brick oven for a summer residence with your own hands if you have the skills and abilities according to existing schemes and drawings.

Criterias of choice

The selection of a suitable oven depends on many factors. They affect the design of the device, dimensions, characteristics.

Size and shape

The size of a brick stove for a summer residence depends on how much area it can heat. Stoves can be used to heat a room and act as a dividing wall between two rooms. For small rooms, you should choose a compact miniature device. They have less functionality, but will not take up important space.

Great attention is also paid to the choice of fuel. Usually brick ovens are fired with wood, but other raw materials (coke, coal) can also be used.

It is important to select the location of the heater in advance. It should be borne in mind that the side walls give off more heat than the back. This factor should be considered when planning the installation in a particular location.

Stoves come in a variety of shapes. You can purchase or create a rectangular model, T-shaped, with a ledge-stove bench or a plate.

Equipment

Furnaces are also different in design. The most famous are Dutch, Swedish, potbelly stove and Russian. According to the configuration, they are distinguished:

- Heating stoves without additional elements. They do not include a hob or hot water tank. They consist only of walls, chimney, firebox and chambers.

- Heating and cooking products also have a stove on which you can cook food. Sometimes they are equipped with an oven, drying chamber, water heater.

- Fireplace stove. Has two fireboxes - stove and fireplace, which can be used simultaneously or separately.

- Combined ovens. They include the whole range of necessary functions. They are often equipped with a couch that can be used as a bed.

The cost of the furnace and the complexity of its creation depend on the functionality. It is recommended to independently build the simplest model without additional elements.

Place of installation

Several factors influence the choice of the place for installing the stove in the country with their own hands:

- Being close to the front door. The heat from the heater will block the cold outside air. In addition, when the door of the firebox exits into the hallway, it is more convenient to deliver fuel to it.

- Free access to any of the walls must be provided. This will allow you to control the integrity of the walls and clean the chambers.

- The stove needs a separate foundation that is not connected to the base of the house.

- The chimney must pass between the beams without bumping into them.

- There must be a heat-resistant flooring on the floor in front of the oven door. This is done to ensure fire safety.

The user must have easy access to the oven. At the same time, it should be located so as to heat the room as efficiently as possible.

Basic design

- Fuel chamber.It contains fuel. It is separated from the blowing chamber by a grate in the form of a lattice.

- Blowing chamber. Responsible for adjusting the air supply. It is a collection point for ash.

- Oven, hob, water heater are additional elements that are built into the oven.

- Cleaning chambers. Soot settles in them.

- Chimney ducts. Through them, smoke is removed to the street. The chimney pipe can end with a house or other type of hoods.

The most important prerequisite for efficient operation is good traction. To do this, it is important to follow the installation scheme and periodically clean the oven during operation. The height of the pipe and its correct position on the roof must also be respected.

Materials for the construction of the furnace

Self-assembly of even a small oven is a rather complicated process. To do this, you need to know how the device works, be able to pick up materials and fold them, as well as read the drawings.

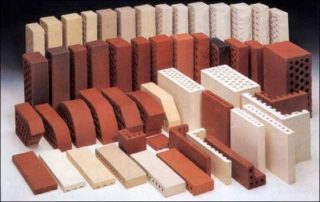

If the master decided to create a brick oven with his own hands, he will need:

- Red refractory brick. Its quantity depends on the selected model and the size of the stove. Transportation must be carried out carefully, as the material is fragile.

- Fireclay bricks for laying the firebox. Quantity - from 40 to 200 pieces, depending on the model.

- Clay mortar for brickwork.

- Cast iron parts. Doors, latches, grate are made of cast iron. They will be fastened in the masonry on a steel wire.

- Asbestos sheet.

It is recommended to buy all materials in a specialized store so that they correspond to the declared characteristics.

Styling specifics

The main components of the kiln solid are the body, the firebox and the chimney. Red brick is used in the masonry of the hull. The internal cladding is made of refractory bricks. The body with chimneys is laid on a mortar of clay and sand. You can make it yourself or buy a special mixture at the store.

When laying, the thickness of the seams must be kept to a minimum. Facing seams should not exceed 2-3 cm, in the masonry of the body and channels the limit is 5 mm. For the structure to be durable, it is important to observe the dressing of the seams. Before performing masonry work, bricks should be soaked in a container with water. Then they will not draw water from the solution.

When creating a furnace, the master must observe the following rules:

- It is necessary at each stage to check the horizontal line and the diagonal. If deviations are found, the previous rows are disassembled and errors are corrected.

- The joints should be completely filled with mortar. Surplus is removed.

- The inner surface of the chimney should be wiped with a moistened brush.

It is recommended to first do dry masonry without mortar. After checking the position of the bricks and the rowing, they are laid with a binder mixture.

Laying of a simplified Russian stove

The Russian stove belongs to the cooking and heating equipment, therefore it has a cast-iron panel for cooking food. Also, such a device has compartments for baking bread. There are three of them in the proposed scheme.

The design has an ash collector, which is located under the waste disposal. Ash is collected through a brick street channel, which is installed under the grate.

Under the foundation, 85 cm soil is chosen. The bottom of the mine must be covered with sand and tamped down to a layer 10 cm thick. A metal case is placed on top, in which 4 rows of brickwork are placed. Waterproofing is carried out at a distance of 12 cm from the floor. A waste disposal system is constructed from it, which is a hollow foundation.

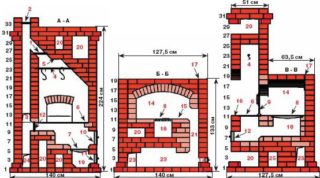

The size of the finished device will be 77 × 116 cm, or 3 bricks wide and 4.5 bricks long.

The scheme according to which a small do-it-yourself brick oven is laid:

- The initial rows are laid and a channel for ash removal is made. It is performed to remove residues from the outside of the foundation.

- After 4 rows, a metal corner is placed on the walls. It is needed to create a channel.

- 5th row - overlapping the channel from above the corners.

- A sheet of asbestos is placed in front of the 7th row.

- After row 7, the channel is sheathed with a sheet of metal.

- From 5 to 13 rows, waste disposal is made.

- 8 row - installation of metal strips.

- 9, 11, 13 rows - brick laying on the edge when forming waste disposal.

- After row 14, the furnace coincides with the level of the floor, which is sheathed around with sheet steel.

- Starting from the 15th row, the structure is placed in a metal case.

- 16 row - installation of a flap for ash removal and removal.

- In rows 17 and 18, steel strips are laid to fix the door. Also, in the 18th row, the masonry of the overlapping of the waste disposal is carried out.

- 19 row - stacking the corners for the grate.

- 20 row - laying of a metal frame with a door for cleaning the oven.

- Metal stripes are placed above the 22nd row.

- 23 row - from refractory bricks.

- Above 23 row make the hob.

- 25 row - from refractory bricks. A door for the damper is installed.

- 26 row - the formation of a chimney. To do this, in the left rear corner, the bricks are placed on the edge. The masonry is reinforced with steel strips. Also, at the level of the row, metal sheets for baking bread are stacked. There should be 3 of them.

- In front of the 28th row, a bedding of bricks is made in the place where there will be a compartment for baking bread.

- 31 row - a hole is made for cleaning. Reinforced with a steel strip.

- 33 row - creating jumpers.

- 34 row - installation of a steam exhaust damper and view.

- In row 37, the lower inner edge is cut off at the bricks. This is necessary to increase the cross section of the chimney. Also put pipes from 5 laid flat bricks. Connects by ligation with 31 row.

- Row 39 - laying an asbestos sheet. Is an insulating gasket. This is the last row of the oven.

After row 39, a smoke channel is made, which can be made of concrete or ceramic blocks to speed up the process.

This concludes the work. Next, the small stove is inspected visually and tested.