For heating a house with a large area, consisting of several rooms, it is worth choosing the most economical option, for example, a stove with a boiler. A modern brick oven with a water circuit makes it possible to heat all rooms from one point. The heat carrier in it is able to evenly distribute heat and maintain the desired temperature throughout the entire area. Before buying such a unit, it is necessary to study in detail the principle of its operation, all the pros and cons, as well as the connection method and type of system.

Method of work and design

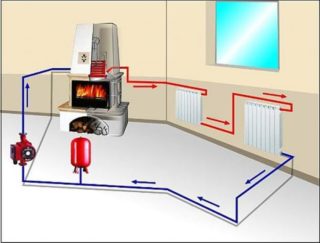

A brick oven with a water circuit for heating a house works according to a standard principle. To install it, it is necessary to create a system for water heating, with the help of which heat is supplied from the furnace walls and heating radiators connected to the main circuit. The loop pipes are connected to a boiler or a register built into the furnace. The heat carrier is heated by passing through a hot register, then it goes to pipes and radiators.

Having passed through the circuit, the temperature of the coolant decreases and it enters the heat exchanger again, where it heats up again. For ideal circulation of fuel, a special pump is built into the circuit. An important element of the system is the expansion tank. If we are talking about a closed system with a sealed circuit, such an element can be installed anywhere. In an open system, the tank is placed at the highest contour point, it can be an attic or another room.

Expansion tank - a container for excess heated coolant. It has a varied design, size and volume; it must be selected taking into account the type of heating system and the amount of heat carrier.

Pros and cons of heating with a water circuit

Brick stoves with a water circuit used to heat a private house have their advantages and disadvantages. They must be taken into account when choosing a similar device for a bath or living room. You need to choose the right model taking into account the specific parameters of the house. The best option would be a long-burning stove, capable of operating for 12-14 hours after one fuel fill.

The list of advantages of a furnace with a water circuit includes:

- economical fuel consumption in comparison with systems operating on other energy carriers;

- the ability to install a stove complete with other heating systems;

- the stove's ability to successfully fit into any interior design project.

Of the disadvantages of such units, they note the need to heat the stove in winter in a continuous heating mode. Otherwise, the rooms will not be warmed up to the optimum temperature.

The furnace with a water circuit is not an automated system, therefore, fuel for heating in some models of units must be loaded manually.

System types

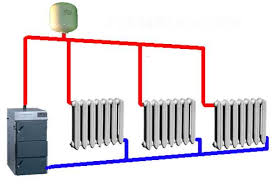

A brick stove with a water heating boiler, made by hand or purchased, can operate on a system with forced or natural circulation. Each of the two types has its own characteristics and differences that need to be considered.

Forced circulation

A system of this type is complemented by a circulation pump, which is responsible for moving the heat carrier through the chimneys. By connecting the system to electricity, the pressure level in the radiator can be controlled using valves. This also makes it possible to reduce the amount of fuel for heating the coolant. Forced circulation is quite economical, but its main drawback is dependence on power supply. In the event of a power outage, it will not work.

Natural circulation

The natural circulation system works by applying the laws of physics. During operation, the coolant moves through the pipes due to the density differences between cold and hot water. The main advantage of the system is energy independence, so it is often created in homes where there are power outages. Among its shortcomings, they note the need to use heavy metal pipes, for example, cast iron, which are difficult to mount. Also, the system does not have the ability to adjust the heating level of each room.

A stove or fireplace with a water circuit can be made of cast iron, steel or brickwork. The appropriate option is chosen by the owner of the house. During the selection, the total area of the premises that needs to be heated, the power of the device, the amount of space allocated for the stove, the location of each element of the circuit, the functions of the unit and its design are taken into account. In addition to these parameters, you need to remember about the need to install a special foundation under the stove.

Connecting the stove to a hot water heating system

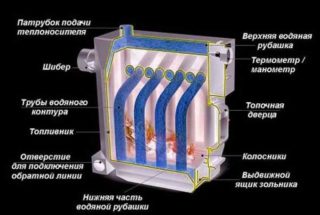

To fully connect the device to the general system, you will need to purchase a coil for the water heating stove. It is installed inside the firebox. When choosing it, the thickness of the walls of the stove is taken into account, if we are talking about a device that runs on wood, the walls can be thinner.

Units that are fired with coal briquettes can have denser walls. This condition cannot be ignored, otherwise the boilers will quickly burn out, and they will have to be replaced before the expiration of the prescribed service life.

Calculation of power and dimensions of heat exchangers

The power of the heat exchanger depends on the materials from which it is made. If the part is cast iron, models of the MC-110-300 and MC-90-300 series will be the best choice. Due to their small size, they easily fit into the firebox, their heating area for each rib will be 0.14-0.16 m2. Taking these figures into account, you can calculate how many sections are needed to heat each circuit. For every 10 square meters of premises, 1 kW is needed, equal to approximately 0.1 m2 of the total heating of the heat exchanger.

How to make a stove with your own hands

Sometimes it becomes necessary to equip a brick oven with your own hands and build it into a niche or install it on a square or rectangular foundation. First of all, markings are made for the furnace and the foundation is poured. After it dries, two rows of brickwork are laid out according to the ordering scheme in order to level the uneven foundation and make the base for the unit. Next, you need to lay out the rows on clay mortar and finish laying out, taking into account the thickness of the seams between the rows in the process.

When the body is ready, it remains to install the doors, firebox, hob, heat exchanger and other parts. After the end of the work, the oven must be fully heated and its performance checked.

Drawings for the oven can be developed independently or you can turn to professionals for help.In the absence of experience, it is better to entrust this work to specialists who will prepare a detailed diagram, taking into account the requirements for the heating system and a specific room. In this case, the finished unit will fully comply with the safety requirements and criteria for the heating system.

Do not try to save money and do it yourself, the miser pays twice

Everything is fine, but where is the stove. on which you can put the kettle

You can get rid of continuous heating by including a heat accumulator in the heating system. They are available for sale at the rate of 50 liters per 10 sq. M. As the boiler itself, it is convenient to use two cast-iron batteries of the 140 series, only they need to be sorted out by pulling the nipple onto an asbestos cord instead of rubber seals.

the valve must be inserted as close to the ceiling as possible

The efficiency of this tubular system is low compared to the register

Aftor, well, why drown the whole day, in the house instead of the walls of the board. A hut or what?

The pipes quickly burn out, it is necessary to install cast-iron radiators from heating, only they need to be disassembled and the sealing gum removed and instead of them the nipples should be wrapped with an asbestos cord and the supply pipes are the same.