When choosing the main functional component of a solid fuel heating system, in addition to efficiency, attention is paid to the duration of operating cycles and ease of maintenance. To implement the plan, taking into account the noted details, a rocket furnace is suitable. The simplicity of the design implies the absence of excessive difficulties in the independent performance of working operations.

Varieties of rocket furnaces

The specific name is explained by the characteristic hum, which resembles the roar of a rocket launching engines. In more advanced designs, with the correct setting of the operating mode, the noise is reduced to a minimum level.

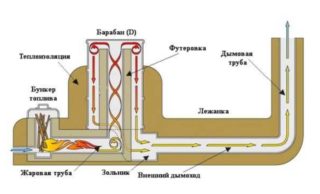

The classic diagram demonstrates the features of a reactive stove. In this design, the fuel is loaded vertically. The flame is formed in a horizontal section. With a sufficiently strong air supply, the jet of heated gases quickly unfolds by the wall of the main chamber. This provokes a vortex effect in the central part (riser), increasing thrust. The walls are heated in the side channels. Residual heat is accumulated in the lining of the outlet pipe connected to the chimney. This part is traditionally created in the form of a stove bench.

The rocket furnace has the following advantageous characteristics:

- high efficiency;

- the possibility of using wood waste, cones, other types of solid fuel;

- prompt loading without interrupting the combustion process;

- lack of complex elements;

- minimal waste (high temperature).

For objectivity, it should be noted the disadvantages of the rocket stove:

- the use of a water heat exchanger impairs the characteristics of the operating mode;

- in certain situations, it is possible for carbon monoxide to enter the room;

- the capacity of the structure is not enough to fully heat a large property.

Not everyone likes the appearance of such a structure. However, this parameter largely depends on individual tastes. With the correct finishing, it is not difficult to ensure harmonious compliance with a specific interior style.

The reactive furnace in various modifications was used by the population of Japan, China, Korea and other countries. Modern analogues, while maintaining the basic principles, differ:

- a variety of designs;

- the use of new materials;

- accurate engineering calculation.

As an example, some stove-makers mention the Chinese Kan. However, this design is similar only to a long chimney, which was often installed under several couches along the walls. In the corresponding version, this part performed the functions of a modern "warm floor" system. The firebox was created in a standard scheme with the obligatory device of a stove for cooking.

Russian stove

When simplified as much as possible, you can get the desired result:

- pipes are connected at right angles;

- a shelf for fuel is installed in the horizontal part - 60% of the diameter lower from the upper edge;

- the lower part of the hole forms an unregulated blower;

- the device is equipped with supports for fixation on a horizontal surface in a working position.

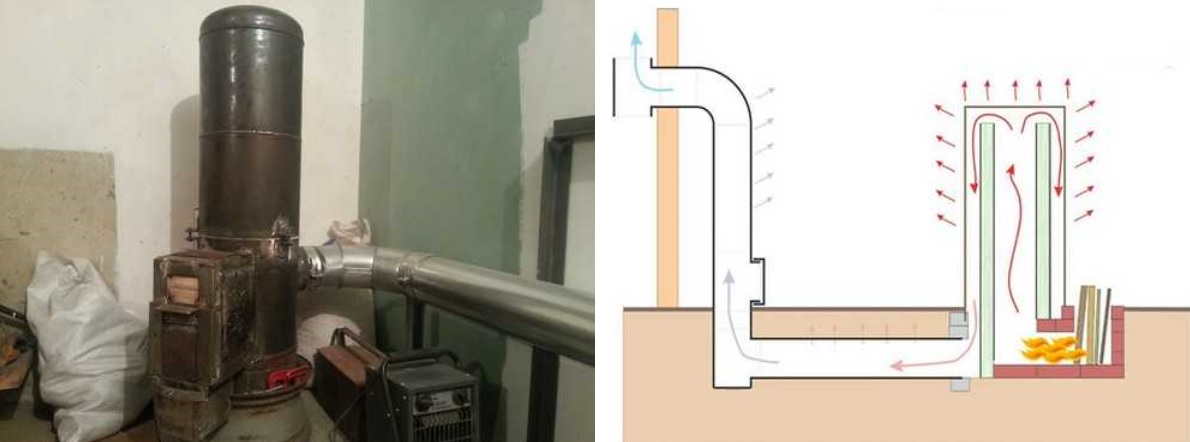

Gas cylinder oven

A factory product made of quality metal is a good basis for creating a homemade structure.In addition to reliable welded joints, the gas cylinder is suitable for wall thickness.

When choosing accessories, use sheet metal with a thickness of at least 5-6 mm. The diameter of the main part of the structure is more than 30 cm. The door in the opening for fuel loading can be used to regulate the intensity of the air supply. This addition will prevent carbon monoxide from entering the room. If you intend to use an oven for cooking, cut off exactly the top of the cylinder along with the valve. The hole is closed with a steel plate with a thickness of more than 5 mm, which is attached to the main body by welding.

In the version without a lounger, residual heat is not accumulated, therefore the efficiency is lower compared to the “classic” version of the stove.

It is recommended to insulate the inner chamber. Thick enough walls will help ensure the temperature rise to + 950C ° and above. This is necessary for high-quality reproduction of the technological process. With such heating, complete combustion of the fuel with a minimum amount of ash is ensured.

Shirokov-Khramtsov furnace

This Russian modification is an improved version of the classic scheme. The main components of the Shirokov-Khramtsov furnace are created from an expensive type of concrete that is resistant to high temperatures. Accurate calculation significantly improved the stability of performance, which made it possible to place heat-resistant glass in the hopper area for partial release of infrared radiation towards the room. An improvised fireplace heats the room and serves as a spectacular decor element.

Rocket furnace from a profile tube

For a hike, equipping a summer cottage, solving other "temporary" problems, a mobile version of heating equipment is suitable. The Robinson oven can be used as a pertinent example. The fuel and air supply is organized through a profile element (rectangular section 150 x 100 mm). The combustion zone is made of a pipe. The divider at the outlet is used as a rack for warming dishes.

Other models

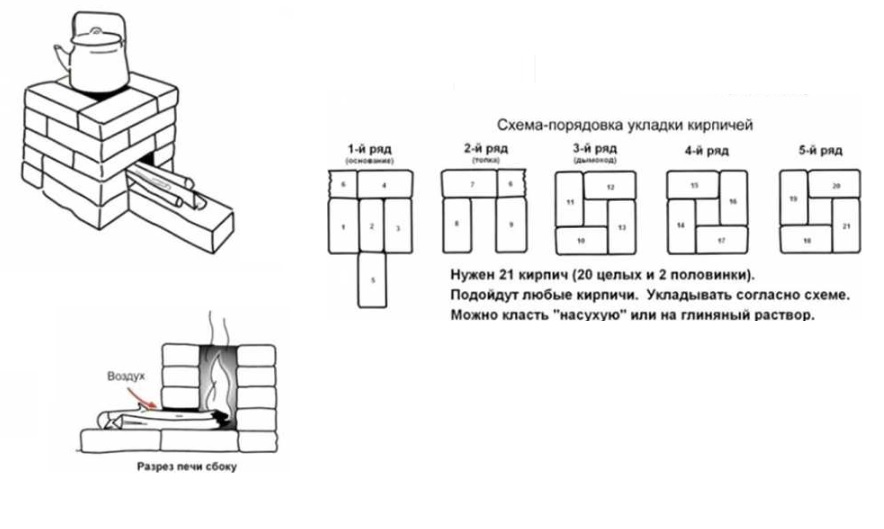

A functional do-it-yourself rocket furnace can be made from 20 whole bricks and two halves. Such a structure is assembled in literally ten minutes on a prepared flat site. Careful calculations and drawings are not needed. Working operations are carried out without welding equipment and building mixtures. Fuel consumption is approximately 3-6 times less than firewood in comparison with "potbelly stove". It is permissible to use damp firewood, branches, fragments of old furniture.

Unlike a campfire, this design retains heat for a long time. Cookware can be placed in the narrow opening. For convenience, a specialized support is used - a lattice made of steel rods or cast iron. Even in this simplest version, a high temperature is created in the working area, which contributes to the complete combustion of fuel with minimal smoke emission.

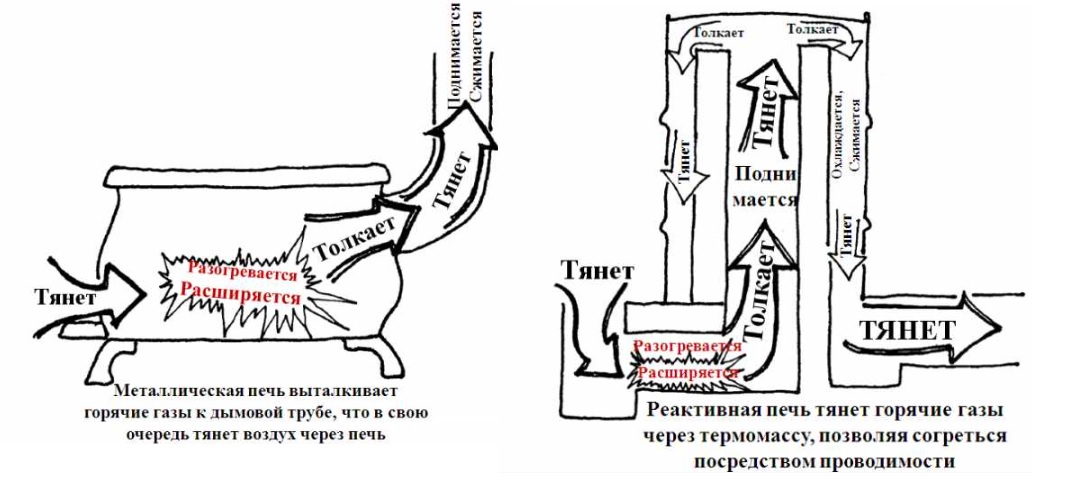

Principle of operation

An ordinary fire does not provide a rational use of fuel resources. A significant part of the energy is uselessly dissipated into the surrounding space. There are no convection processes, heat accumulators. Precise regulation of the combustion process is not possible. Oxygen access is unlimited.

With the use of a chimney and a closed working area, the noted disadvantages are eliminated. However, a jet furnace is more efficient than a typical "potbelly stove". The main difference is the chimney located inside the main structure. An increase in the gas escape path is accompanied by a gradual decrease in temperature in different areas (for example, the values are given in C °):

- central mine (riser): 700-1100;

- the gap between the walls: 250-380;

- area under the bed: 30-90.

The illustrations show design features that provide sufficient thrust while extending the fume extraction path. Another advantage is the high-temperature decomposition of organic matter with a limited supply of oxygen (pyrolysis).

If a do-it-yourself rocket oven is created correctly, favorable conditions are provided for the formation of low-molecular hydrocarbon compounds. Heating devices of this type are capable of providing an efficiency of more than 90%. Similar solutions are used in the design of household solid fuel boilers for long-term burning.

Homemade construction

In the absence of experience, you can choose a simplified design of several bricks, a bent pipe. If you have the skills to handle a welding machine, create a furnace from a square profile and sheet metal.

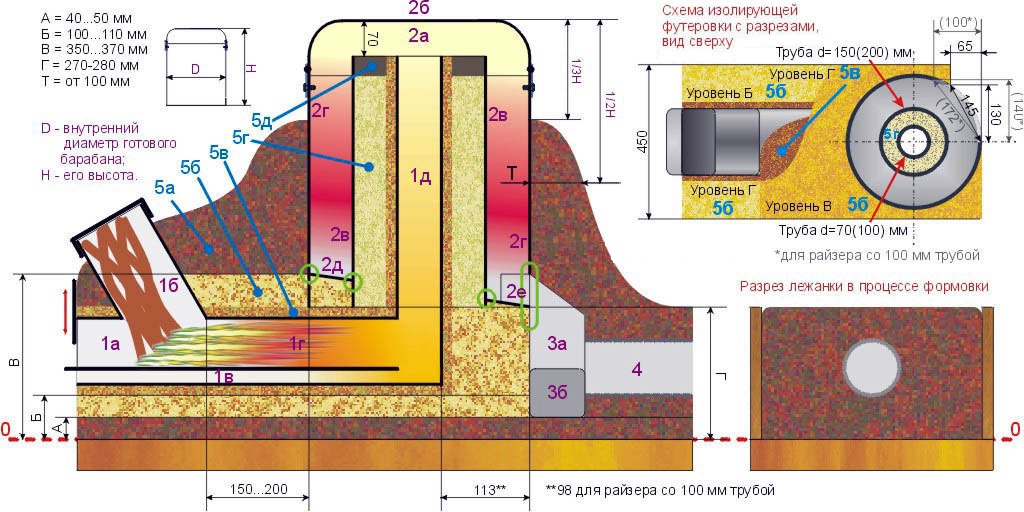

Furnace drawing and dimensions

The presented option can be adjusted taking into account the volume of the room, other personal requirements and preferences. The developers recommend setting the riser bore diameter between 65 and 105 mm. Resize the shell accordingly.

For storage of thermal energy, adobe was chosen. This material is not heat resistant, so the temperature must be reduced to a safe level. Additional recommendations:

- the drum can be made from a standard 50-liter cylinder;

- ensure perfect tightness of the smoke exhaust system to prevent the penetration of soot into the porous adobe;

- to remove the residues of mechanical impurities, a second ash pan is installed.

Step-by-step instruction

A do-it-yourself reactive wood-fired oven can be created according to the following algorithm:

- For the manufacture of a mixture of the main heat-insulating layer (5b), crushed stone from chamotte brand ShL is used.

- The support frame for the stove is assembled from wooden logs (100 x 100) with cells of no more than 600 mm, the distance under the lounger can be increased.

- For cladding, mineral cardboard, tongue-and-groove boards are used.

- Wooden blanks are pre-treated with impregnation with biocidal additives.

- The area under the main part of the structure is covered with a metal sheet.

- After placing the structure at the planned place, formwork is installed, adobe is poured.

- A drum is made of a gas cylinder of a suitable size.

- To create reliable welded joints, electrodes with a diameter of 2 mm, direct current with a strength of 60-70A are used.

- The sealing seal is created from an asbestos cord and fixed with heat-resistant glue.

- A riser is assembled from the prepared steel blanks.

- The lower layer of insulation is installed, plywood (20 mm) or boards are used for formwork.

- Filling with mortar is performed up to level B according to the drawing. It takes 1-2 days for this part to dry completely at room temperature.

- Install the firebox, controlling the accuracy of the vertical position.

- Part of the blower will protrude outward, therefore, at the final stage, the wall is leveled with adobe.

- After filling with the mixture to level G, it is recommended to accelerate drying with a conventional 60-75 W incandescent light bulb (placed under the riser).

- Install an ash pan made of steel sheet 0.8-1 mm thick.

- The drum tube is mounted with the formation in the inner part of the wedge-shaped slope towards the outlet (mixture 5b).

- A lining with layer-by-layer filling (5g) is created, the plug is made of clay.

- The assembly is continued according to the scheme, the corrugation, drum and ash pan covers are installed.

- After completion of drying (2-25 weeks), the formwork is removed, the surface is formed, the visible metal parts are painted.

Explanations for the composition of building mixtures (5):

- a - adobe made of clay and straw, the consistency of thick dough;

- b - clay of medium fat content with chamotte crushed stone;

- c - chamotte sand with clay in proportions one to one;

- d - river sand without washing with a fixed granule size (2.5-3 mm);

- e - furnace clay of medium fat content.

They purchase in advance the tools and consumables necessary to perform work operations. The list of purchases is made on the basis of the prepared project documentation.

How to heat a rocket stove

Taking into account the long path of the smoke exhaust system in a stationary structure, it is clear that it is necessary to start the operating mode after preheating. When working with "Robinson" and other compact analogs, this rule does not need to be followed. But a large furnace is first heated with dry shavings, paper, and other suitable consumables. For loading, a blower with an open door is used. The degree of readiness is assessed by the characteristic decay of the noise. At this stage, a normal fuel charge is used in the corresponding part of the furnace.

It is recommended to use the offset of the main hopper cover and the blower door to quickly adjust the operating mode. If there is too much oxygen, combustion is activated while blocking the pyrolysis process. In such conditions, fuel consumption indicators deteriorate, carbon deposits form in the riser. It should be emphasized that it is difficult to clean the closed central channel. In the worst situation, its throughput is reduced to critically small values.