Frame construction is rapidly gaining popularity due to a number of advantages: the reliability of structures, a budget mechanism and the strength of the structure. To make a residential building happy with heat, thermal insulation options are being considered, among which cross technology is used more often than others.

Parameters for choosing insulation

Before going to the store for building materials, it is important to determine some parameters. The first feature is the thickness of the walls. The regularity and length of stay in housing is analyzed:

- the country house assumes a short visit - 10 cm will be enough;

- a room divided into an apartment or a residential building is created as a permanent residence - the minimum value for a wall thickness is 15 cm.

The second defining characteristic is the type of energy used to heat a room during cold weather. The emphasis is on where you want to save. If you plan to install low-cost energy carriers, it is recommended to stay on compacted materials with a thickness of more than 20 cm. When expensive heating technologies are used, it is better to take a good fifteen-centimeter insulation.

Cross-insulation materials

Cross-sectional insulation (PU) of a frame house is a way to reduce heating costs. The level of costs is reduced by 4-5 times in comparison with other insulation options.

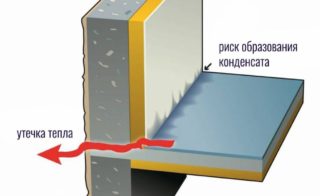

The main feature of PU is the absence of cold bridges, which makes it possible to stop the circulation of cold air flow inside.

The main material is a heat-insulating layer, the thickness of which is 15-25 centimeters. The thicker the insulation, the higher the percentage of resistance to extreme frost. However, not only this parameter affects the quality of the product. There are other requirements for heat-insulating raw materials:

- environmental friendliness;

- resistance to mechanical damage;

- high fire safety;

- low level of thermal conductivity;

- structural strength.

Various types of construction wool and sawdust meet these standards.

Mineral, basalt and ecowool

Minvata is used for thermal and sound insulation of buildings for various purposes: industrial, public and residential. It has undeniable advantages:

- low thermal conductivity;

- low density;

- high vapor permeability, which facilitates ventilation loads;

- operational period - 25-70 years;

- environmental friendliness.

However, there are disadvantages in using the described product. When exposed to water, cotton wool loses its insulating properties. During installation, due to the mineral wool, dust and microfiber are formed, which, if it enters the respiratory tract of a person, causes irritation.

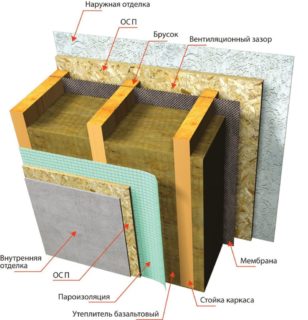

Basalt wool is a kind of mineral insulation. Interacting with moisture, the basalt is not impregnated with it, so the thermal insulation properties are preserved. Dust and micro-debris are also generated during operation. Therefore, it is necessary to use a respirator during repairs.

When laying ecowool, there is a need for expensive special equipment - a professional pneumatic device.When using this material, there is a risk of ignition, therefore it is not recommended to carry out insulation with ecowool near sources of fire, near chimneys and chimneys.

Sawdust

Sawdust - particles of recycled wood. Outwardly they resemble dust. The main advantages of raw materials:

- no harm to the external environment;

- relative cheapness;

- satisfactory level of heat-saving parameters.

When choosing sawdust as a heater, it is worth taking into account some points:

- To maintain heat, it is necessary to mix sawdust with gypsum or lime.

- The material should be treated with antiseptics and fire retardants.

- There is a risk of fire.

- There is no resistance to biological influences, attacks of rodents and pests.

Before insulating a house, you should consider in advance the layout of electrical wiring, ventilation ducts and fittings in order to avoid the formation of condensate and steam, take into account all fire safety requirements.

Technology advantages

If the frame is insulated with a cross method from the outside, a number of advantages can be noted:

- Transferring frame racks to a more suitable temperature regime. Cross-over insulation helps prevent water vapor condensation.

- Protecting the corners of the house from the effects of cold weather.

When it comes to internal insulation, other advantages stand out:

- Concealed electrical wiring.

- Possibility of mounting socket boxes and heating communications.

Thanks to some design parameters, it is possible to save on fasteners and perform the lathing, taking into account the dimensions of the sheets for the primary decoration.

Work order

The results of the work performed are influenced not only by the materials, but also by the installation scheme.

External insulation

Installation of PU is carried out in the standard way in the following stages:

- Bars 50 * 50 mm are placed horizontally in the direction from bottom to top. The step is 60 cm, however it is recommended to measure 59 cm.

- A five-centimeter layer of thermal insulation is placed in the formed spacer.

- A membrane is placed on top of the created structure, which works to protect against moisture and wind.

- Another windproof film is overlapped at a distance of 10-20 cm.

This arrangement gives access to the ventilation ducts and is convenient for the final interior coating.

Internal insulation

After external insulation, the master proceeds to processing the room from the inside. The works are carried out as follows:

- A layer of insulation of 5 cm fits between the jibs flush. The second layer completely covers the wooden frame.

- Installation of vapor barrier structures is in progress.

- A crate is installed to accommodate the last cover.

It is forbidden to push or tamp the insulation. The amount of air inside the cotton wool affects the thermal conductivity.

The attic floor, roof and roof are completely insulated according to the same scheme. In the case of a floor, an additional installation of a strapping bar with a windproof and thermal insulating membrane is required.

The effectiveness of cross-warming of a frame house

The effectiveness of the described design:

- Reduced material costs.

- Reducing the cost of heating the house by reducing the consumption of the fuel used.

- Creation of comfortable living conditions.

- Increased service life.

Cross-warming of frame structures is a progressive method. The method does not differ in a complex installation scheme and provides excellent heat and sound insulation performance.