To overcome the problem of uneven heating of premises, instead of traditional methods, a more progressive one is proposed - a plinth heating system. Now there is no need to install massive radiators under the windows, because they have been replaced by warm skirting boards, which are much easier to install. A skirting-type heating system with water or electric heat supply is a sure step towards home comfort. Consider how skirting heating devices are arranged.

The principle of operation of baseboard heating

The baseboard heating system is based on a special way of installing its constituent elements - at the bottom of the wall. Thus, it becomes possible to more efficiently distribute heat flows. Being installed around the entire perimeter of the room, baseboard heating convectors transfer heat not so much to the surrounding air, but directly to the walls, from which, in turn, the room air is heated. It is recommended to locate plinth heating radiators mainly along the outer walls, but they can be installed along the internal partitions as well.

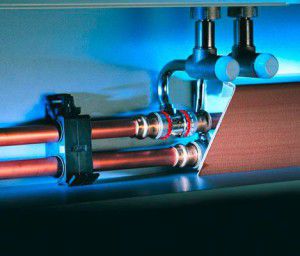

Heating devices are so compact that in their appearance they are almost indistinguishable from ordinary skirting boards. Inside each convector there are heat exchange modules, which, depending on the type of system, can be liquid or electric. The thermal conductivity of these heating devices is close to the maximum possible, since their structural elements are mostly made of copper and aluminum. It is enough to heat baseboard heating radiators only to a temperature of 40–45 ° С.

The bodies of the devices are equipped with two rows of slots: cold air enters through the lower ones, and heated air comes out through the upper ones. Plinth convectors for electric and liquid heating systems are installed close to the wall, and the heat, as it were, flows from bottom to top along the surface of the wall. As a result, judging by the reviews, plinth heating provides a more uniform heating of the room, compared to conventional radiators.

Two different concepts should not be confused: plinth heating pipes and plinth water heating. The first of them means one of the ways of supplying the coolant (from below) to a conventional radiator, and the second is a special type of heating system.

First, let's pay attention to the features of plinth piping in traditional hot water heating systems.

Plinth heating pipes

It is possible to lay pipelines from a water heating boiler to radiators in different ways: from above or below, openly along the wall or hiding in grooves. Alternatively, you can mount the heating pipes in a special box attached to the bottom of the wall. This method of semi-concealed installation is called plinth heating system wiring.To speed up installation work, manufacturers recommend purchasing ready-made sets of plinth wiring.

For example, the Simplex plinth heating pipe installation system consists of a set of all necessary elements, which includes straight parts and corners, connections and plugs. The outer, facing part of the box is an analogue of a conventional plastic skirting board, the color of which can be selected. The material used for this is resistant to constant exposure to high temperatures.

The basic part of the structure is fixed to the wall with several dowels. Installation of one-pipe and two-pipe versions of plinth distribution of heating pipes is carried out using adjustable holders. It is allowed to use pipes with a diameter of up to 22 mm. The design reliably holds the pipeline elements in a fixed position, and a removable decorative panel, if necessary, opens access for inspection and maintenance.

The range of the supplier of skirting systems for the installation of heating pipelines simplex includes wiring elements that are compatible with hard or soft types of flooring. We also offer boxes with the possibility of additional laying of low-current lines. The joints of the radiators with the baseboard wiring of the heating system can be covered with decorative panels of a special shape.

Now let's take an interest in the device of the plinth heating system: what varieties it is presented and what is it characterized by.

Advantages and disadvantages of baseboard heating

The main advantage of skirting convectors is their compactness. These heaters have a height of no more than 15 cm from the floor with a thickness of only 3 cm.

Other benefits should be listed:

- uniform heating of the room over its entire area and a stable air temperature both near the floor and under the ceiling;

- reliable protection of walls from dampness and, as a result, from mold and mildew, which is especially important for the structures of a wooden house;

- reduction of fuel consumption by 22% due to the fact that there is no need to pay for "extra" heat;

- less labor-intensive installation of baseboard equipment and the availability of repair;

- modern design that suits any interior style.

Studying the reviews about baseboard heating, one cannot fail to notice that this system also has disadvantages:

- high cost of purchased equipment and payment for installation work;

- the need to use a circulation pump in the system;

- difficulties in balancing the system according to the degree of heating of each of the convectors;

- the requirement that skirting heating radiators are not obstructed by pieces of furniture.

So that the heat transfer does not decrease, you need to make sure that the convectors located near the floor are not clogged with dust.

Installation of a system of warm skirting boards

When installing baseboard heating equipment, it must be borne in mind that the liquid and electrical versions of this system have fundamental differences.

Liquid (water) heating

Basically, a skirting convector for liquid heating systems consists of a heat exchanger and an outer casing. In order to increase the heat transfer area, the copper-aluminum heat exchanger is equipped with numerous transverse plates.

The list of necessary devices for an autonomous baseboard water heating system includes the following elements:

- boiler equipment using any type of fuel;

- heat carrier, most often water or non-freezing liquids;

- circulation pump providing forced movement of the coolant;

- collectors for the supply and return circuits;

- copper, metal-plastic or PVC pipelines for distributing the baseboard heating system;

- baseboard radiators that carry out heat exchange in rooms;

- thermostats, manometers.

The connection of the circuits of the skirting-type liquid heating system to the collector is carried out according to the beam scheme. Such a scheme is preferable when it is necessary to heat a large number of rooms on several floors. Thus, it is possible to ensure the efficiency of the skirting equipment and reduce heat loss.

To install a system of warm water skirting boards, you must:

- lay two pipes along the walls in the sections from the collector to the installation site of each of the radiators;

- in the selected place at the level of the wall and floor junction, install the back panel of the skirting convector for the liquid heating system from fasteners;

- connect the supply and return pipelines to the heat exchanger;

- hang the mounted radiator onto the rear panel mounting hooks;

- check the tightness of the connections;

- install an outdoor decorative panel;

- proceed with the pressure testing and balancing of the plinth heating system.

The coolant is poured into the system, while simultaneously releasing air from it with the help of devices specially designed for this. After full filling and a test run of the system, the areas where there is still air remains, and it is also removed.

In order for plastic pipes to serve longer in the baseboard heating system, the coolant should not be heated above 85 ° C, and the pressure should not exceed 3 atm.

Electric baseboard heating

An electric baseboard heating system is much easier to mount than a water one, because there is no need to lay pipelines supplying the coolant to the radiator. In this case, the main element of the heating device is a radiator unit with an electric heater. The heating element is built into the copper tube in the lower part of the radiator, and an electric cable covered with heat-resistant insulation passes through the upper tube.

Plinth electric heating convectors are powered from a conventional home electrical network. At the same time, the wiring must be able to withstand an increased load, because the estimated power consumption will be at least 200 W for each running meter of the heating system.

It is more convenient to lay a power cable for baseboard heating even at the stage of building a house. They make outputs at the points of connection of convectors and temperature sensors for electric baseboard heating, then the floors are poured and the walls are plastered. The elements of the warm plinth are installed after the completion of all finishing work. Heating devices are mounted along the walls, connected to the power supply and thermostats are regulated.

Despite the high degree of moisture protection, it is undesirable to install electric baseboard radiators in a bathhouse and other rooms with high humidity.

Placing heating elements at the bottom of the walls is becoming one of the most efficient heating methods. In most rooms where we spend a lot of time - in a cottage, apartment or office - plinth heating contributes to the creation of a surprisingly pleasant microclimate.

The video presentation will help to understand the convenience of creating an electric baseboard heating system in the house: