Mineral wool is a fibrous insulation made from molten rocks and slags. It is used as heat and sound insulation. The mineral slab is cheap, lightweight, practical, and efficient.

Advantages over other heaters

The heat-insulating qualities of the material are due to the fibrous structure. It is different: horizontal, vertically layered, spatial, corrugated. The structure increases the heat-saving properties of the insulation and determines its advantages:

- Low thermal conductivity - 0.044 W / m * K. Minvata is slightly inferior to expanded polystyrene and polystyrene, noticeably exceeds expanded clay and even more building materials.

- Mineral plate insulation does not burn and does not support fire, does not deform under the influence of high temperatures. It is used for insulation in rooms where flammable substances are stored.

- Mineral wool is resistant to any chemically aggressive substances. It does not lend itself to mold or mildew. Rodents avoid it too, especially glass wool.

- The material is used as an acoustic protective layer.

- Mineral wool in slabs, unlike many other heat insulators, practically does not shrink.

- The installation of the slabs is very simple. They are easy to install and attach to the surface.

- The material does not emit hazardous substances. It is used for thermal insulation of living quarters from the inside.

- Minvata serves up to 70 years, but this period is determined by the terms of use. If moisture penetrates the material, it quickly deteriorates. The exception is glass wool, which is insensitive to moisture.

Mineral stone wool slabs are the only insulation that can be used in wooden houses. It is vapor-permeable, does not accumulate moisture and prevents wood from rotting.

Main varieties

Depending on the source material used, there are 4 types of insulation: glass, basalt, slag and stone wool. If their thermal insulation properties are approximately the same, then the other characteristics are different.

Glass wool

For manufacturing, sand, dolomite waste and up to 80% of cullet are used. Raw materials are melted in a furnace and the finest glass filaments are obtained by blowing with steam. Their thickness is 5–15 microns, their length is 5 cm.

Glass wool is resistant to fire and water, its hygroscopicity is extremely low. Retains properties at temperatures from -60 to +500 C. The material is vibration-resistant.

Disadvantage - fragility of glass fibers. In this case, the finest glass dust appears, irritating the mucous membrane. Work is performed only in a respirator, goggles and protective clothing.

Stone wool

The source is a rock: diabase, gabbro. The fibers are thin - 5–12 microns, but their length is less than that of glass wool - 1.5 cm. It absorbs water poorly and is used for cladding wet rooms.

The material does not lose its quality up to +600 C. At high rates, stone wool melts. The thermal conductivity coefficient is slightly higher than that of glass wool. Its plus is crease resistance, which makes installation easier.

Basalt wool is similar in properties to stone wool, but blast-furnace slags are not used in the production of basalt mineral slabs. Its thermal conductivity is lower, the cost is slightly higher.

Slag wool

It is made only from the blast furnace slag melt. This is a cheap type of insulation. Slag wool is hygroscopic and cannot be used for pipeline thermal insulation.Retains residual acidity, therefore, upon contact with it, the metal is oxidized. It is not suitable for insulating the front door, frame buildings.

Specifications

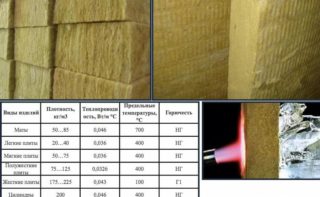

Thermal conductivity and resistance to temperature are the main characteristics of the insulation. These qualities depend on the material and density.

| Views | Density, kg / cubic meter | Thermal conductivity, W / m * С | Limiting temperatures, С | Flammability |

| Mats | 50 to 85 | 0,046 | 700 | Not flammable |

| Lightweight slabs | 20 to 40 | 0,036 | 400 | Not flammable |

| Soft | 50 to 75 | 0,036 | 400 | Not flammable |

| Semi-rigid | 75 to 125 | 0,0326 | 400 | Not flammable |

| Hard | 175 to 225 | 0,043 | 100 | 1 class |

| Cylinders | 200 | 0,046 | 400 | Not flammable |

| Loose cotton wool | 30 | 0,05 | 600 | Not flammable |

All other things being equal, a mineral semi-rigid basalt slab is the most effective option.

Any structures - vertical, horizontal, inclined - are thermally insulated with mineral wool during the construction of all types of structures. It is used to isolate industrial equipment - chemical, petrochemical, mechanical engineering, pipelines, oil and gas pipelines, tanks. The insulation is suitable for both outdoor and indoor use.

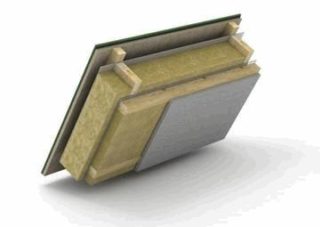

The material is included in building blocks such as sandwich panels, reinforced concrete or three-layer concrete blocks.

Density marking

The density indicator helps to quickly determine the purpose of the product. The marking includes a letter indicating the degree of hardness, and numbers - the density of the mineral wool. The following categories are distinguished:

- PM-40 and 50 - very soft, does not withstand the load. Suitable for insulating frame structures.

- P-60, 70, 80 - due to low density, the material is easily deformed, therefore it is used in lightly loaded structures: pitched roof, pipe thermal insulation.

- ПЖ-100, 120, 140 - mineral wool semi-rigid and rigid insulation is used for thermal insulation of walls, floors, roofs in low-rise buildings. It is part of panel structures.

- ППЖ-160, 180, 200 - withstands high loads. Suitable for insulation of flat roofs, concrete screeds, building facades.

- PT-220, 250, 300 is a rigid and solid heat insulator. They are used for finishing and insulating works in difficult areas: reinforcing screeds, insulation of ceilings.

The complete labeling contains more information. It indicates the dimensions of the product, the flammability class, the level of moisture absorption, the tensile strength.

Dimensional range of insulation boards

Dimensions of heat and sound insulating mineral wool slabs are regulated by GOST 9573-2012. The dimensions depend on the density of the material.

| Plate | Length, mm | Width, mm | Thickness, mm |

| PM-40.50 | 1000, 2000 | 400, 500, 600, 1000 | 30-200 |

| PP-60, 70, 80 | 1000, 2000 | 400, 500, 600, 1000 | 30-200 |

| PZh-100, 120, 140 | 500, 600, 1000, 2000 | 400, 500, 600, 1000 | 30-200 |

| PPZh-160, 180, 200 | 500, 600, 1000, 2000 | 400, 500, 600, 1000 | 20-200 |

| PT-200, 250, 300 | 500, 600, 1000, 2000 | 400, 500, 600, 1000 | 20-60 |

The sizes of products at the insistence of the customer can be changed. The thickness of the mineslabs is not increased, as it is unprofitable.

The list of the most famous and reliable manufacturers includes Technonikol, Rockwool, Knauf, Ursa, Izovol. In the ranking of the best in 2019, Rockwool takes 1st place. TechnoNIKOL is the most famous of the Russian manufacturers.