Wall-mounted gas heating boilers are a good budget option for private houses and apartments, since they do not cause problems during installation and operation. Despite the long service life, most units fail from time to time. Most often, the problem is the burner damping, but sometimes it is difficult to understand the cause of the malfunction. In most cases, the owner of the boiler is able to eliminate the malfunction on his own. It is worthwhile to study the most common causes of problems in advance and find out what can be done in each case.

Why the boiler does not turn on

After correct installation, in the absence of violations, a wall-mounted boiler usually does not cause problems to its owners. The average service life of the unit is from 4 to 9 years, but breakdowns can occur at any stage of operation. When the wall-mounted boiler does not turn on, an error message appears on its display with an indication of a personal code or number, depending on the specific model of the device.

You need to write it down and see the exact value in the instructions, where descriptions of the most common malfunctions are presented. The most common problem is the lack of ignition of the gas-air mixture. The flame may light up and go out after a while or be completely absent if the boiler closes the gas supply valve. This happens for a number of reasons:

- connection polarity problems or phasing error;

- oxidation or contamination of the ignition electrode, the presence of a gap in the burner;

- cracks or breakdowns in the insulating part of high-voltage wires;

- difficulties with connecting electricity;

- lack of gas supply due to a faulty meter or dirty filters;

- broken control board.

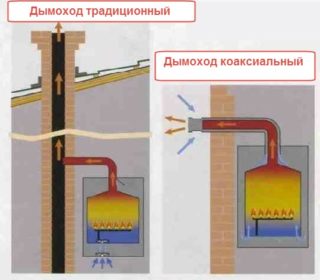

Lack of traction is another popular problem. In such a situation, the combustion products are not completely eliminated, the boiler for heating does not turn on and does not ignite. In addition, difficulties often arise with the water pressure, which normally should be at the minimum mark and be monitored by a personal sensor. Users can monitor the pressure level with a built-in mechanical or electronic type pressure gauge.

All gas boilers operate in a closed heating system, in which the pressure drops periodically. If it drops to a critical level of 0.5-0.7 bar, the device will not start, since the sensor registers the problem as a breakdown and suspends all operation of the device.

The boiler may not work in only one mode, for example, DHW or heating. In such a situation, the unit requires a full-fledged diagnosis from a specialist who will be able to accurately determine the cause of the breakdown.

Simple malfunctions can be eliminated at home on your own, in more complex cases it is better to entrust this work to a professional. According to safety rules, it is forbidden to independently change parts, turn off individual elements if the heating boiler does not ignite for unknown reasons.

How to solve the problem

If the boiler does not work, it is extremely important to begin with preventing potential accidents.To do this, the device is disconnected from the mains and the gas valve is completely shut off, then an initial visual inspection is carried out and the boiler is checked for blockages or mechanical damage. After a sudden shutdown, it is not recommended to ignite the unit immediately.

If there is an open combustion chamber, you need to light a match or a lighter and keep them as close as possible to the holes through which air enters the burner itself. When the draft is not very clogged, the tongue will begin to deflect towards the main holes, and the fire will continue to burn at an acceptable level. A weak deflection of the flame indicates a blockage.

A malfunction can be detected even at the stage of the boiler functioning: if it hums excessively, and the flame has no shade, then the draft is too powerful, it must be reduced.

When the gas boiler does not turn on at all and is not able to produce any flame, check the connection, the operability of the outlet and the integrity of the electrical wiring, since problems with the electrical network can become the cause of the malfunction. Clogged burner nozzles are also eliminated on their own. They are cleaned by detecting clogging by the color of the flame, which should normally be blue in color.

Often, the boiler does not function due to low pressure in the general gas pipeline network, so it is better to additionally find out information about a potential accident in the gas service.

Gas equipment is classified as a hazardous device. If the wick in a hot boiler suddenly goes out, the device does not heat up or cannot turn on even after several attempts, you need to take emergency measures. The device is completely turned off, the room is checked for gas contamination and it is thoroughly ventilated.

You can understand the severity of the problem after testing the thrust and studying the error number on the device screen.

For what reason the burner goes out

A burner is a metal part in the form of a tube with various nozzles through which gas enters, combusted in air, injected in a special chamber. When turned on and during operation, a mixture of carbon monoxide and carbon dioxide, as well as soot with water vapor, is generated. These combustion products are discharged to the outside. An even distribution of gas is achieved by a system of nozzles, air is injected using natural draft.

The fuel supply is shut off due to the automation of the device in such cases:

- draft decreases or completely disappears in the chimney;

- the gas pressure in the supply line falls below normal;

- the flame of the burner itself goes out due to the impossibility of removing the combustion products.

Automatic shutdown sometimes occurs due to external causes or due to generator breakdown. Owners of non-volatile devices of a simple design are less likely to encounter such problems. Modern wall-mounted boilers with a closed combustion chamber often turn off the fuel supply themselves in a number of situations. This happens when the flow sensor is triggered due to the stopping of the movement of the heat carrier in the heating system, the air supply is reduced or completely stopped.

Power surges and power outages in the home network can also cause problems with the boiler. If the unit has become worse in heating or does not work in one of the modes, you need to pay attention to such signals.

To prevent the boiler from shutting down during operation or at the wrong time, the device must be inspected more often for faults. It is better to trust this work to a specialist who can identify even complex problems at an early stage.

Other problems of gas boilers

Almost all wall-mounted boilers are equipped with a panel with a screen or indicators, as well as a control board. If there is no indication, make sure that the boiler is connected to an electricity source.The connection is checked with a multimeter at the place where the board is connected to the device. When there is no voltage, you can try to reconnect the device. In addition, pay attention to the place where the fuses are located. In standard units, they are located on the board itself or in the connection area.

If everything is in order with the fuses, the voltage in the control zones remains at around 220 volts, it is worth checking the control electronics and the gas generator. When the fuses are blown, test the operation of the pump, priority valve, fan, and instrument wiring for a short circuit. It is recommended to replace the blown fuses and check the boiler operation again. There are situations when parts burn out again immediately after replacement, then it is worth sequentially turning off the high-voltage sections of the boiler in order to identify problem areas.

The device board may fail after water ingress. This happens in the event of leaks and condensation inside the protective housing. Most often, water gets there through wires. Such damage cannot be repaired; on a failed board, there will be characteristic oxidations and stains. The broken part is replaced and the entire system is checked to prevent damage in the near future.

It is important to prevent problems in time and call specialists for a preventive check of the device several times a year.