Flow-through and storage boilers are equipped with residual current devices to protect against human electric shock and prevent breakdowns. When the home network is overloaded, wiring problems knock out the RCD on the water heater. The malfunction can be detected and corrected by yourself.

- Features of work, selection and connection of RCDs

- Safety device requirements

- Residual current device classification

- Household and power traction voltage

- By the number of poles

- By rated current

- Differential current

- Main and additional reasons for triggering

- Why does the RCD of Termex boilers work?

- Features of repair and replacement of RCD

- The nuances of repair work

Features of work, selection and connection of RCDs

The protection device is necessary to de-energize the power line in the presence of short circuits and current leaks. The device operates on the principle of comparing the parameters of the incoming and outgoing current. With a difference of 30 mA, the circuit is automatically opened. A person touching the body of the equipment cannot get an electrical injury.

Safety device requirements

The protective device for the water heater must meet the following criteria:

- Power. The indicator depends on the power rating of the home network and the number of phases.

- Power line voltage. Single-phase models are suitable for heaters connected to 220 V, three-phase - for 380 V.

- Degree of protection. Optimal models for an apartment - with shutdown at a leakage of 30 mA.

- Place of installation. Modifications marked C16 and C25 are suitable for an apartment boiler or a heater in a private house.

- Class. Class A RCDs are suitable for equipment with high energy consumption. AC class models often burn out.

The device is installed in a socket or switchboard. In the latter case, a three-core copper cable is used. Since the heater is a high power appliance, you will need to ground the outlet.

Residual current device classification

A high-quality device provides disconnection of consumers under voltage, controls the transmission of the rated current, de-energizes the circuit when there is a difference between the input and output currents. Manufacturers produce a wide range of devices with different characteristics, based on which they are divided into several types.

Household and power traction voltage

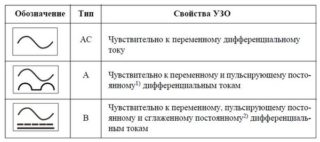

Depending on the conditions in which the RCD will work, you can select the types:

- AC - reacts to sudden or slowly increasing changes in alternating differential sinusoidal current.

- A - triggers with a sudden increase or slow increase in the parameters of alternating sinusoidal and pulsating constant differential currents.

- B - turns off when the alternating, rectified, direct current changes.

- S and G are selective devices equipped with an off-time delay mode.

Electromechanical models are not voltage-referenced. The signal for them is the differential current. Electronic options are powered from a power line or other source.

By the number of poles

Depending on the characteristics of the electrical network, you can choose an RCD:

- 2P, or bipolar. Suitable for single phase lines. Equipped with 4 paired terminals on each side for neutral and phase connection.

- 4P, or four-pole. Suitable for three-phase and single-phase networks. There are 3 phase terminals on each side of the apparatus and one for the neutral connection.

The RCD compares currents, so the number of poles must match the number of conductors.

By rated current

The indicator must be equal to or greater than the total rating of the switches for the groups. Modifications for 6000 A are suitable for domestic use, but if there is a new house and a transformer station, 10 kA RCDs are installed near the input.

Differential current

The devices that operate at a differential current of 30 mA will be optimal for the protection of humans and animals. Switches operating at currents from 100 mA are used for fire-fighting purposes - they completely de-energize the line.

The devices are mounted on the wall, on a DIN rail. There are devices that have the design of carriers, adapters, sockets.

Main and additional reasons for triggering

If the boiler knocks out the machine, the reasons are most often as follows:

- Damage to the insulation of electrical models with tubular heating elements. The protective layer is destroyed when water comes into contact with conductive nodes. To check the part, it will need to be removed from the tank and inspected. Cracks indicate that the heater needs to be replaced.

- Leakage current. They occur when the water heater is connected to old wiring, cable with bare cores, mechanical damage to the insulation and installation errors.

- Shorting the bare cable to the case. When the bare core contacts the case, the machine will be switched off permanently. The phenomenon leads to electric shock.

- Inconsistency of the RCD with the voltage and power parameters. Knocking out is periodic - the device simply cannot cope with the load.

- Malfunction of the device itself. The main reasons are the wear of the starting mechanism or the sinking of the test key.

Often the shutdown occurs after heating the water. The malfunction occurs in boilers with deformed bodies in contact with the phase.

Why does the RCD of Termex boilers work?

Water heaters Termeks flow-through and storage type are popular because of the ease of connection, tank capacity, good power and inexpensive cost. When an RCD is triggered during operation, it is possible that the Termeks water heater is damaged or the power supply is faulty:

- Breakdown of the case. If there is a ground connection, the device will work immediately.

- Broken wiring in the room. The neutral is most often damaged.

- Mechanical damage to the heating element. The heater coil is in contact with water in the presence of permanent scale.

- Contact of the body and phase. Shutdown occurs after heating the water.

- The ground line of the riser is thrown to the net zero. If the boiler starts up, there is a risk of injury.

- Malfunction of the RCD itself. Chinese complete instruments often fail. They need to be changed.

- Exceeding the load rating. When the boiler, stove and iron are turned on at the same time, protection against network overloads is activated.

Boilers are installed only with an earthing line.

Features of repair and replacement of RCD

If the machine knocks out when the boiler is turned on, there is a high probability of breakdown. You can repair a faulty RCD with experience, tools and parts. The optimal solution for the owners is to replace the device. To determine its likelihood, a monthly check is required. To do this, use the button to create an artificial leak.

The nuances of repair work

The complexity of the repair lies in the absence of a circuit. Therefore, when troubleshooting yourself, you should be guided by the following algorithm:

- Removal of sealant and self-tapping screws on the body.

- Removing the fasteners with a slotted screwdriver and disassembling the device.

- Making a circuit by sketching from a printed circuit board.

- Testing the device. The leakage current is simulated by applying a voltage from a resistor to the amplifier. A leak is indicated by the activation of the triac and a short circuit.

- Troubleshooting and assembly of the device.

It is necessary to connect the water heater in order to protect against leaks, overloads, short circuits through an RCD or an automatic device.

Knocking out the safety shutdown device for boilers occurs for several reasons. The breakage can be detected on your own. Since the RCD is not equipped with a circuit and is a complex device, it is easier to replace it than to repair it.

"The protection device is necessary to de-energize the power line in the presence of short circuits and current leaks." - RCD is not intended for short circuit protection! For protection against short-circuit, an AB (circuit breaker) must be installed in series with the RCD.

Yes, the RCD does not protect against short circuits. The difavtomat combines the functions of an RCD and a conventional machine.

As for the operation of the RCD in the water heater circuit, from our own experience, probably more than 95% of the failed heating elements are to blame.