Unlike solid fuel units, connecting an electric boiler is a problem that usually worries not only the owners of private buildings. You need to worry about choosing the type of equipment, its installation and integration into existing communications. One of the most preferable options is the installation of an electric boiler with connection to the mains and heating system.

Basic connection tasks

During installation and subsequent connection of the boiler to the existing mains, the following regulatory requirements must be observed:

- For inserting into the heating main (connecting to the power grid), a method is chosen that guarantees complete safety of equipment operation.

- The operations carried out should not violate the established mode of operation of communications and lead to a change in their scheme.

- It is important to select in advance the options for turning on the heating system, which will improve the efficiency of its operation.

Provided that these requirements are met, the main task of connecting the electric boiler to the 220 Volt power grid and the heating main can be considered solved.

Strapping features

In order to properly connect the electric boiler to the existing highways, you first need to deal with its strapping. It traditionally contains a number of additional elements and measuring instruments. With this in mind, it is important to determine in a timely manner the location of the boiler equipment as part of the heating system.

Choosing a location

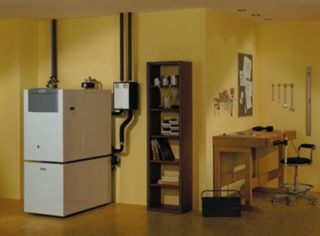

The current regulations do not provide for any restrictions on the place of installation of the electrical unit. It is selected taking into account the provisions of safety and serviceability. The boiler is installed in a private house, taking into account the following requirements:

- Floor-mounted equipment is housed in a separate room where the residents of the building have limited access.

- Wall-mounted models can be mounted in the kitchen or bathroom.

- If the unit body comes into contact with the wall, it will be necessary to put a heat-shielding lining made of asbestos or basalt under it.

When installing an electric boiler in a bathroom, difficulties arise with connecting to a 220 Volt network, since in this case a powerful power cable will need to be laid to it. These activities are associated with additional costs; funds will also be required to hide and decorate the laid communications.

Optional equipment

The requirements of the standards regulate the procedure for arranging the piping, each element of which is installed in a certain place:

- The safety group (GB) is installed behind the heating unit, since a maximum pressure develops here when the circulation is stopped.

- The expansion tank is installed taking into account the pressure in the circuit at a certain distance.

- The heating medium pump is located directly in front of the boiler, at the point of the circuit with the minimum temperature.

In modern electric boilers, the piping elements are usually already built into the structure itself.

Wiring

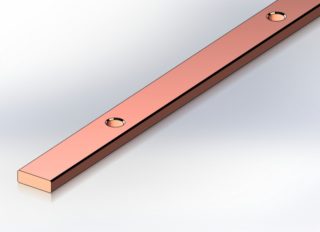

Before installing the product, you should take into account that to connect it, you will need electrical wiring based on a cable with copper conductors.The cross-section of the wires is selected in accordance with the value indicated in the equipment passport. The contact terminals are brought out in the form of a separate block located in the lower part of the case. There is also a copper bolt with a standard size M6, designed to connect the grounding bus.

When arranging grounding, it is important to ensure that the electrical contact at the attachment point is very reliable. To do this, the connection area should be thoroughly cleaned with sandpaper. Otherwise, electric shock protection will not work effectively.

Connection diagrams

When evaluating the schemes for connecting electric heating boilers to the water main, choose from the following options:

- the simplest scheme with forced circulation, in which an expansion tank, a pump, a safety valve and a Mayevsky device are provided;

- scheme without an expansion tank and a separate circulation pump;

- option with the use of a special parallel-connected capacitive buffer that accumulates heat at night with reduced tariffs.

Any electric boiler connection scheme, provided that it is installed correctly, guarantees the required heating efficiency.

Self-connecting the boiler to electricity will require the following recommendations:

- only devices with a power of up to 3.5 kW are connected to a regular outlet;

- power units with an indicator of up to 7 kW are connected directly to the switchboard;

- boiler equipment designed for 12 kW is commutated with a single-phase 220 volt network;

- units of higher power are included in a 3-phase 380 volt network.

For the installation of boiler equipment, you will need a VVG wire with three copper conductors (for a single-phase version), as well as an automatic switch and an RCD. The last two elements work together and provide line protection against overload and leakage currents up to 30 mA.

Installation steps

The installation and connection of elements of an electric boiler is carried out in several stages:

- The unit is installed on the floor or mounted on a wall at a height of approximately 1.5 meters.

- Outlets are connected to the pipelines with the simultaneous installation of ball valves.

- An expansion tank is mounted in the return line.

- In the same area, a fine mesh filter is mounted.

For ease of maintenance, an additional valve is installed in front of the device. In induction and electronic units, pumps are completely absent - they are mounted separately in the boiler piping. In such systems, the use of a security group is mandatory.