In homes where there is no gas or centralized heating, individual heating systems are used, including solid fuel and electric boilers or solar systems powered by solar energy. These systems have an important drawback - the uneven heating of the coolant due to the fundamental features of the functioning or the influence of external factors. They can be optimized using a heat accumulator for heating, which will act as a buffer between the heat source and consumers.

Purpose of the heat accumulator

The heat accumulator for various types of heating boilers is an impressively sized reservoir filled with water, which allows you to solve the problems that arise during the operation of a heating boiler:

- overconsumption of energy;

- excess heating power;

- overheating of water in the boiler;

- periodic fluctuations in the heating temperature due to the unevenness of the combustion process itself and untimely laying of firewood, coal;

- mismatch between the peaks of production and consumption of heat energy.

Some problems can be solved by installing a long-burning pyrolysis boiler, but in the latter case, it will not help. The peculiarity of the boiler operation is that after the fuel is loaded, the heat energy output gradually increases, reaching peak values, and then also gradually decreases. If you do not add fuel to the boiler in time, it stops, the coolant begins to cool down, and with this the temperature in the house drops. During peak heat production, the system is not able to efficiently distribute all the energy, since it is equipped with thermostats, so some of the heat is wasted. If the boiler is electric, it is much more profitable to accumulate heat at night, when electricity is calculated at a preferential night rate in order to consume as little electricity as possible during the day.

The heat storage tank for the heating system is made of stainless or ordinary steel, the inside can be coated with a protective varnish. The walls are painted from above with heat-resistant paint, then covered with heat-insulating material and leatherette. In fact, when a heat accumulator is connected, the volume of the heat carrier in the heating system increases, which makes it possible to compensate for the peak power of the boiler and at the same time to accumulate heat for transferring it to the heat carrier when the power of heat generation by the boiler drops. Thanks to high-quality insulation, the water in the heat accumulator cools down for a long time. It remains heated for several hours and even days and is pumped into the system by means of a pump. The principle of operation of the heat accumulator is based on the different heat capacity of various media, in particular water and air. A decrease in the temperature of 1 liter of water by one degree leads to an increase in the temperature of an air volume of 1 m3 by 4 degrees.

If, when using solid fuel and electric boilers, the installation of a heat accumulator is desirable, but not necessary, then the presence of a heat accumulator in the solar system is a necessary condition for functioning, since it is impossible to obtain solar energy in the evening and at night, and in autumn and winter on cloudy days, the use of the system is very limited.

Pros and cons

Pros of using a heat accumulator:

- Stores heat energy for hours and days.

- Overheating of the boiler is excluded.

- Thermal energy is not wasted, but accumulates in order to be used in the future, due to this, the efficiency of the boiler and the heating system as a whole increases.

- Allows you to save money.

- The air temperature in the premises is easily maintained at an optimal level, sudden temperature fluctuations are excluded.

- There is no need for frequent refueling.

- In addition to the solid fuel boiler, you can install a solar system, which is a free source of thermal energy.

- Some models of thermal accumulators for heating can combine the functions of a boiler.

Disadvantages of the system:

- Long heating - optimal installation in houses intended for permanent residence. In country cottages, which are visited in winter on weekends, such a device will not be useful.

- High cost - they cost about the same as a boiler, and sometimes more.

- Significant dimensions and weight - because of this, certain difficulties arise during transportation and installation. In addition, a heat accumulator intended for heating is installed in the immediate vicinity of the boiler, additional equipment must be located there, therefore, it is often necessary to allocate a special room for the installation of devices and prepare it in a special way: equip a support platform that can withstand the weight of the drive. When filled, the tank can weigh 3-4.

- A high-power boiler is required - the purchase of a storage device is justified if the boiler's power is not fully utilized, there is at least a double power reserve, otherwise the device will be idle.

When making a heat accumulator with your own hands, you will be able to save a significant amount. The simplest design is made of a stainless steel barrel or even a sheet of stainless steel with a thickness of at least 3 mm. You will also need a copper tube with a diameter of 3 cm and a length of 14 m. It is bent into a spiral and placed inside the tank. From below they make a supply of cold water, from above a tap for hot water, install stopcocks on the taps. It is imperative to insulate a self-made heat accumulator for a solid fuel boiler, otherwise it will be ineffective. It is also necessary to install pressure and temperature sensors.

If you cannot weld a cylindrical container, you can make a heat accumulator for heating in the shape of a parallelepiped - it is easier to make a reservoir of this shape with your own hands. The corners are additionally reinforced, from the outside they complement the structure with stiffeners - they are welded at a distance of 30-35 cm from each other. The ratio of the diameter and height of the device is 1: 3 (4).

Selection criteria

It is necessary to select a heat accumulator in accordance with accurate calculations, taking into account the parameters of the home heating system. However, in addition to the calculated values, the general characteristics of the heat storage devices are taken into account.

- Heating system pressure. According to this parameter, the heat accumulator must correspond to the heating system. In any case, the value can be higher, but not lower. What pressure the storage device can withstand depends on the wall thickness, the shape of the tank, and the material of manufacture. Heat storage systems for boilers with a capacity of more than 4 bar have a convex top and bottom cover.

- The volume of the buffer tank. This parameter is considered the most important and they try to choose a capacity of such a volume so that the drive can accumulate all the excess heat. But at the same time, an unnecessarily voluminous device is not needed.

- External dimensions and weight.The issues of transportation and placement of equipment will have to be resolved, therefore, everything must be carefully calculated: whether the tank will pass through the doorway, whether the overlaps will withstand when the tank is completely filled with water.

- Equipping with additional heat exchangers. They allow you to further optimize the functioning of the system. Models are selected according to the complexity of the entire system.

- Possibility of installing additional devices. Together with the battery clipboard, additional heating elements, sensors and temperature controllers are installed. If all elements of the system are selected correctly, fuel consumption can be halved.

The tanks are made of carbon steel or stainless steel. The latter are more expensive and last longer, and the former must have an anti-corrosion coating. You need to make sure of its quality.

Calculation of the volume of the buffer tank of the boiler

According to calculations, the heat accumulator should take all the energy from one fuel load into the boiler.

The volume of the buffer tank is usually calculated in such a way that during the combustion of one fuel load, the heat accumulator retains all the heat generated by the boiler. You can independently make only approximate calculations that do not take into account heat loss from heating radiators and the effect of air temperature in the room. The basic formula for calculating the volume of a heat accumulator:

W = k × m × s × Δtwhere

- W - excessive amount of heat;

- m - the mass of the liquid;

- from - heat capacity of the coolant;

- Δt - the number of degrees by which you need to heat the coolant;

- k - boiler efficiency.

From here you need to calculate the mass of the coolant:m = W / (k × s × Δt).

As W is defined as the difference between the values of the energy generated by the boiler and spent on heating the house; it is also necessary to clarify them and the time of burning the fuel fill. If the boiler power is given in the passport of the device, the heat energy consumption for heating must be calculated. The fuel burn-out time is determined empirically. Let's say it's 3 hours, but heating the house requires 10 kW / h. This means that in 3 hours it will be spent:10 × 3 = 30 kW.

Heat production by a 22 kW / h boiler is:22 × 3 = 66 kW.

Based on the calculation results, the excess heat will be:W = 66 - 30 = 36 kW. We translate into watts, we get 36,000 watts.

Using the formula m = W / (k × s × Δt), we determine the desired value of the mass of water. The efficiency is indicated in the passport as a percentage. This value must be converted to decimal by dividing by 100. For example, 80/100 = 0,8... The heat capacity of water is 4.19 kJ / kg × ° С or 1.164 W × h / kg × ° С or 1.16 kW / m³ × ° С.

Δt is determined by measuring the temperature of the supply and return pipe, subtracting the lower from the larger value. For example:Δt = 88 - 58 = 30 ° C.In this way,m = 36000 / (0.8 × 1.164 × 30) = 1 288.7 kg.

To store all the excess energy generated by the boiler, a container with a volume of at least 1,288.7 m3 will be required. The Jaspi GTV Teknik 1500 HP heat accumulator is suitable. With more modest calculation values, you can limit yourself to a tank, for example, 750 liters.

Diy connection methods and diagrams

The complexity and features of the connection depend on the type of heat storage device. Therefore, you should figure out what they are.

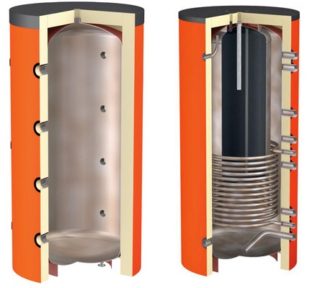

- The simplest design is an empty tank inside. The boiler and consumers are connected directly. The use is optimal if the same coolant is used in all circuits, the pressure in the system does not exceed the permissible values of the storage tank and the temperature of the coolant supplied from the boiler does not exceed the permissible values for the heating circuit. If the first two requirements are not met, when connecting to the system, you must use additional external heat exchangers. In the latter case, mixing assemblies with three-way valves should be installed.

- Buffer tank with an internal heat exchanger - one or more.The heat exchanger is a spiral tube made of copper or stainless steel. In such a storage medium, the coolant is mixed. The coil, located in the lower part, heats the coolant, hot water rushes upward as less dense. Another coil is located at the top, which takes energy and leads it to the heating circuits. A device of this type is optimal when using different types of heat carriers, at high pressure and temperature of the heat carrier, connecting several heat generators.

- A tank with a flow-through circuit for hot water supply. The heat exchanger is mostly located at the top of the tank. It must be made of metal that meets food water requirements. The circuits are connected directly. Such a system is preferable with a uniform flow of hot water.

- Heat accumulator with internal boiler. The storage tank stores heated water for domestic consumption. This type of heat accumulator can be easily integrated into open and closed heating systems equipped with solid fuel, electric boilers and solar collectors. Buffer tanks of this type are especially relevant when using electric boilers, when the coolant is heated at night and water is consumed during the day. A 150 liter boiler is enough for the daily water consumption of an average family.

There are several outlet pipes for the heat accumulator intended for the heating system, and they are located along the tank vertically, since there is a temperature gradient along the height. This is done in order to be able to connect circuits with different requirements for the temperature of the coolant, to reduce the load on the temperature controllers. As a result, thermal energy is used as efficiently as possible.

Other types of systems:

- The simplest strapping scheme, limiting the possibilities of adjustment. Hot water rises up and is taken from the upper point, after cooling down, it goes down and again enters the boiler. It is used when the pressure and temperature in the heat generator and heating circuits are the same. The temperature is controlled only by increasing / decreasing the heat carrier flow.

- The system contains mixing units, bypasses, therefore, a more accurate regulation of the coolant temperature is possible. Equipment efficiency is achieved by installing, for example, three-way valves.

- An additional tank is included in the system, so that a small amount of hot water is available immediately after starting the boiler. The consumer does not have to wait for the system to warm up completely, but the water supply is not large, and the system heats up more slowly than the classic one.

- Inside the buffer tank there is one coil, through which heat energy passes from the source, and already from the coil, the coolant in the heat storage is heated. Different heat transfer fluids are used in this type of system. You can choose those that cannot be mixed due to incompatibility of chemical characteristics. Through the coil, you can supply heating or hot water supply, or the coolant from the source will circulate through this circle.

- An additional external heat exchanger is installed in the system. It allows you to maintain the desired temperature in the battery.

- System with a flowing hot water circuit. It is optimal if the hot water is used evenly. Otherwise, it is recommended to purchase an energy storage device with a built-in boiler.

- Single coil system with connection to an alternative energy source such as a solar collector. It is called bivalent. The connection is carried out in such a way that the collector plays a leading role in heating the system, and the boiler is connected when there is not enough heat energy.

- Multivalent system, where the main heating is carried out by low temperature sources, such as a solar collector and a ground source heat pump. They are connected at the bottom of the heat accumulator. A high-temperature boiler is used as an auxiliary source of thermal energy.

In the presence of various heating circuits and sources of thermal energy, a complex branched system is formed with many additional regulation equipment, sensors, safety groups. It is recommended to entrust its design to professionals, as high-precision calculations will be required.

Accumulator strapping for heat

The container must be well insulated. If it is a commercially available heat storage, the thickness and quality of the external insulation must be assessed. The better and thicker the heat insulator, the longer the heat will remain. Due to the special structure of the heat insulator, the heat accumulator works like a thermos. The thickness of thermal insulation in high-quality models is about 10 cm. It covers the body painted with heat-resistant paint. On top of the thermal insulation is a layer of leatherette. Insulation is carried out on its own in the same way. First, the tank is painted with paint that is resistant to high temperatures, then it is insulated with basalt wool with a thickness of at least 150 mm, and the top is covered with foil.