Often in country houses and dachas where there is no centralized gas, an autonomous system is used, in which a solid fuel boiler is the source of heat. This equipment has many advantages, but it also has disadvantages, for example, uneven heat production during combustion and the need for frequent refueling of fuel. An optional accessory can be used to make heating efficient. A buffer tank for a solid fuel boiler is a unit that accumulates excess thermal energy and releases them when it cools. Structurally, the device is a water tank with a coil and a heat-insulating layer.

Purpose of the buffer tank

The main task of the heat accumulator is to save energy in the heating system. Other tasks that the device solves:

- Simultaneous connection of several heat sources.

- Saving solid fuel up to 45-50% of the original amount.

- Heating stabilization, reducing the risk of overheating of metal components.

- Protection against cooling of the room, automation of heating, which is especially important if the owner leaves the house for a long time and does not want the building to freeze.

- Increasing the service life of a solid fuel boiler.

- There is no need for frequent replenishment of fuel, the interval between throwing wood or coal into the furnace increases.

The use of a buffer makes the autonomous heating system safer. Solid fuel will be able to completely burn in the furnace, the amount of soot deposits is reduced, and equipment needs to be serviced less often.

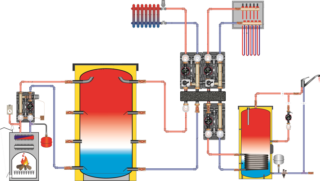

Using the heat accumulator

The buffer tank for heating allows you to adjust the thermal regime, preventing the atmospheric temperature from dropping to too low values. The efficiency of heating with a solid fuel boiler decreases as wood or coal burns; when a new portion of fuel is added, on the contrary, the amount of heat generated increases sharply. The buffer tank takes on excess energy, transferring heat to the system in a metered amount. In some cases, the heat exchanger additionally works as a water gun, in the most advanced designs it is used to provide hot water supply.

As a rule, the transfer of thermal energy from the buffer occurs at night, when the residents are sleeping, and not throwing firewood or coal into the furnace. This allows you to heat the premises of the house for as long as possible, so it will not be cold in the rooms in the morning. In some cases, a buffer tank is also installed in systems where the heat source is an electric boiler: this increases the level of fire safety.

Specificity of the buffer tank operation

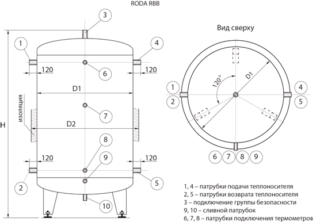

Structurally, the heat exchanger consists of several elements, each of which performs a separate function:

- Stainless steel spiral. This component is installed in models that are connected to heating systems with different heat carriers used simultaneously (solar collectors, pumps, etc.).

- Capacity.The tank is made of sheet metal, the surfaces are enameled, in some models the walls are made of stainless steel, so they are not subject to corrosion. The energy efficiency of the structure, the duration of the operation of the structure itself, depends on the volume. From the tank there are branch pipes, with the help of which the heat exchanger is connected to the boiler.

- A coil for hot water supply is included in the scheme of most modern buffer tanks.

The device is equipped with an inspection window used for equipment repair. The specialist will be able to determine in time that it is time for the technician to clean, and will quickly perform scheduled or emergency maintenance.

Advantages and disadvantages

The use of a buffer has many positive qualities:

- Increased reliability, protection of heating equipment from overheating, which can provoke a fire or explosion.

- Increasing the boiler efficiency, maximizing the efficient use of energy generated during fuel combustion.

- A relatively simple principle of operation, due to which the equipment has a long service life, rarely requires maintenance and repair.

- Smooth temperature control, maintaining optimal microclimatic conditions in the premises for 7-9 hours.

- The ability to connect to the water supply system, no need to install a separate water heater for the bathroom or kitchen.

- Minimizing human effort for boiler room maintenance.

- The ability to connect several heat sources, competent distribution of heating in several rooms.

Installing a buffer also has a number of disadvantages that must be taken into account when calculating equipment and purchasing a device. The container weighs a lot and is large enough, freight transport is required for transportation, and installation requires a large area and room height. Another problem is the increased inertia of the boiler equipment: the rooms will take a long time to warm up, which is especially unpleasant when the house is heated after the end of the winter season. Another drawback is the increased price of the heat exchanger itself: the amount may turn out to be more than the cost of the solid fuel boiler itself.

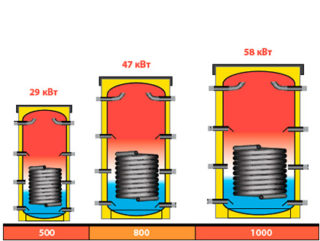

Calculation of the volume of the heat accumulator

Before buying a device, you need to correctly calculate the volume of the tank. The standard formula isQ = c × m × (T1-T2), wherein:

- Q - the total amount of energy expended;

- c - indicator of specific heat capacity;

- m - mass of the coolant;

- under indicators T1-T2 understand the temperature difference.

The result obtained needs to be adjusted taking into account additional nuances, including the presence of auxiliary sources, the quality of insulation, the area of the house, etc. If difficulties arise with the calculations, you need to contact specialists who will study the drawing of the heating system and determine the volume, taking into account all factors.

Model selection

To select a container, you need to pay attention to the maximum pressure, the material for the manufacture of internal elements, the possibility of connecting heating elements for backup heating, the quality of thermal insulation.

The finished structure must meet safety, energy efficiency and serviceability criteria.

When buying, it is advisable to prefer models offered by trusted manufacturers, since in this case the risk of quality problems is minimal.