The room can be heated with batteries, convectors, or the entire floor surface can be turned into an energy source. In the latter case, the homeowner gains additional comfort from the touch of the feet on the heated surface. The price of pleasure is the arrangement of a more complex system. In order for everything to work correctly, the technology of laying the warm floor must be observed. It has its own characteristics for each type of such heating.

Underfloor heating options

Depending on the tasks set, you can lay the heater over the entire area of the room or locally, only in those areas where there will be direct contact with it. There are three known options for arranging a home with a heating system of this type:

- water method according to the principle of steam heating;

- electric heating cable;

- infrared film.

Most often, in apartments and houses, heating elements are mounted in the base of those rooms where ceramic tiles are supposed to be laid - in bathrooms, kitchens and dining rooms.

Floor heating with water pipes

The system is a contour that is poured with a concrete screed. The basis for a warm water floor is a layer of thermal insulation. The pipes are located here in parallel at a certain distance from each other over the entire area. Due to the operation of the circulation pump, the heat carrier moves in the heater, which is previously heated in the boiler. The concrete surface is in contact with the flooring and the air in the room - this is how the room is heated.

Elements that are included in the heating system:

- boiler - gas, electric or solid fuel;

- coolant supply pipe;

- circulating pump;

- a distribution unit, which has a manifold that allows you to configure each branch of the circuit and a mixer;

- heater pipe;

- return line.

A water-heated floor is called conditionally; a special antifreeze can be used as a liquid.

Electric cord in the role of underfloor heating

Heating in this way is based on laying a special heating cable of a resistive type in the thickness of a cement screed or adhesive for ceramic tiles. The heating cores of the wire are equipped with a special end sleeve for connection to the network. The heater can be used as the main source of energy or in tandem with others.

The electrical heating system is a circuit similar to the liquid (according to the principle of location), which is mounted in the base of the room. The power and pitch of the cord is influenced by the type of finish and the depth of the wire. A properly organized circuit should warm up the house well and evenly.

Quality cord manufacturers adhere to the following European standards: EN 60811-506, EN 60335-2-96, EN 60335-1, IEC 60800.

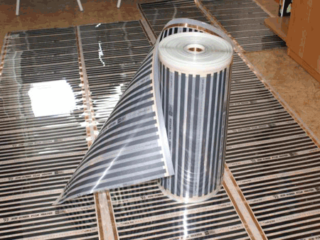

Film infrared underfloor

It is a film consisting of two layers, inside of which there is a sputtering of a heating element of carbon material.The film thickness reaches only 0.5 millimeters. This makes it possible to lay it without changing the height of the room. Electricity is supplied from the heater to the network by means of copper foil.

A running meter of film already has a certain power, so there is no need to measure the distance between the heaters - they are stacked end-to-end to each other. If you want to create more or less thermal effect, this is achieved by choosing the appropriate power of the substrate.

The advantage of infrared heating film is that it can be laid on any horizontal and vertical surfaces.

Strengths and weaknesses of the heating method

The system provides the following benefits:

- Increased level of comfort, including tactile touch.

- The heater temperature is relatively low in relation to the temperature of the radiators and convectors.

- Concealed installation that does not require the involvement of any additional decorating materials.

- The ability to use thermostats with wide functionality.

- The average length of service reaches fifty years.

The disadvantages of this type of heating include:

- The complexity of the organization of installation with the need to raise the base of the room.

- Not every type of topcoat can be used in such a system.

- Heating has an inertial nature and can bring the room into normal temperature conditions within 5 hours.

- People suffering from leg diseases, especially varicose problems, are not recommended to stay in a room with this type of heating for a long time.

- Heating synthetic materials leads to the evaporation of harmful substances.

A large heating area strongly dries the air and requires the use of devices for maintaining humidity.

Comparative analysis

The water floor has the most complex type of construction and is characterized by the high labor intensity of its organization. There may be bans on the installation of such heating in multi-storey buildings due to the danger of coolant flowing from the upper floors to the lower ones. In terms of energy efficiency, it can be more profitable than electric and its service life is also higher.

An electrical heating circuit based on a resistive cord has a simplified installation type and does not require strict horizontal laying, like a liquid one. The installation costs are also lower, and can be covered with tile adhesive almost at the surface of the floor covering. The service life of an electric heater is less than that of a liquid heater, and it creates magnetic waves that are harmful to humans.

The infrared emitter outperforms the previous two options for simplicity and low installation costs. It can be placed directly under tiles, laminate or linoleum. In terms of energy efficiency, it is 60% more practical than a heating cord coil.

Installation technology and features of the water floor device

Considering the pie that makes up the water heater, the following layers can be distinguished:

- In the lower part there is a layer of insulation with a thickness of 5 to 20 cm, depending on which floor the room is on.

- Next comes a special polyethylene film, on it a dimensional mesh for ease of installation - its thickness is approximately 4 mm.

- A pipe is attached from above, which is poured from above with a coupler.

- A damper tape up to 20 cm high should go around the perimeter of the entire pie room.

When laying underfloor heating using technology, the following points should be taken into account:

- The contour elements must be aligned in the horizontal plane strictly according to the level. This will minimize the risk of air pockets forming inside.

- Each individual circuit is recommended to be made in one piece, avoiding pipe joints under the concrete.

- Before filling the heater with a solution, the line is pressurized - filled with water heated to the operating temperature, and the pressure is increased. During the day, observe that there are no leaks.

- The screed is poured when the system is filled with water and its temperature is within 25 degrees. This helps to stabilize the pipe and evenly cure the screed.

- The object can be used no earlier than 30 days from the moment the concrete hardens.

The pipe should lie from the screed surface at a depth of 5 centimeters - this is a condition for the correct operation of the thermal circuit.

Electric floor heating technology

After rough work in the room - applying plaster to the walls, filling the ceiling and pouring the screed - you can start organizing heating based on a heating cord. Stages of work:

- The base of the floor is freed from foreign objects, dust and debris.

- A heat-insulating layer of expanded polystyrene with a thickness of 3 to 10 cm is laid on top of the concrete, depending on whether the underground space is heated or not.

- In a convenient place on the wall, a temperature regulator is mounted at a distance of about or above 30 cm above the finished floor surface, a temperature sensor is connected to it, which is placed on the floor at least 50 cm from the wall with a thermostat.

- A heating cord on a mesh base is laid out over the area, avoiding places where plumbing and furniture will be located in the future.

- The cable is connected to the thermostat.

- A screed is poured on top.

The laying of the infrared emitter is carried out with the difference that it is permissible to place the film under furniture and plumbing fixtures and there is no need to cover it with a layer of concrete, you can immediately install the floor covering.