Different types of heaters are used to heat private houses. Among such devices, there are hearth furnaces that do not have an ash pan. In them, firewood is stacked on the grate or bottom. The main field of application is bakeries and restaurants, but they can also be used for heating premises.

Furnace design

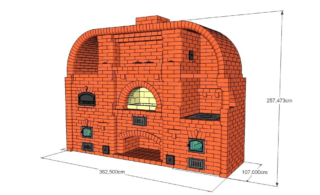

The heater consists of several elements, each of which has a specific function.

- Convection chamber. In the upper part there are valves and shutters.

- Housing. Steel or chamotte is chosen as the material.

- Forward stroke valve. It is used to direct smoke into the chimney.

- Main firebox.

- Side fire chambers.

- Refractory part. For this, fireclay bricks are used.

- Under.

- Reinforced wall.

- Fireclay brick in combustion chamber No. 4.

- Combustion chamber No. 4.

- Chimney hole.

Each model is equipped with a steel or cast iron door. In the center, a heat-resistant window can be made to monitor the flame.

Devices designed for food preparation include grids and burners for placing dishes.

Operating principle

The hearth furnace works differently from the classic one. The main property of such products is high efficiency with minimal fuel consumption. The burnout is distributed evenly. Due to the air entering through the door of the firebox, sufficient oxidation of the wood occurs, increasing the quality of their combustion and the level of heat generation.

Firewood is laid on the lower level in the loading chamber. Then the combustion process takes place in the working area. Gases are removed from the upper level and heat exchange takes place.

To maintain high temperatures (about 400 ° C), the furnace body is made of polished stainless steel. The lining is made of fireclay bricks or other fire-resistant material.

Varieties of hearth furnaces

According to the purpose, the ovens with underfloor heating can be divided into kitchen and heating ovens. For fuel - gas, electric, wood. According to the material, brick and metal devices are distinguished.

Kitchen

Kitchen ovens are used for cooking - baking bread or making pastries. Differs in miniature and simplicity. Can be installed in a private house. Restaurant models are large in size and have various additional functions.

Heating

Used for space heating. They do not have separate areas for kitchen trays and furniture. They are distinguished by a high level of safety and environmental friendliness. In Europe, it is the deck ovens that are approved for indoor installation.

Gas

The body houses the burner and annular tubes. Their number can reach 19 pieces. Kitchen models have 2-5 tiers for installing baking trays, the temperature is regulated on each floor. You can work with such a product around the clock.

Electrical

Outwardly, they practically do not differ from models powered by gas. All the differences are inside. Instead of a gas burner, there is a heating element in the electrical device. Kitchen appliances can also have 2-5 independent temperature controlled chambers.

From the point of view of operational safety and ease of use, it is more profitable to buy electric ovens.Moreover, gas is a more economical fuel.

Wood burning

Classic wood stoves have been in use for decades. They add coziness to the house, during the burning process, a pleasant aroma of wood is heard. Wood is one of the most affordable types of fuel, so such devices are often installed in country houses. The disadvantages include the complexity of handling. It is necessary to put firewood on your own and watch it burn out. The condition of the fuel must also be monitored. The tree should not be wet. Great attention is paid to the choice of the breed.

Metallic

Metal products are made from cast iron or steel alloy. The positive qualities include ease of installation and maintenance. During operation, the case becomes very hot, so you cannot touch it. The service life is about 50 years. Such models do not tolerate temperature extremes, which can lead to cracks.

Brick

Brick appliances are distinguished by good heat accumulation and the duration of its release. Externally, they look stylish and complement the interior. The service life reaches 100 years. Disadvantages - high cost, complexity of self-installation. The hearth brick oven must be installed by a professional.

Advantages and disadvantages

Deck ovens for home heating and cooking have positive and negative qualities. The advantages include:

- The possibility of installing several tiers in the oven for the kitchen and adjusting the temperature of each section. This allows you to cook many dishes at the same time.

- Fast heating of a large area.

- The ability to create a hearth oven with your own hands. The order, diagrams and drawings are presented on the Internet.

- Environmental friendliness. The stove does not pollute the atmosphere with smoke. Minimal carbon dioxide emissions.

- Ease of operation. Difficulty can only arise in handling wood fuels.

- Durability.

- High efficiency reaching 82%. The stove can burn for a long time (about 10 kg of firewood burns out in 12 hours).

- Safety. The home stove is distinguished by good fire safety, subject to the conditions of use.

Disadvantages:

- Only one heat source can be used in a design.

- The impossibility of burning coal, peat and other types of fuel.

- The complexity of laying a brick model. A call of a specialist is required, which requires additional financial costs.

Each of the varieties of hearth furnaces has its own pros, cons and features. Compared to classic stoves, they are safer and more sealed, but the efficiency is 3-5% lower. Therefore, the choice between a hearth and a grate furnace is made taking into account the requirements for the device.

Selection recommendations

Deck ovens for home heating are selected based on their location. It is necessary to calculate in advance what dimensions the device should have. You also need to ensure that the chimney pipe is at least 1 meter in length. An equally important indicator is power. The higher it is, the better the oven heats up. But a powerful device will require more fuel.

Popular residential models:

- Fireplace stoves WGO. Produced in Germany and made from HBO + refractory chamotte.

- ECO + oven. It has a simple design and low cost. Made of refractory materials.

To heat non-residential premises (bathhouse, garage), you also need to select a model in terms of power and size. Outwardly, such hearth bath stoves look less attractive, but their cost is lower. It is recommended to take furnaces of the KIV, PKO-40 series. They are able to heat the room to the required level without serious fuel costs.

Features of use

The oven is easy to operate. To warm up the product, you need to do the following:

- Load pallets into a wood-burning stove.Gas and electric models are connected to the gas supply and the mains, respectively.

- Dry the heating element after inactivity in an electric oven. The rest of the types can be turned on immediately.

- Select the desired program mode.

- Preheat the chimney for 6-7 minutes.

- Check the thermostat readings. The temperature is automatically maintained in most modern models.

If the oven is used for cooking, you need to open the lid and immerse the sheets with kitchen utensils into the chamber. After the end, the device turns off. It should not be kept in working order for more than an hour.