The designs of solid fuel heaters are constantly changing and improving. New parts are being installed, assemblies and mechanisms are added, which makes it possible to achieve greater productivity and efficiency of thermal devices. The grate for the stove is the part that cannot be dispensed with in any design, regardless of its type and size. The product can be purchased in the retail network or, having the tools and skills, you can make it yourself.

Varieties of grates for the oven

Despite its narrow functionality, stove grates differ in several ways. The raw material for the manufacture of parts is iron with a certain carbon content, which makes it resistant to high temperatures. The most common is cast iron, less often heat-resistant steel alloys are used.

Since solid fuels have different designs, shapes and sizes, ash pans for a furnace are characterized by a variety of manufacturing options.

The following categories of products can be distinguished:

- Whole. They are monolithic parts obtained by forging or casting. It is impossible to disassemble them, there is only the possibility of precise adjustment to a specific installation site.

- Typesetting. The presence of locking joints on the parts makes it possible to assemble a grate of the desired shape and size for almost any firebox.

- Immobile. Once installed in the combustion chamber, they occupy a fixed position that cannot be changed if circumstances require it.

- Movable. Products can change position in the space for cleaning, some models have the function of adjusting the width of the gaps between the bars.

Thanks to a wide range of grates for the stove, you can complete any type of boiler - for home and summer cottages, direct and long burning.

The main functions of grate bars

Any boiler is a structure where each part performs a specific task, ensuring the smooth operation of the entire device as a whole.

The grates in the oven perform the following functions:

- Fuel placement - coal, firewood, briquettes, other combustible items. Air enters through the blower, providing the oxygen necessary for the thermal reaction.

- Ash and ash removal. As the loaded material burns out, it turns into a powder and spills down through the grates. The fuel settles on the surface of the metal, and the flow of oxygen to it improves. Free space for loading the next portion of fuel.

The efficiency of the boiler depends on the design of the grates, the correct choice of metal for its manufacture ensures the durability of the device.

Selection recommendations

When choosing a grate for a boiler, it is necessary to take into account what type of fuel will be used in operation. Cast iron grates for the stove have different dimensions, but the main criterion is the size of the miscalculation in the grate. It determines the size of the waste that will fall out of the furnace through them.

Recommended clearance:

- for coal - 30x300 mm or 28x205 mm;

- for firewood and briquettes - 140x115 mm or 330x250 mm.

The optimal ratio of the area of the gaps and gratings is 1: 1.Deviations in one direction or another lead to a decrease in the efficiency of the device.

Cast iron is more resistant to heat, but brittle, it is better to use it under coal. Alloy products cannot be broken, but they can melt from excessive heat. The optimal solution for them is the use of briquettes and firewood.

Specifications

Depending on the type of fuel used and the design of the boiler, the grates are made of monolithic parts or hollow pipes. The latest models are air-cooled, which reduces the likelihood of metal melting. The shape and size correspond to the firebox of the appliance and the configuration of the door through which they must pass during the installation process.

The following types of grates can be installed in ovens:

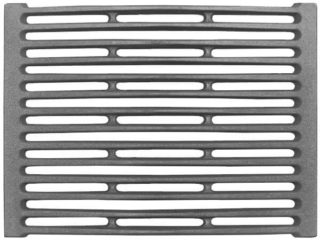

- Tiled. They are a rectangular product with parallel crossbars. They are universal, as they differ in different intervals for all types of fuel.

- Basket. Volumetric configuration products that are efficient but difficult to maintain.

- Beam. They are type-setting parts from which you can assemble grates of any size and configuration. They are used in the independent manufacture of the boiler for the assembly of non-standard gratings.

The correct choice of grate is as important as the chimney, damper and blower. In the manufacture of a boiler, every detail is important.

Installing the grate in the oven

It is not difficult to install the grates in the oven, but this process has its own nuances that must be taken into account:

- Metal expands when heated. On each side, there must be a gap of at least 5 mm to the walls of the boiler.

- The ledge for laying the grate should be made 10-12 cm below the edge of the door so that the coals do not fall out of the furnace when fully loaded.

- The grate should not be embedded in the firebox, as this is fraught with its deformation. To prevent the product from moving on the stops, it is better to put coarse sand in the cracks.

In order not to injure your hands, you need to put the lattice in construction gloves.

DIY grate making

To make grates for the stove with your own hands, you will need the following tools and materials:

- welding machine;

- Bulgarian;

- square;

- roulette;

- clamps;

- core.

As a material for manufacturing, you can use reinforcement or a corner. Both options are equally effective, but in the case of a corner it will be difficult to clean the indentations.

The grating assembly technique is the same for all types of rolled steel:

- Carry out measurements, draw up a diagram taking into account the openings for thermal deformation.

- Make stops. After stripping the metal, weld them to the inner walls of the firebox.

- Saw out the sides of the grate. Then cut the bars to the desired length.

- If the firebox has a circular or oval cross-section, bend the segments to fill the openings.

- Secure the sidewalls and crossbars with clamps. Weld the parts together.

It remains to install the finished grate in place and conduct a control firebox. If you plan to use all available types of fuel, it is advisable to make replaceable grates for coal and wood.

Popular models

The most popular models of grates that are on sale:

- RX PISLA;

- NTT;

- CROC;

- Impex Group.

These products are characterized by resistance to high temperatures and corrosion, strength and durability.

Well done !!!