Models of double-circuit gas boilers work reliably and save fuel, so the owners of private houses are trying to include a gas boiler in the heating and water heating system. The first launch is important for smooth operation in the future, therefore, special attention is paid to this stage. Preparation is carried out, the system is filled with a coolant, air is removed, then pressure testing and flushing are carried out.

Pre-launch activities

The position of the boiler is selected according to safety standards, away from fire hazardous objects. The distance to the wall structures is prescribed in the manufacturer's instructions. The casing of the unit is set taking into account the horizontal and vertical level, since the operation is disturbed when the unit is skewed.

The equipment is connected to the water supply and gas mains, ball valves and filters are installed using nozzles. Before lighting the boiler, lay the power supply and put a separate socket. Pre-connect the chimney pipe, check for the presence of draft.

Rules for filling the system with water

The boiler is disconnected from electricity before filling the system with cold water. The body has a tap located next to the fluid supply pipe. Special sensors monitor the pressure in the system. The coolant supply stops when the pressure gauge shows a pressure of 1.5 - 2 atmospheres.

The operating pressure values when starting the boiler differ slightly from different manufacturers. Additional water make-up of the system is required after removing air locks. Older models may not have built-in sensors, so they are purchased and installed separately.

Removing air pockets

The system will not be able to turn on or will function irrationally if the air accumulations in the circuit are not removed. Modern gas boilers have an automatic venting device. The reset system does not always work effectively, therefore manual intervention is required.

The accumulations are removed from the circulation pump, heating unit and radiators. The batteries are equipped with Mayevsky taps, which are placed in the open position, a container for collecting water is placed under them. A whistling sound means air is escaping, and the appearance of liquid means cleaning.

After removing the air, the arrow of the manometer should show a certain pressure, if necessary, make up the system.

Accompanying work when starting a gas boiler

Power is supplied, the heating regulator is set to the desired position. The appearance of a hum indicates the start of the pump. Using a screwdriver, slightly unscrew the lid before water begins to seep out, then the cap returns to its original position. This is done several times until the gurgling sounds disappear.

The electric ignition of the boiler is triggered and it turns on. The pressure in the system is regulated by the addition of a heating medium. The system with the circuits gradually heats up and enters the operating mode. The efficiency of the work depends on the accuracy of the preparatory stages.

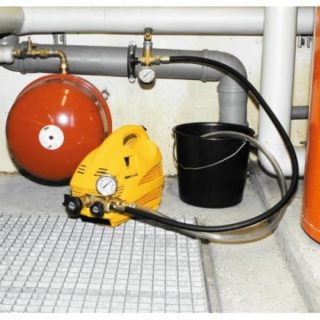

Crimping

The procedure is carried out to identify leaks. Liquid or air is pumped into the system and a ten-minute break is made, then the manometer readings are checked. Unchanged values indicate the tightness of the circuits and connections.

Sometimes pressure testing is neglected, for example, due to the lack of a pump, but carelessness threatens to stop the supply of heat in the middle of winter. The repeated procedure is carried out after the end of the heating season in preparation for the next one.

Washing

The process is designed to clean up debris from the system. The taps on all radiators are opened, and containers are placed under them to collect water. A pressure of 4 bar is established in the system, the flow of liquid washes the pipes and batteries from contamination. In advanced cases, the procedure is carried out several times.

There are 3 cleaning methods:

- Mechanical. Scale from the radiator is removed with a vacuum cleaner, scraper, brush after soaking the elements in cleaning solutions.

- Chemical. Acidic solutions are pumped into the booster and run for several hours. The method removes carbonate and ferruginous layers well.

- Hydrodynamic. Liquid injection under pressure.

For external treatment, use means to combat carbon deposits and soot. The use of household cleaning products is allowed.

Turning on the gas boiler

It is possible to ignite the gas boiler after commissioning by a special service. The called worker checks the compliance with the installation standards, the efficiency of the hood, and conducts a test run.

Turning on semi-automatic boilers is done by turning the regulator to the extreme position and pressing the wheel to start gas supply. Piezo ignition is performed by holding in this position for 10 seconds.

Floor

The flow of gas into the system is turned on when the inlet valve is opened. The impeller is moved to the ignition position.

Next steps:

- By pressing the handle, a forced feed to the ignition burner is ensured.

- After the appearance of a flame in the hearth, the handle is released.

- The control lever is moved to number 2 against the clock hand to ignite the main burner.

- The knob is placed in the position on the digit that corresponds to the selected temperature.

A temperature reading is written next to the numbers, which corresponds to the position of the regulator. Actions are repeated when the fire is extinguished.

Wall

Before starting the boiler, the device is connected to the outlet and the gas valve on the riser is unscrewed. The start button is pressed and the heating temperature is set using the keys on the control panel. For ease of labeling, there are pros and cons next to the buttons.

The electronic burner will turn on automatically when switching to hot water supply. Initial start-up may not occur if air has accumulated in the circuits. To get rid of it, the "restart" button is pressed. The mode is set using the remote control if remote operation is provided.

Features of turning on the old boiler

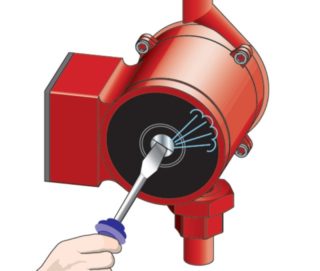

The start of the circulation pump requires attention, in which the blades are slowed down due to the air lock. The panel displays the corresponding failure.

Fixing the problem:

- the front cover is removable;

- the bolt is unscrewed in the center;

- a slotted screwdriver turns the shaft in the direction of the arrow;

- the brightly colored air vent cover rises and the air is vented.

The bubbling sounds will gradually disappear as the plugs will go through the expander valve. The pressure in the gauge is checked regularly.

Features of switching on boilers from different companies

Before turning on the Lemax boiler, you need to make sure that there is a coolant inside the system. The indicator is checked and the optimal operating mode is selected.The number of automatic devices and the power of the unit affect the formation of the regulations. Some models are equipped with traction sensors, which facilitates activation and control of operation.

Before starting the Navien boiler, an emergency temperature control device, a power control device, a fuse and a thermometer are additionally purchased and installed. Some models have these elements, it all depends on the configuration.

Starting a gas boiler in winter

The water for filling the system is heated up to + 20 ° С. The drain valves are closed, the air vents are placed in the open position until liquid appears from them. After that, the bleed valves are closed for a while, then the procedure is repeated.

Pressure testing is carried out after supplying the coolant to pipes and radiators to detect leaks. Changes in the operation of the system are monitored by the readings of the pressure gauge.