The modern market has a wide variety of devices that can be used to heat a private house. Nevertheless, brick ovens for wood-fired homes do not lose demand due to their versatility, relative ease of maintenance and a cozy feeling of living warmth. When choosing a design, you need to decide what functions it will perform and how compatible its installation is with the internal structure of the house.

Varieties of brick wood-burning stoves

There are several of the most common types of ovens. They differ in structural features, dimensions and functionality.

Dutch stove

The design of the Dutch woman is characterized by vertical placement of channels, the walls are thinner than other varieties. Due to this, the walls of the room are quickly heated by hot smoke. The fuel does not burn, but smolders slowly inside. Due to the long burning time, the need to load a new portion of wood is less frequent. Long breaks between fireboxes do not lead to a decrease in power. For successful operation, the oven must be regularly cleaned of ash deposits and soot. Anyone who serves a Dutch woman must be able to kindle: the view must be kept closed, otherwise the walls will soon cool down.

The unit has small horizontal dimensions (for example, models with a meter width and length are often found), while it can be of different heights. Small size makes this brick wood-burning stove suitable for summer cottages. She will be able to heat a room up to 70 m2. A tall structure running through the ceiling slab can serve a two-story house.

The Dutch woman can be equipped with additional devices - a hob, an oven or a tank for heating liquid. Such a multifunctional installation is suitable for a country house in an area where there is no electricity, also acting as a stove and allowing you to cook steam and baked dishes, dry vegetables, mushrooms, berries. At the same time, it is better to install a small stone stove in the bath.

Russian stove

The largest option. The design has an open firebox, which is blocked from time to time with a damper. In terms of its versatility, this oven is not inferior to the Dutch oven and can be used for preparing hot dishes, baking bakery products, drying berries, vegetables, fruits and mushrooms. In addition, you can dry your shoes on the stove, some models are equipped with a stove bench. When used in summer for cooking, you need to open a special channel that communicates with the chimney. The smoke masses are directed along it to the street. The stove can be painted or decorated with tiles. Not all materials are compatible with a unit that maintains a high temperature.

The main disadvantage of this option is its bulky and massive construction. The construction requires a solid foundation and large volumes of materials. Also, the stove needs regular kindling and cleaning of the passages.If you do not heat the unit for a long time during the cold season, condensed moisture will begin to settle on the walls due to the temperature jump. Repeated absorption of this liquid by a brick does not at all lead to an improvement in its performance. Such material is prone to crumbling.

Due to the high consumption of resources, the Russian stove is suitable for owners of private houses of permanent residence. For use in the country, it is better to choose a more compact model.

Swedish oven

Compared to the Dutch woman, the Swede has a better efficiency indicator and uses fuel more efficiently, but she will not be able to completely heat a two-story house. Its design is designed to serve two adjacent rooms. Additional equipment will be required to heat the rest of the premises. This oven is also suitable for giving.

The internal device has a system of several moves. The principle of operation is also similar to the bell-type models, when the flue gases burn out under the combustion chamber. The design of the furnace unit ensures good floor heating. The Swede can be equipped with a fireplace, oven, hob, compartment for drying things. The disadvantages include the need for materials of increased fire resistance for the manufacture of some parts (because of this, construction will be more expensive) and thermal insulation equipment that prevents heat loss in the lower part.

Scope of use

According to the criterion of the prevailing functionality, the aggregates are divided into several types. In addition to heating brick wood-burning stoves for home, cooking and cooking-heating are produced. Some models, in addition to these functions, are equipped with a fireplace, a tank for heating water or a contour unit for heating a larger area.

Models for strictly brewing purposes are usually used for summer cottages, to which the owners come mainly in the warm season. Putting it in a gas or electricity-fueled residential building can save on more expensive basic fuel. Usually, such devices have an oven and a hob, sometimes they are equipped with a container for heating liquid.

Units that combine the functions of heating the house and cooking food can be used in a permanent home and in the country. Depending on the power of the stove and the dimensions of the room, it can be used as the only source of heating or be combined with others.

The heating stove in the house or in the bath is not equipped with an oven and hobs. Some models have a fireplace and water heating option. If placed correctly, the stove will be able to serve two or three rooms.

Advantages and disadvantages

An attractive option for brick aggregates is the ability to accumulate heat and slowly release it to the air and walls while maintaining a comfortable temperature indicator. With regular heating during the cold season, the house is kept dry and warm.

Also, the advantages of brick ovens are:

- attractive appearance;

- ventilation of the room due to stove draft;

- the ability to cook food, dry vegetable products, bake bread;

- a bed, as well as the option of drying things (for some models);

- providing a source of fire when required.

As a minus, it is necessary to designate the inability of one unit to completely heat a large house. In this situation, it will be necessary to purchase additional heating equipment, for example, electrical appliances or a small stone stove, to be placed in rooms to which little heat reaches.

Choosing a place to install the oven

In a small dwelling, it is better to install the unit in the central zone so that its walls have a connection with several rooms and a kitchen at once. With this arrangement, a Russian stove can work for 3-4 rooms. If a more compact model is used, it can be mounted so that the hob and oven elements go out into the kitchen, and the back panel is built into the wall of one of the rooms, preferably closer to the border with the other.

Special care should be taken when installing stoves in wooden buildings. Since the material is highly flammable, building codes must be strictly followed to minimize the likelihood of fire or other unpleasant incidents. Also, when choosing a site, it is important to ensure that all parts of the structure are accessible so that there are no problems during cleaning and maintenance.

Materials and tools for work

Mandatory tools

First of all, the craftsman will need to prepare the sledgehammers in order to punch holes and split the brick blocks. Pick hammers are also useful for crushing and cutting pieces of material.

In addition, the following tools are required:

- trowel for coating surfaces with clay or concrete mortar and removing excess mixture;

- joints for the design of seams and sealing grease;

- shovel for solution preparation;

- devices for compaction of soil.

They work with jointing while the solution has not yet frozen; in the process, the instrument is constantly washed. To check the spatial parameters, you will need to purchase a square, a building level, a centimeter, metal and wood rules.

Necessary materials

The main material used is red brick with high fire resistance. Since it is tough, delivery should not be accompanied by shaking and other mechanical influences that could render it unusable. Fireclay brick is required for laying the firebox. The required number of elements is calculated based on the structure of the selected model. The solution is kneaded from clay - ordinary or with additives that provide high refractoriness.

For the construction, a number of cast iron elements will be required: a grate, firebox doors, cleaning section and blower, hob and latches. These parts are attached to a steel wire frame. If the scheme provides for the presence of a water heater, the corresponding container is prepared in advance.

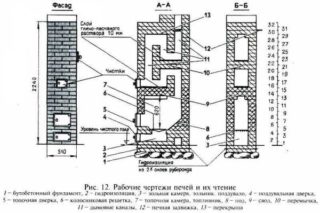

Instructions for building a stove with your own hands

First, you need to equip a dirt area for a stove. It is strengthened with crushed stone and then tamped. A little sand is poured on top, reinforced and formwork is placed.

In the future, the step-by-step work algorithm will look like this:

- If the stove foundation was not made during the construction of the house, prepare it. A concrete composition is poured into the formwork and leveled. If the walls are made of wood, insulating material must be placed over them to prevent the spread of fire. For this role, stainless steel sheets, natural stone, asbestos, fire resistant plasterboard products can be used. It is important that the material does not release substances harmful to health at high temperatures. When the concrete hardens, a roofing sheet is laid on top to protect it from moisture.

- The brick is laid in rows in accordance with the diagram describing the selected structure. In the absence of experience in this type of work, you can lay out half of the oven for training without using a solution, and only then proceed to the "finishing" operation. The evenness of the configuration in the process is measured out with level and corners. Laying bricks relies on the corner, the first of them closes the joints of the previous row.It is recommended to smear the solution thinly and tamp thoroughly.

- When you need to lay a row where the grate and the blower door are mounted, they should be reinforced with wire. A similar operation is done when installing the furnace door and grate. The niche behind the grate of the firebox is filled with solution. It should not be forgotten that the firebox is made of fireclay or silicate bricks.

- If the design implies the presence of a hob, you must carefully monitor when working with which next it is mounted. It must be placed on a metal corner welded into the frame. The dimensions must correspond to those of the panel.

- Another task is to timely install the oven cleaning door and water tank. The latter is placed on steel strips.

- The smoke pipe can be made of stainless steel or the same brick that was used for the main structure. Its dimensions must correspond to those of the chimney hole equipped with a valve. Formwork is placed around and concrete is poured into it. A sheet of metal is nailed to the surface of the ceiling made of wood, through which the pipe goes. If a transition is made between floors, it is necessary to overlay the pipe structure with a material that provides fire safety (usually mineral wool) and then lead it to the attic and then to the roof.

At the end of these works, the oven is subject to passive drying for a week. In this case, all latches and doors must be open. Then, during the week, active drying with dry wood is carried out every day. The first procedure is carried out with 2 kg of fuel, the second and all subsequent procedures - with 3-3.5 kg. At the same time, all doors are left open, except for the firebox. The process is considered complete when condensed moisture ceases to appear on the doors a few hours after the procedure. Then you can load the stove with additional wood. If cracks appear in the structure after a few months, they must be repaired.

A wood-burning stove will provide warmth and comfort in the house, will help in cooking and drying clothes. For high-quality work, the structure must be cleaned regularly. With a chimney, this operation is performed at least once a year.