When building furnaces, you need to use a special clay-based composition. So that the seams do not crack, and the stove or fireplace does not fall apart, it is important to select and mix the correct clay for masonry and coating the stove.

Varieties of clay for the oven

The quality of the composition is determined by the fat content of the base. According to this criterion, clay is divided into three types.

- Oily is the most plastic. However, when it dries, it cracks and greatly decreases in volume, due to which the furnace structures are deformed and destroyed.

- Medium fat is the best option. Dries with moderate shrinkage, does not crack. Possesses good adhesion, strength, heat resistance, hygroscopicity.

- Skinny clay has the lowest adhesion rates. It is dryish, quickly becomes covered with cracks, which leads to scattering of the masonry.

Finding quality material is a great success. Good clayey layers are found at a depth of five meters. The upper layers have a high content of sandy impurities and humus. This type is not suitable for ovens.

Main components

The clay composition differs depending on the added components:

- clay-sandy;

- clay-cement;

- clay-limestone.

Stove makers usually choose the first option. Fractional proportions depend on which clay to use for the oven. If it is oily, the ratio of sand will be 2: 1, if it is medium fat - 1: 1. Also, with good quality clay, you can do without additives.

If you don't want to measure out the components, you can take a ready-made composition. A 20 kg bag of clay-chamotte kaolin refractory mixture "Terracotta" costs 250-300 rubles on average.

Methods for removing impurities

The first step is to remove impurities from the natural clay stored for oven laying. There are different ways to do this.

Dry punching

The most primitive way. Use your hands to select everything that is superfluous - grass, pebbles, debris, grind large lumps. After that, the plastic material needs to be rubbed through a metal sieve with cells of about 3 mm.

The method can be made slightly less laborious by drying the clay. To do this, clay lumps are laid out on a wooden canvas and dried in the sun. In winter, this is done in the cold, laying it under a canopy so that it does not get covered with snow. With a small amount of material, they are placed indoors, on a heated stove or on a heating radiator. The speed of drying depends on the size of the lumps: the smaller they are, the sooner they dry.

Pour the dried clay into a box with thick walls and grind with a rammer. After grinding, clay dust is sieved through a sieve with fine meshes to remove various inclusions from it: pebbles, chips, and other debris.

Soaking and soaking

"Dry punching" is a rather laborious task, therefore it is more expedient to soak the clay after manual cleaning for 2-3 days.

- Place the material in a large basin in 12-15 cm layers, wetting abundantly.

- Pour in water at an approximate ratio of one to four to the clay.

- When the mass is soft, mix with a concrete mixer or other means.

- Wipe through the wire mesh 2–2.5 mm.

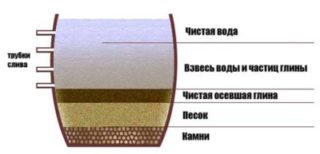

Soaking - soaking of sand-rich clay, in which it gets rid of impurities, becomes more plastic, fatter. To do this, place the clay mass in a bucket, pour in water in a ratio of one to three, leave overnight. Stir thoroughly in the morning until smooth. Let the composition settle. As soon as light water appears at the top, it must be carefully drained using a rubber hose.

There is also an older way of torturing:

- Several holes are drilled vertically in a wooden container with a small distance between them.

- Each of them, before filling the tub with a liquid clay mass, is muffled with a wooden stopper.

- Grains of sand and a variety of small stones precipitate first due to their greater weight.

- Subsequently, after settling, clay particles settle to the bottom.

- The upper layer of water gradually becomes lighter, but you need to wait until the liquid becomes transparent. As soon as the border of the clarified moisture drops slightly below the first hole from the top, remove the plug. The settled water flows out of the container.

- After the appearance of the next level of settled liquid, take out the next plug.

This process is repeated until all clarified water is completely drained. To speed up the precipitation after loading the solution into the tub, you will need to add bitter Epsom salts - about one pinch per bucket. If there is no wooden barrel at hand, it can be successfully replaced by a metal container suitable in height and volume. The principle of operation is the same with one difference - first, short lengths of pipes are soldered into the holes, and plugs are installed in them.

When all the settled liquid is drained, the liquid clay is transferred to a wide box and left in the sun to evaporate excess moisture. After the dried material ceases to be fluid, stir it periodically with a shovel. As soon as the mass becomes similar in texture to thick dough and stops sticking to the palms, it is covered with polyethylene or oilcloth and stored until the start of the oven work.

Proportions and mixing of the solution

In addition to cleaning before mixing, the clay for laying the stove must be prepared. The material is laid out in a box or barrel upholstered with metal, filled with water so that the liquid covers it entirely. If there are large lumps, they need to be broken into smaller pieces in advance. Everything is mixed well and left for a couple of days. The clay is aged for at least five days with the constant addition of water. After that, the solution must be mixed again and poured through a sieve into another container.

The clay composition should be of a pasty consistency, without impurities. If, after 48 hours, small lumps are found in the mass, it must be mixed again, broken all seals and kept for another day.

After preparation, you can start preparing the solution. If clay is mixed with sand, the latter is poured into a prepared container, then plastic material is laid out, and a sand layer is again poured over it. A shovel is used to mix the components. If moisture appears at the top, add a little sand. Topping up with water is required in an overly dry composition. The solution can be considered ready if it slowly slides off the shovel and becomes uniform.

If the base is medium fat, you do not need to add the sand component. Step-by-step instructions for breeding clay without sand for the stove with your own hands:

- The material is laid out on a wooden platform in layers, each layer is moistened.

- Upon reaching a height of 30–35 cm, the mass is mixed. For this purpose, you need to spank the upper layer with the back of the shovel.

- The kneading continues until a homogeneous substance is formed.

You can check whether the masonry clay for the stove has been prepared correctly as follows: apply a thin layer on the red brick, put another block on top and leave it for an hour or two. If, when lifting the upper brick, the lower one does not fall off, you can use the composition for the construction of the stove. The clay sets for a long time, you can immediately mix the required amount of binder. It will take about 20 liters to lay out a 50-brick stove for a bath, and to build a Russian stove 15-20 percent more.

When erecting a heating unit, you will need not only clay for laying stoves, but also a special plaster for coating the walls. You can make a simple clay mortar, but it is better to mix the plastic material with lime, or add a sandy, cement component. The procedure for making such compositions is almost similar to kneading a masonry mixture.

How to dilute clay for oven putty:

- The dry base is ground and soaked.

- Sand with lime or cement is introduced. Proportions of medium-fat clay with sand and lime 1: 2: 1. When including cement powder, it is necessary to proceed from the amount of the sand component in a ratio of 1: 3.

- To make the plaster layer stronger, you can add asbestos, fiberglass, hemp or straw in a 1: 2: 0.1 ratio (clay / sand / additives).

When additional ingredients are included in the clay solution, they are first mixed with each other, and only then with the previously soaked clay.

Checking the quality of the solution

The first test is carried out before preparing the clay for the brickwork of the oven. In order for the solution to come out of high quality, it is necessary to accurately identify the fat content of the clay. It will depend on this, what additional components are required.

How greasy oven clay is revealed as follows:

- A small amount of clay - about 1 kg - is thoroughly cleaned using one of the methods described and soaked for several days.

- The resulting mass is divided into five identical parts. Nothing is added to the first, the second is mixed with 25 percent sifted sand, the third with 50 percent, the fourth with 75 percent and the fifth with 100 percent.

- Each of the parts is kneaded separately. If necessary, add a little water until a pasty texture is achieved. You can determine the readiness of the solution with your hands. If it does not stick, the mixture is considered ready.

- The resulting material is checked for ductility. Each of the five particles is rolled into a small ball and flattened into a cake. All the resulting samples are marked with labels, which indicate the proportions of sand, and sent to dry. It will take 2-3 days for the fragments to dry.

- The resulting samples are tested. The cake should not be cracked or shattered when compressed. If you drop it on the floor, it should remain intact. Based on the results of such testing, the correct proportion of sand and clay components is revealed.

You can test for fat content and plasticity in another way. Roll into balls about 3 cm in diameter, placing each ball between two carefully rounded boards. Gently, smoothly press on the upper one, check the condition of the ball. If it cracks immediately, the composition lacks fat content. If cracks occur at half compression, the mixture is too greasy. With the correct proportion of the components, most of the specimen will flatten but not collapse.

Additionally, kiln clay is tested before the actual use. Better to redo the mortar than waste time building a stove that will crumble. To check, the composition is scooped up by hand and rubbed with fingers. A good quality binder should be slippery and oily. Experienced stove-makers detect the readiness of the composition by ear when mixing. Correctly made mixture "whispers" - makes a kind of rustling sound, and lags behind the shovel.You can also dip the trowel into the mixture, pull it out, and then turn it over. If a thick layer sticks, the composition is too oily, it must be diluted with sand. If the layer of solution falls off, there is an excess of sand, you need to add pure clay.

Clay mortar can be stored for quite a long time if no cement powder has been added to it. If the finished mixture is covered with oilcloth or polyethylene and placed under a canopy, it can be used for about three months. With the correct selection of components and mixing, the stove will last for many years.