The central heating system of residential premises provides for one common boiler room, from which the heated coolant is distributed through pipes to the houses to consumers. The role of the coolant temperature regulator is performed by the elevator unit of the heating system.

- Device and principle of operation

- Design features

- Possible malfunctions

- Advantages and disadvantages

- Connection diagrams

- Scheme of a heating unit with a water flow regulator

- Diagram of a heating unit with a nozzle regulating the elevator

- Diagram of an elevator unit with a regulating pump

- Safety measures and operation

Device and principle of operation

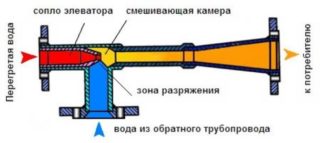

The heating unit elevator is a one-piece cast iron casting, which is a mechanical device that looks like an asymmetrical tee. The only variable part is the nozzle diameter, which affects the degree of vacuum and determines the mode of suction of chilled water from the return. The vacuum value should not exceed 2 bar, for which the nozzle diameter, as the only regulator, is calculated with a high degree of accuracy.

Depending on the tasks to be solved, the elevator of the heating unit is manufactured in several standard sizes, which are assigned numbers from 0 to 7.

- The length of the smallest elevator No. 0 is 256 mm with a weight of 6.43 kg.

- The length of the largest elevator # 7 is 720 mm and weight is 34 kg.

An elevator is selected based on the diameter of the heating pipe so as not to reduce the throughput of the system.

According to technical conditions, main heating systems can operate in three modes:

- 150/70 ° C;

- 130/70 ° C;

- 95/70 ° C.

The first number indicates the temperature of the water in the flow line, and the second indicates the temperature of the chilled liquid in the return line.

The end consumer can be located at a considerable distance from the boiler room - high temperature indicators in a straight pipeline are installed to compensate for heat loss during transmission over a distance and dissipation in cold climatic conditions. At the same time, household heating equipment (batteries, pipes), due to its technical characteristics and sanitary standards, cannot be operated at temperatures above 95 ° C.

There are several reasons for the restrictions:

- at higher temperatures, cast iron batteries become brittle, and aluminum batteries are not able to maintain the pressure of the system and fail;

- modern metal-plastic and polypropylene pipes cannot operate at temperatures above 95 ° C - they begin to deform, cracking is possible;

- overheated heaters can cause burns on contact.

The internal pressure in the heating main does not allow the overheated water to turn into steam. During transmission, due to losses, the temperature of the medium decreases, but insignificantly, the issue of obtaining the coolant of the operating temperature does not solve. To solve the problem, a heating elevator is used, in which the superheated coolant from the boiler room is diluted with a cooled liquid from the return pipeline.

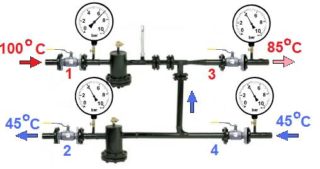

The equipment surrounding the elevator forms the mixing system and is called the "heat elevator unit".

The principle of operation of the device:

- The superheated coolant is supplied to the inlet of the elevator unit, passing through the nozzle, it loses pressure.

- Lowering the pressure causes the chilled water to flow from the return to the vacuum zone.

- In the mixing chamber (long part) the streams are mixed to the specified parameters.

- Through the diffuser (expanding part), the heat carrier of the operating temperature enters the heating system.

In the general scheme, the elevator unit is located on the incoming pipe of the main. A mud sump is installed in front of it, which acts as a trap for dirt and small debris contained in the coolant flow.

The task of the surrounding equipment - valves, pressure and temperature sensors - is to ensure the safe operation of the device and implement the control principles.

Design features

In addition to the one-piece cast iron version, there are other designs that allow mobile change of the nozzle diameter. Such models solve the problems of quick adjustment of the temperature of the coolant, but they are structurally complex and have a high price.

For example:

- Elevator assembly with a tapered movable needle. When moving it, the size of the nozzle clearance and the degree of dilution of the heat flow with the cooled return water are regulated. The needle position can be adjusted manually or automatically.

- A device with a servo drive, which mobilely changes the nozzle lumen according to a signal from temperature sensors.

Devices operating in automatic mode increase the mobility of the system and its capabilities in terms of fine tuning. But due to their structural complexity and high cost, they have not yet found widespread use.

Possible malfunctions

The elevator itself is a reliable device operating in a stable mode. Its only malfunction may be damage to the nozzle, since overheated water is a rather aggressive agent.

Malfunctions can be in the surrounding equipment:

- clogging of the sump;

- valve breakage;

- incorrect operation of the sensors.

Violations in the operation of the elevator and the equipment of the unit appear as fluctuations in the temperature of the coolant and are solved by revising the device, replacing the nozzle, cleaning the sump or repairing the valves.

To prevent malfunctions, regular (once a year) maintenance of the elevator unit is carried out - they clean and remove dirt formed due to the poor quality of the coolant, check the diameter of the nozzle, and monitor the tightness of all connections.

Advantages and disadvantages

The elevator unit as a heat flow regulator in the heating system has been used for a long time, during which the strengths of the system and its shortcomings have been identified.

The advantages of such temperature control include:

- simplicity of design and reliability;

- operates silently;

- does not require power supply to operate;

- poor response to the aggressive environment of overheated water;

- the ability to maintain constant characteristics of the coolant at the outlet;

- combines the functions of a pump and a mixer.

Weaknesses are expressed in several points:

- a differential pressure of 2 bar between the direct and return lines is required;

- works only in one mode;

- in case of violations on the heat pipeline, the system does not work, which can lead to freezing;

- a separate node is required for each building.

The disadvantages of the elevator heating unit are insignificant and are completely covered by the advantages, which explains its widespread use.

Connection diagrams

The heating unit is used in systems with different parameters, where special schemes for connecting the elevator unit are used for stable operation, which require the use of additional equipment.

Scheme of a heating unit with a water flow regulator

The main factor that allows the regulation of the temperature of the heat flow of the heating system is the water consumption. Measurement of this indicator causes fluctuations in the coolant in the devices and makes the operation of the heating system unstable.

To eliminate such phenomena in the system, a regulator is mounted in front of the elevator unit, which ensures a constant flow rate of the coolant.

Such a scheme is extremely important in houses with hot water supply, where there are periods of active water intake from the system (morning, evening, weekend, etc.).

The disadvantage is that when the temperature of the driving heat flow decreases, the circuit is not effective.

Diagram of a heating unit with a nozzle regulating the elevator

The ability to mobilely adjust the nozzle throughput allows maintaining constant indicators of the coolant at the outlet with changes in temperature in the main pipeline.

Nozzle adjustment is effective only if the process is fully automated with the involvement of additional equipment:

- thermal sensor;

- pressure gauge;

- servo, etc.

Such schemes are not widely used due to the requirements for high pressure in the system, the significantly increasing load on the nozzle and high cost.

Diagram of an elevator unit with a regulating pump

This connection scheme is used in autonomous heating systems for private houses. It allows the unit mechanism to function normally with insufficient pressure in the heating network (less than 2 bar between the inlet and return).

A jumper is mounted between the direct heat pipe and the return pipe on which the pump is installed; it is imperative to use a thermostat.

The use of connection schemes with additional capabilities is not always justified - they complicate the system, require electricity supply. The reliability of the system and its complexity are inversely related to each other. Consideration should also be given to the significant increase in the cost of the heating unit and the cost of electricity.

Safety measures and operation

Several general rules to ensure the safe operation of substation equipment:

- personnel must have the appropriate qualifications;

- workers must be familiar with the rules for the operation of the equipment.

The elevator assembly of the heating system does not require special attention - routine inspections are enough. After a scheduled check, it is advisable to seal the system in order to fix the settings and avoid unauthorized interference.