The main element of the heating system of a private house is a boiler. The unit is necessary to heat the coolant, which moves through the pipes to the batteries. The popularity of the devices is associated with the cheapness of the energy carrier, high efficiency and ease of use. The user needs to know the structure of the gas boiler in order to select the correct model and identify possible problems.

Gas boiler design

Before considering the principle of operation and types of heating units, you need to understand their structure. The gas boiler consists of several units.

Primary heat exchanger

It is made in the form of a metal box with a built-in radiator. Pipes are located inside this element. The heat exchanger is heated by gas and supplies heat to the water. Elements differ in the type of material:

- Steel. Inexpensive and simple products that are heavy. The disadvantages of heat exchangers are susceptibility to oxidation and significant fuel consumption.

- Cast iron. Models with a long service life, but only in conditions without temperature extremes.

- Copper. It does not corrode and has a high efficiency. The disadvantage of the unit is the risks of fractures under mechanical stress.

The strength of the copper heat exchanger is increased with a modulating burner.

Secondary heat exchanger

It is included in the boiler device with two circuits, made of copper or structural steel. Secondary heat exchangers differ in the type of circuits:

- Lamellar. Metal products with extruded channels are one-way (the direction of the water does not change) and multi-way (you can change the direction of the water). They are connected by assembly or soldering method.

- Shell and tube. They are manufactured as a pipe with small nozzles. The coolant moves along them, entering the heater or hot water supply.

- Bithermal. They look like two tubes inserted one into one. On the inside, water is supplied to the hot water supply, on the outside - for heating.

Shell and tube models are used for industrial boilers.

Gas-burner

It heats the coolant, it can be supercharged and atmospheric. The supercharged modifications are distinguished by high performance, atmospheric ones - by the minimum noise level.

Pump

The circulation pump ensures the pumping of water along the heating main, its slow cooling. Fuel costs are reduced by means of a pump. Before starting the heating unit into operation, an air lock is evacuated from the pump.

Gas fittings

Reinforcement elements include several devices:

- Fuses - automatically remove water or steam from the system when the pressure is exceeded. For models with a pressure limit of up to 0.07 Pa, blow-out fuses are used, more than 0.07 Pa - lever-weight and spring valves.

- Water indicators - devices in the form of a glass body, pipes and taps control the water level.

- Shut-off and control valves - represented by valves (boilers with a passage diameter of 100-150 mm) and valves. Single-circuit heaters are equipped with non-return valves.

One boiler is equipped with 2 water indicators.

Three-way valve

Adjusts the direction of the heating medium in the presence of a DHW system. The T-piece with one outlet and two inlets is made of bronze. Inside the valve there is a membrane for regulating the incoming heat carrier flows. Automatic three-way valves are activated by the water temperature, mechanical ones are set manually according to the thermometer readings.

Turbine

Installed on models where there is a closed type of combustion chamber and a rotary chimney. The unit is made in the form of a fan supplying air. The streams support the combustion process and remove the combustion products.

Varieties of gas boilers

The classification of a gas boiler is carried out according to several criteria.

Number of contours

A single-circuit device provides only room heating, without hot water supply. The double-circuit unit is connected to the DHW communications and heats the house.

Method of creating thrust

The draft of gas-type boilers is:

- natural - it is realized with a difference in the specific mass of air in the room and outside;

- forced - the fan blows the draft.

For models with natural draft, a high-quality chimney is required.

Ignition method

The operation of the heating boiler starts after activation:

- electronic ignition system - automatically, without user intervention;

- piezoelectric element - the device is ignited after a person presses a special button.

Electricity is required for electronic ignition.

Mounting method

Depending on the installation method, you can select the unit:

- Wall-mounted - fixed on the wall surface with anchor bolts, it is compact. The model is suitable for small spaces. The downside is the sensitivity of heat exchangers to the chemical composition of water.

- Floor standing - installed in a separate room. The boiler room is equipped in accordance with state regulations. A high efficiency version capable of heating a large area.

Floor-standing boilers always have two circuits, wall-mounted boilers may have one.

Heat storage principle

- The convection appliance burns gas by heating the water using a single heat exchanger. During the circulation of the coolant, condensate settles in the chimney and gets into the heat exchanger. The acidic composition of the liquid leads to breakage of the element.

- The condensing unit is equipped with a secondary heat exchanger on which the condensate settles. The residual heat of the sludge is accumulated by the heating element.

The efficiency of convection models is 88-92%, condensation - 103-115%.

Power type

There are several modifications of boilers:

- Single stage. Adjustment of temperature parameters is carried out through switching on and off.

- Two-stage. Combustion can be set to two modes - 40% or 100%.

- Modulated. The power range of the elements varies from 10 to 100%.

Modulating devices provide smooth adjustment of flame height and water temperature, but are expensive.

Operating principle

For central and autonomous heating mains, natural gas is used with methane and propane-butane combustion. Regardless of the burning mixture, the principle of operation of the boiler is presented:

- Connection. If gas is present, manually or automatically, the device ignites.

- Sparking. The burner ignites when a spark is generated from electricity.

- By activating the main burner. The process is carried out using an igniter.

- Heating the coolant and water jacket. A heat exchanger is used to carry out this operation. The element heats up the water to the set temperature parameters, then the burner turns off.

When the temperature drops, when the boiler is running, the sensor transmits signals to the automation. The system begins to function until the coolant is heated up again.

Pros and cons

The positive aspects of operating the equipment include:

- inexpensive cost of gas fuel in comparison with electricity, wood, fuel oil or coal;

- high efficiency;

- connection to DHW and heating models with two circuits;

- selection of installation for large and small houses;

- ease of independent operation;

- compatibility with other devices - a boiler or communications for hot water is connected to the unit;

- the possibility of installing wall modifications in an apartment, floor modifications in a private house.

The disadvantages of gas boiler equipment are the costs of installation work - the connection is made with the permission of Gaztekhnadzor. The efficiency of operating the device is achieved only if there is a gas main.

Selection rules

When choosing a gas-type boiler, consider several criteria:

- Convection models are cheaper than condensing ones, but they have lower efficiency and heat exchangers break down more often.

- Boilers with an open combustion chamber are not suitable for apartments. They are installed in a separate room with a high-quality ventilation system. Better to stay on equipment with a closed camera.

- Power of wall-mounted units - up to 32 kW, floor-standing units - from 100 kW.

- The wall-mounted boiler provides high-quality heating of buildings up to 300 m2. If the house is more than 300 m2, the floor version will do.

- To reduce heat costs, it is better to choose two-stage or modulating devices.

- Appliances with natural circulation are not suitable for rooms larger than 100 m2.

- Floor-standing modifications with a power of up to 60 kW are allowed to be connected in the kitchen.

- Wall-mounted units are low-noise - they can be placed in the kitchen or in the hall.

- A sample with an atmospheric burner requires a separate chimney from 4 m high.

- The forced draft burner (power from 100 kW) must be connected and installed separately.

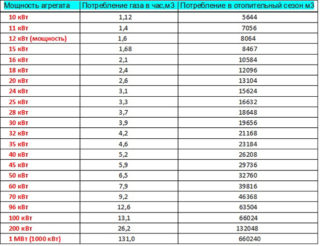

When choosing power parameters, keep in mind that 1 kW of heat heats 10 m2 of the dwelling.

Running gas boilers is an economical way to heat your home. Owners do not need to solve the issue of transportation and storage of solid fuels, overpay for electricity. With knowledge of the varieties and the principle of operation of the units, it is easy to choose an option for a specific room.