The convenient stove stove has been known since the 18th century and still continues to be a more profitable alternative to expensive fireplaces and large stoves. The device gained wide popularity due to its trouble-free operation and simple design, it could be easily made independently, but the main disadvantage of such furnaces was the high fuel consumption. Modern potbelly stoves are most often installed in baths, in summer cottages or in apartments as an element of decor, while their use for their intended purpose is quite economical and does not cause problems.

Principle of operation

The stove stove is a compact device suitable for heating small rooms. With its help, you can quickly heat up a room and maintain an optimal temperature in it for a long period. Such a stove does not require additional equipment, it is easily transferred from one place to another, if we are not talking about a brick stove stove for a summer residence, and is installed without much effort.

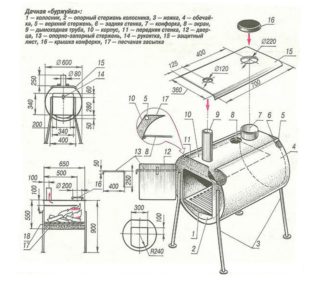

A potbelly stove is not so difficult to assemble on your own, for example, from bricks, barrels or old cylinders. In addition to the main structural elements, it can be supplemented with a heat exchanger, with which it will work much more efficiently. This part provides long burning and the necessary heat transfer when using any fuel. In order for the device to function correctly, it is worth preparing its drawing in advance, where all the details will be taken into account. A standard potbelly stove consists of the following elements:

- long burning chamber;

- ash pan;

- pipe outlet for a standard chimney;

- legs and frame;

- door with a latch.

In equipment of this type, as in other furnaces, a chimney with a door must be present to maintain combustion at the desired level and comply with safety standards.

Varieties of bourgeois

The army stove is presented in several versions and is divided into categories depending on the purpose, materials and type. According to their purpose, such devices are divided into heating options designed for heating rooms, and stoves with cooking surfaces. Cast iron or metal is used as a material for their manufacture. Cast iron devices have a low level of thermal conductivity, but at the same time they are able to retain heat inside the room for as long as possible.

Due to the large weight of cast iron, it is problematic to transport such furnaces, therefore they are installed in one place for a long time. Metal options with special screens quickly heat up rooms, but give off heat faster due to its accelerated release. It is best to purchase metal stove stoves, supplemented with outer metal sheets, which will allow the device to remain hot for a long time even after turning it off. If desired, the stove can be additionally finished with bricks, tiles and other materials.

Classic

Depending on the duration of burning, the furnaces are also divided into two types. The classic version is characterized by low efficiency, fast fuel combustion combined with long heat retention. The special design of the device is made so that the intensity of heat depends on the flow of incoming air.You can install a stove of such a plan in the house or in the country, taking into account the requirements for its installation.

Long burning

Iron wood-burning stoves of this type are more expensive. They have a single-chamber design and require a rare supply of fuel, since in long-term combustion devices it is consumed more slowly. Such stoves are more difficult to ignite, the air is metered inside, the fuel is not added until the previous portion has burned out. They also have their own advantages, including good efficiency, high level of economy and low fuel consumption.

What are stoves suitable for?

Thanks to the primitive and simple design, a stove-fireplace or a stove of a standard plan is suitable for any room that needs full heating. It can be installed in the country, in the bathhouse, in a private or country house. Manufacturers offer a fairly extensive range of such stoves, among which you can find stylish options that can fit favorably into the interior. A stove-stove fireplace, intended for a country house, will be very useful in the cold season.

Inexpensive options with a chimney or a hand will be a real boon for owners of summer cottages and private buildings where gas cannot be supplied. Modern stoves are much better than the Soviet ones in the Russian Federation in terms of heat retention; large devices can also be used to heat rooms with an impressive area. There are also quite expensive options on the market of various sizes with an excellent design and an increased level of fire safety, including bath or wood-burning stoves.

When choosing a device, it is important to determine in advance for what purposes it will be used, since modern stoves are suitable not only for heating. They can be used for cooking or as a decorative item.

Pros and cons of bourgeois

Modern bourgeoisie have much more advantages compared to devices that were popular during the Soviet era. They are compact in size, do not cause difficulties during operation, are combined with various types of fuel and, at the same time, are quite economical in comparison with gas heating devices. Most structures do not weigh that much, so they are easy to transport when needed. They are also easy to mount, this process will be accessible even to a beginner familiar with safety rules.

A practical Armavir or water stove of such a plan heats up quickly and at the same time uses fuel as economically and efficiently as possible, continuously heating the room for 6-10 hours. Cast iron and metal models for a house or garage are durable and do not require special maintenance, and most stoves do not require the installation of a capital type chimney or a special pipe.

Furnaces of this type also have their drawbacks, for example, lack of autonomy and the presence of a risk of fire, which can be minimized if you monitor the device. During operation, it is better not to touch the furnace body to avoid burns, since it always gets very hot.

How to make it yourself

It is easiest to make a potbelly stove yourself from two metal barrels according to the standard scheme. For this purpose, you will need two barrels, one of which should be smaller. The upper part is cut off from each, metal handles and locking-type parts are attached to the remaining part. Before starting work, it is better to rinse the barrels thoroughly to get rid of the unpleasant odor that could remain there. Assembling such a furnace according to the rules consists of several stages, performed step by step:

- A rectangle with an area of 25x10 cm is cut out at the bottom of a large barrel, this compartment will become a compartment for a drawer.

- You need to attach two guides measuring 2.5x2.5 cm to the bottom.

- A pallet is cut out of a metal sheet along a contour with a thickness of no more than 1-2 cm, which will become the basis for the camera and will be able to isolate it from the ash pan.

- In the central part of the pallet and the bottom of a small barrel, cut out a hole with a diameter of 6 cm, after which the pallet is welded at a distance of at least 15 cm from the bottom of the container.

- At the final stage, a hole is made in the body of the large barrel, which is necessary for the gas flue pipe and a convenient flap with a small handle is built into the pipe.

- A small barrel is placed inside a large one so that each hole in them coincides.

To add fuel, a cone with a length of at least 1.5 meters is made, which is made of metal or wood. The bottom of such a cone should pass freely through the hole in the pallet.

Material options

Basically, potbelly stoves are made from metal barrels or gas cylinders, using additional materials and equipment for this purpose. To make a full-fledged device, it is advisable to first prepare a drawing of a future brick or cast iron stove stove and stock up on all the necessary materials. In the drawing, the main and auxiliary parts, for example, a heat exchanger, are indicated in advance. Ovens from a barrel and a cylinder are assembled according to a similar scheme, observing all stages.

A more acceptable option is to build a brick oven, a device of this type has more advantages, it cools slowly and retains heat longer. Also, brick stoves look neat enough in any room. For a collapsible or ordinary stove of this type, there are two construction options; it can be erected using bricks independently according to the standard scheme, or a finished metal stove-stove can be faced with bricks. The choice of option depends on the situation and the amount of free time.

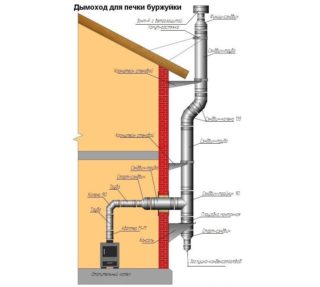

What kind of chimney is needed

It will be impossible to use a stove without a chimney, so you should take care of the manufacture of this part in advance. To make a pipeline, you can purchase ready-made pipes or make them yourself from sheet metal. The second option is cheaper. During the assembly process, a smoke channel is assembled from pipes and a corner element, which is then welded to the finished stove.

Brick, steel or other metal pipes, ceramics, vermiculite or asbestos cement are used as the material for the chimney. The choice of the appropriate option should be based on the budget and the complexity of the installation.

Sometimes chimney pipes are made of special heat-resistant glass, but special skill is required to work with this material. Glass chimneys are also not practical.

The optimal choice for beginners will be ready-made stainless steel pipes, their main advantages: low weight, reasonable price and no difficulties at all stages of assembly.