Underfloor heating is an additional or main heating device. To ensure a comfortable room temperature, the system must be correctly installed. When creating a heating plan that includes underfloor heating, you need to take into account various indicators, which include the annular distance. Its calculation depends on many individual parameters of the room.

System advantages

When arranging a residential building, it is important to pay attention to heating. A comfortable and economical way is to create a warm floor. It allows you to save up to 30% of heat at a ceiling height of 2.5 m and about 50% at a height of more than 3.5 meters. A water heat-insulated floor is a complex design, when creating it you need to take into account many factors.

The advantages include:

- Heating of the entire area of the room. For this, the most comfortable method is used - the greatest warmth at the bottom and lower temperatures at the head level.

- No strong convection. The heat does not rise to the ceiling level, so there are no unnecessary costs and losses. This also translates into savings.

- No contamination of the system and its hygiene. Dust builds up quickly on radiators and can interfere with equipment operation. The water floor accumulates less dirt, it is easier to remove it.

- Underfloor heating takes up minimal space. Providing maximum warmth will not be hindered by furniture and partitions.

- Safety. The design does not harm the environment and human health.

- System availability. All the materials you need can be found at any hardware store for a variety of budgets.

- Strength. Subject to the installation conditions and proper operation, the floor will serve for decades.

- Self-regulation of the system. It turns on and off when the preset temperatures are reached. This also leads to significant savings and the absence of waste of thermal energy.

It is possible to create comfortable heating only after careful calculations of the warm floor and communications that ensure the movement of the coolant.

Factors taken into account in the calculation

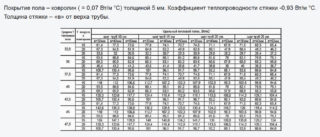

Influence of the thermal conductivity coefficient

It is necessary to familiarize yourself in advance with all types of pipes that are traditionally used to heat a house with a warm floor. The following materials conduct heat best in descending order:

- copper;

- steel;

- metal plastic;

- cross-linked polyethylene;

- polypropylene.

The higher the thermal conductivity, the larger the pitch between the pipes. The best option is corrugated pipes made of copper and steel, but they are rarely used for a water-heated floor due to their high cost. Polypropylene pipes conduct heat worst of all. They are also rarely used due to their poor elasticity.

Effect of pipe diameter

The section of the pipeline also affects the distance.The smaller the diameter of the main element of the system, the smaller the distance should be between the loops in the underfloor heating circuit. The pipe pitch of 16 mm will be 10-15 cm. If the diameter is 20 mm, the pitch is 15-20 cm.

It is recommended to use elements with a diameter of 16-25 mm, so as not to impair the efficiency of the heating system.

Heat loss and location

The heating circuit is a complex system, therefore the spacing between the loops may not be constant. If underfloor heating is used in rooms with strict air temperature requirements (bathroom, industrial facilities), the step can be constant. The following values are respected:

- Large industrial premises, swimming pools, water parks - 20 cm between loops with a pipe diameter of 20 mm.

- Bathroom - laying step 15 cm.

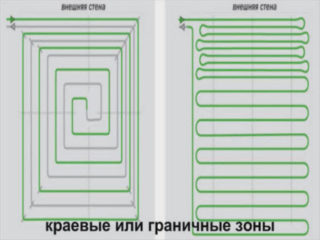

In other cases, the values are approximate and unequal along the length of the entire pipeline. It is necessary to observe the minimum distance between the turns along the walls, since the greatest heat losses are observed here. With distance from the walls, the step increases. If the heat losses of the hot pipes are less than 50 W / m2, the step will be 30 cm. If the heat loss is exceeded 80 W / m2. the minimum step must be observed.

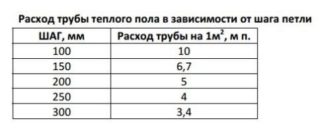

Traditionally, pipes are laid in such a way that there is a distance of 100-300 mm between them. More accurate values are obtained after a general calculation.

The approximate distance in the bathroom is 10-15 cm. In the living room, the interval increases to 25 cm. For corridors, kitchens, storage rooms, the optimal value is 40-35 cm. The values may vary in different parts of the room.

Styling forms

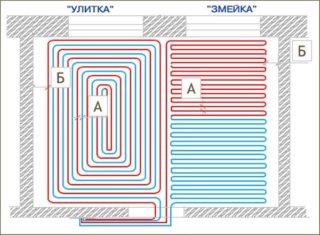

The way the pipeline is laid also affects the efficiency of underfloor heating and the distance between pipes. The most popular are snake and snail. How to roll out a warm water floor depends on the individual characteristics and purpose of the room.

Snake

With this method of placement, pipelines are laid parallel to each other. The room is heated unevenly, so the method is used in small rooms. It also requires additional heating from radiators and a small distance between the pipes.

In the case of using a corner snake, the pipe is laid along the outer corner, and the next turns are laid in parallel.

With a double snake, the beginning and end of one contour are laid in parallel. This method provides the most even heating of the room.

Snail

This method is also called a shell or a spiral. The pipes are laid in a spiral, which ensures uniform heating of the entire room. Suitable for use in large rooms.

Which method is better

The best effect can be achieved by combining two communication methods under the floor covering. In large rooms (living rooms, halls), a snail is used, and in small rooms, a combination of different types of snake. An ordinary snake fits in the bathroom, corridor. The rooms are medium in size - double. The corner method is used only for combined installation.

If a combined option is used, it is better to additionally heat the following zones and lay them with a snail:

- an area near a work table, piano or other object where a person sits motionless for a long time;

- play part of the children's room;

- places next to the bed, sitting area with upholstered furniture.

The layout of pipelines with all distances is pre-drawn and sections are separately allocated where more / less intensive heating is needed. Only then can the pipes be laid under the warm floor.

Installation recommendations

You can do a high-quality installation with your own hands. To do this, you need to adhere to the basic rules:

- Do not change the approved pipeline layout during installation. The developed plan has been calculated, therefore, the slightest changes will lead to a malfunction of the system.

- The coolant should not be subjected to mechanical stretching, heating, deformation.

- The pipes must be cut off before connecting them to the pump.

- Do not step on the thermal fluid during installation work.

- To make the pipes easier to lay, you can use a lined foil backing.

Observing the listed recommendations, you can make high-quality pipe laying for a warm floor.

Features of pipe fixation

You can fix pipes under a warm floor in one of the following ways:

- plastic strips;

- rugs that have laying grooves;

- metal tapes;

- separate brackets.

The most convenient installation method is to fasten the circuit to the clamps. When using point brackets, a distance of 20-25 cm is observed. They are used for uniform heating of the screed, regardless of the chosen laying method.