Independent design, selection of components and installation of a heating system is one of the most difficult activities. Most often, they try to initially reduce the complexity of performing these stages. For this, preference is given to an open heating system. Expansion tanks, circuits, pumps - how to correctly determine the optimal parameters for these heat supply components?

Features of the arrangement of open heating

The classic open-type heating system for a private house differs from a closed one in terms of pressure. It is equal to atmospheric. Therefore, for the arrangement of this type of heat supply, much less components and accurate calculations are required. But this does not mean that an open heating scheme can be drawn up unprofessionally.

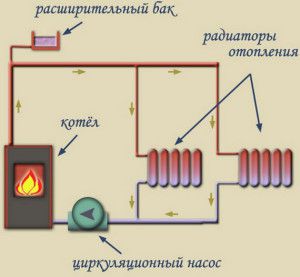

For automatic stabilization of the coolant pressure in the pipes, an open expansion tank for open heating is provided in the system. It is the design of this component that distinguishes the open heat supply scheme from the closed one. The movement of the coolant can be carried out in two ways:

- Thermal expansion of hot water... This requires an accelerating riser. According to this scheme, an open heating system with natural circulation is designed;

- Installation of pumping equipment... It allows you to increase the speed of movement of the coolant. A pump in an open heating system is required if the total length of the lines exceeds 25 m.

In addition, it is necessary to reduce the friction index of the water as it passes through the pipes. For this, the diameter of the latter must be at least 30 mm. Otherwise, the hydraulic resistance will increase, which will reduce the natural circulation.

The defining component in the scheme is the boiler for an open heating system. It is important not only to choose the right design and principle of operation of the device, but also to comply with all installation rules.

Despite the fact that the cost of an open heating system with a pump will be significantly lower than that of a similar closed system, the installation of the first is difficult. This must be taken into account when designing heat supply.

Choosing an open heat supply scheme

At the first design stage, it is important to choose the right scheme for an open heating system with a pump. It depends on the parameters of the house, the required thermal mode of operation of the heat supply and financial capabilities.

Consider the main parameters that will directly affect the choice and further calculation of an open heating system:

- Total area of heated premises... If this characteristic is less than 60 m², a gravitational system can be installed;

- Number of storeys of the house and ceiling heights... For the gravitational system, a prerequisite is the presence of a booster runoff. Without it, air may appear in an open heating system and circulation will deteriorate;

- Estimated thermal mode of operation... For low-temperature, an open heating system with a circulation pump is used.Otherwise, a slight expansion of the water will not create the necessary circulation.

Only after a thorough analysis of these indicators, as well as the calculation of heat losses in the house, can it be decided whether to supply open-type heating with or without a pump.

It is best to calculate the heat loss of a building using specialized programs. Their demo versions are distributed free of charge.

Gravity heating system

The main difference between gravity and the rest is the complete absence of any mechanisms for the forced movement of fluid through pipes. Those. this process is carried out only by the thermal expansion of hot water.

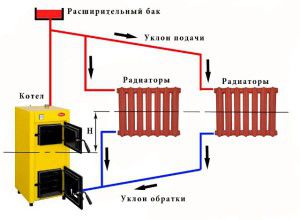

For the correct operation of the heat supply, an accelerating riser must be installed. It is mounted directly after the boiler and is positioned vertically. Its height must be at least 3.5 m. If this condition is not met, then the heated liquid coming from the boiler for an open heating system will not have sufficient speed.

In addition to this factor, it is necessary to take into account the following specifics of the organization of an open heating system with natural circulation:

- Mandatory pipe slope. The supply line from the riser must be inclined towards the heaters. The return is to the boiler. Slope level - 1 cm per meter;

- The boiler is located at the lowest point in the circuit;

- For normal operation, open-type expansion tanks are needed for heating systems. They are also mounted for forced circulation circuits.

It is not recommended to install an electric boiler for an open gravity-type heating system. The same as the gas counterpart. This is due to the high probability of air pockets, which can lead to overheating of the heat exchanger.

To increase the efficiency of work in an open heating circuit with natural circulation, the diameter of the booster pipe should be 1 size smaller than the cross-section of the main line.

Forced circulation in heating

Recently, the owners of private houses and summer cottages have been modernizing the heating system by installing only one component - a pump. It is designed to improve the circulation of the coolant.

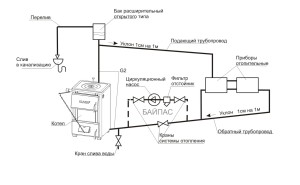

In general, the arrangement of an open heating system with a circulation pump is no different from the above. It is important to choose the right location for the pump. It is mounted on the return pipe in front of its entrance to the heating boiler. The optimum distance should be 1.5 m.

For this open heating circuit, the following points must be considered:

- The pump is installed on the bypass. This is necessary to ensure the circulation of water in the event of a breakdown or a power outage;

- A check valve must be installed. It will prevent the appearance of the reverse circulation effect;

- During installation, the direction of movement of the coolant is taken into account.

The advantage of using an open-type heating circuit with a pump is to reduce the inertia of the system. Due to the increased circulation, the batteries and radiators will heat up faster.

For an open heating circuit with a circulation pump, its parameters should be calculated - pressure and performance.

Complete set of open heating system

In addition to the pump in an open heating system, other components must be selected. The performance and efficiency of the entire heat supply scheme will depend on the correct choice.

For the correct calculation of an open heating system, its rated power is first calculated. If the thermal insulation of the building is good, you can take the ratio that 1 kW of heat energy is required for 10 m² of the area. For a more accurate calculation, it is recommended to use special programs.With their help, you can draw up a correct open heat supply scheme, calculate the optimal characteristics of its components.

For the minimum configuration of the heating system, you will need the following elements:

- Boiler;

- Expansion tank;

- Pipelines;

- Radiators and batteries.

The requirements for the last two are low. Most often, polymer pipes are used for arranging heat supply. But experts recommend using a steel pipe for the booster riser. This is due to the high temperature in this part of the open-type heating system for a private house.

Almost all models of polymer pipes are designed for temperature exposure no higher than + 90 °. This should be taken into account when completing the system.

Choosing a boiler for open heating

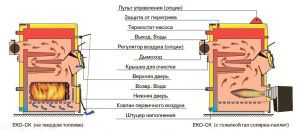

First of all, it is necessary to warn that the installation of gas and electric boilers for an open heating system is prohibited. Often, air locks form in the system, which will negatively affect the operation of the equipment and can lead to emergency situations. Therefore, the only alternative is solid fuel models or diesel boilers.

The boiler must be installed in accordance with all requirements. It is located in a separate room where fuel cannot be stored. The boiler room must have forced air circulation. To optimize the operation of the equipment, it is recommended to install sandwich chimneys.

In addition to these factors, there are specific requirements for the normal adaptation of the boiler of an open heat supply system:

- Long burning boilers must not be installed. They are designed for low temperature system operation. In this case, the expansion of the coolant will not be enough for circulation;

- If a pump group is not installed in the system, a separate installation of a check valve is required;

- A boiler in an open-type heating system for a private house should be located at the lowest point of the circuit.

If the equipment does not include a temperature sensor, it must be installed separately. For accurate measurement, it is mounted on the supply pipe directly after the boiler.

To remove air in an open heating system, installing an air vent will not solve the problem. It only works if the pressure in the system is above atmospheric.

Expansion Tank Models for Open System

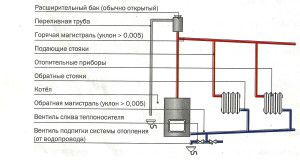

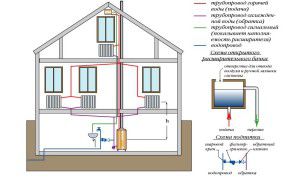

To compensate for the thermal expansion of the coolant and timely control of its level, it is necessary to install an expansion tank for open heating. It is located at the highest point of the system and can perform several functions at once.

First, the optimal volume of an open expansion vessel for heating systems is calculated. It must be at least 5% of the amount of heating medium in the system. In the standard design, there are 3 nozzles, which perform the following functions:

- Inlet pipe... With its help, the expansion tank is connected to an open heating system. Usually, its diameter is 1 size smaller than that of the booster riser to which the installation is performed. Therefore, an adapter is required;

- Circulation pipe... Through it, hot water enters further along the main line;

- Signal connection... It is necessary to notify about a critical decrease in the level of the coolant. When you open the tap, no water comes out of it - the system must be refilled.

Additionally, the expansion vessel for open heating can be retrofitted. In some cases, it can act as a make-up unit. This requires an additional pipe that connects to the water supply. In case of a critical decrease in the volume of hot water, you can quickly add to the system by opening the shut-off valves.

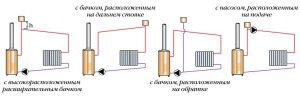

There are several installation schemes for the expansion tank.For open-type heat supply with a pump, it can be mounted on a distant riser. This option is rarely used, since the effectiveness of such a scheme is extremely low. Most often, the expansion tank is installed on the near riser for timely monitoring of the heating condition.

It is forbidden to use polymer materials for the manufacture of the expansion tank. For this, steel is best suited.

DIY open heating installation

After the correct calculation of the open heat supply system and the selection of all components, you can proceed with the installation. It is preliminarily recommended to draw up a layout diagram of all elements with their technical characteristics.

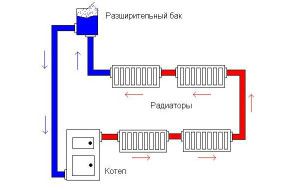

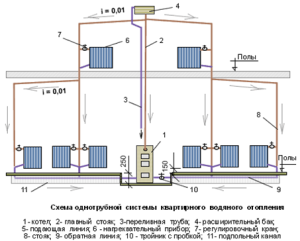

First, we decide on the pipe layout. It can be of the following types:

- Single pipe... In it, devices are connected to the system in series. Advantages - simple installation, a minimum of consumables. Disadvantages - rapid cooling of the coolant;

- Two-pipe... A return line is installed to drain the cooled water. In this way, the heat distribution throughout the entire system can be optimized.

In any case, it is necessary to install an open-type expansion tank for heat supply systems. Tees are installed for branching pipelines. Collector circuits for an open heating system with a pump are not used.

Work is best done in summer. The installation of pipelines requires special attention, since it is imperative to observe the angle of inclination. If the value of this parameter is insufficient, a significant deterioration in the circulation of hot water is possible.

In the video, you can get acquainted with the specifics of heating with natural and forced circulation: