When choosing a specific heating scheme, one should start from the principle of expediency and compliance with the operational characteristics of the house. For premises with a small area, it is important to strike a balance between the total cost of the elements, operational efficiency and planned costs. Therefore, a flow-through heating system is most often installed: boilers, heaters, pumps for which must be selected according to certain requirements.

Features of the flow heating circuit

What is the specifics of arranging the selection of components for this system? A flow-through heating system, first of all, is characterized by the rules for connecting radiators and other heating devices. They are mounted in series, as a result of which the energy from the coolant is distributed in the same order.

Based on this, it can be seen that the degree of heating of the first radiator connected to the flow heating boiler will be significantly higher than that of the latter. In addition, you need to consider the following features:

- The selected instantaneous electric heating boilers must have a relatively high power. In most cases, the ratio of 1 kW of energy per 10 m2 of area will be incorrect. To the resulting figure, it is necessary to add from 15% to 30%, depending on the length of the highway and the degree of thermal insulation of the house;

- The impossibility of regulating the heating level for each radiator. In this case, the volume of the incoming heat carrier into the subsequent batteries will decrease. This may be the reason that a flow heater for heating will not be able to provide heat to all rooms in the house;

- Increased hydrodynamic resistance. Even powerful flow heating pumps will not be able to create the proper fluid circulation rate due to the large number of radiators. Therefore, a one-pipe flow-through heating system needs careful calculation.

However, in addition to these disadvantages, one must also take into account the positive aspects of using such a scheme. The main one is the minimum cost when purchasing components. The serial connection of the system elements does not provide for an additional main circuit as in two-pipe heating.

When calculating a one-pipe flow system, the diameter of the line must be taken into account. The larger it is, the lower the hydrodynamic resistance indicator.

Types of flow heating

One of the most important steps in choosing a heating scheme is its type. The movement of the coolant can be carried out by gravity (gravitational) or using pumping equipment (forced). This affects the operational and quality characteristics of the heating system of a house or apartment. Let's consider the features of each of these schemes.

Gravity heating

The simplest flow-through system is made gravitational. For its organization, flow-through heating boilers, an open-type expansion tank or a membrane one are needed. The transport line for the coolant is a pipeline that delivers water to the radiators and the boiler for reheating.

The main element is a flow-through boiler for heating. It must provide an optimal level of temperature conditions.It is from him that the rate of water circulation in the pipes will depend on it in the future. When the coolant is heated, it expands, as a result of which it begins to move along the highway. As it passes through the radiator pipes, the water temperature begins to drop. The cooled liquid flows through the return to the boiler for reheating.

The features of the gravitational flow-through heating system include the following:

- The short length of the pipeline - up to 30 m. This is due to the low circulating pressure;

- A flow-through electric boiler for heating is rarely used for this scheme. Most often, preference is given to solid fuel models;

- High degree of inertness. The speed of passage of hot water through the pipes directly depends on the parameters of the boiler, the presence of swivel nodes and branches in the circuit. Therefore, the heating of radiators in rooms farther from the boiler will be relatively slow.

Most often, the gravitational flow heating scheme is used for small houses or apartments. The positive qualities include its relatively low cost, as well as the ability to install a small flow heater for heating a house.

To create water circulation after leaving the boiler, a vertical riser is installed, the height of which should not exceed 5 meters. The heated liquid creates the required pressure for the further movement of the coolant.

Heating with forced circulation pumps

To improve performance, a circulation pump is added to the flow-through heating system. This contributes to the fastest speed of water movement, which reduces the inertness indicator. Most often, an increased pressure of up to 3 atm is created in the line. As a result, the boiling point of the water rises and the likelihood of air pockets decreases.

If there is no main gas in the house or apartment, a flow-through electric heating boiler is most often installed. Their advantage lies in the possibility of choosing both single-circuit models (only for heating) and double-circuit (heating and hot water supply).

Since the forced circulation system in most cases is made of a closed type, it is necessary to provide for the installation of additional equipment. The main one is a sealed expansion tank installed on the return pipe in front of the heating boiler. Manometers and thermometers are also mounted. At the same time, the flow-through heating boiler must also have similar devices. The result is an effective system for maintaining a comfortable temperature in the house with the following distinctive characteristics:

- Low degree of inertness;

- Subject to the installation technology and the selection of components, a long, maintenance-free service life is ensured;

- The ability to create a temperature regime at the maximum level - 95/60 degrees;

- There is no need to install a booster riser, which is required for gravitational heating.

The disadvantages of forced circulation heating include increased requirements for pipes and radiators. They must withstand the maximum allowable pressure and the specified operating temperature. This scheme is applicable for houses with a large area of up to three floors.

When creating a scheme with forced circulation, it is recommended to purchase two-circuit electric flow-through heating boilers. Even if the house has a DHW system, you can use an additional one as a spare. The difference in cost between single-circuit and double-circuit models is small - about 10-15%.

Choosing a flow-through heating boiler

Having decided on the type of system, you need to choose the right flow heating boiler. It is on its parameters that the efficiency and efficiency indicator will depend. The main difference for them is the type of fuel used.Manufacturers currently offer solid fuel models that run on gas or liquid fuels. Electric boilers are no less popular.

In addition, there are general recommendations for choosing a flow-through boiler for heating:

- Rated power. This parameter can be calculated in two ways - depending on the quadrature of the room or the total volume of the coolant. In the first case, the power of an instantaneous heater for heating a house must correspond to the ratio per 1 kW of energy - 15 liters of water. With normal thermal insulation of the outer walls of the house, it can also be taken into account that to maintain a comfortable temperature by 10 sq. 1 kW of power is required;

- The presence of a second circuit. It serves for hot water supply and is more than relevant when organizing heating in a private house;

- Dimensions and requirements for the room where flow-through heating boilers will be installed. For solid fuel, it is necessary to make a separate boiler room that meets the standards of DBN V.2.5-20-200. Gas and electric models can be installed in the kitchen, but only if their power does not exceed 200 kW;

- Possibility of connection to external temperature sensors for automatic regulation of the degree of water heating. This is necessary to optimize energy consumption, which directly depends on the temperature in the room and outside;

- The presence of a heating flow pump and an expansion tank in the housing.

These are just general recommendations for choosing a flow-through boiler for heating. Despite the popularity of gas and solid fuel models, attention is paid to electric ones. Although they have a number of unique qualities.

Along with foreign manufacturers, there are currently a number of Russian companies producing reliable boilers for flow-through heating systems: Romstar, Galan and Evan. Their products are significantly lower in price, and their functional qualities and performance are more than acceptable.

Electric boiler for instantaneous heating

First you need to find out the relevance of installing this type of heating equipment. The advantages of flow-through electric boilers for heating are their small size. Unlike solid fuel or gas types, electric ones do not have a combustion chamber as such. This affects their size and weight. The reliability of the equipment should also be noted. Average service life can range from 20 to 40 years. But this is subject to compliance with the rules of operation.

The main disadvantage of an electric flow-through heating boiler is the high cost of the energy carrier. Therefore, it is installed only in the absence of a gas main and as an alternative to solid fuel models. To select electric flow heating boilers, their types should be considered. The design specifics depend on the type of heaters.

Heating element

The heating element is used as the main heating element. Inside the sealed tube is a coiled wire made of high resistance metal. When electrical energy is supplied, heat energy is released, as a result of which the heater for heating of the eastern type begins to increase the temperature of the water.

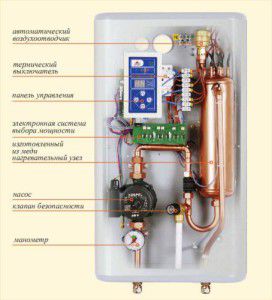

The design consists of the following blocks:

- Heating unit... It houses the heating element, which is washed by the coolant of the heating system;

- Control block... Designed for manual or automatic power adjustment of the heating element;

- Air vent... Not all manufacturers install this security feature. But in case of overheating of the coolant in the flow-through boiler during heating operation, the air vent will promptly remove the airlock;

- Additional accessories - circulation pump, pressure gauge, automatic shutdown system in the absence of water.

Also, when choosing, you need to pay attention to the manufacturers of a flow heater designed for heating a house.The most popular brands are considered to be products from Bosch, Protherm and Dakon.

| Model | power, kWt | Cost, rub. |

| Bosch Tronic 5000 H | 18 | 63800 |

| Bosch Tronic 5000 H | 36 | 90500 |

| DAKON DALINE PTE 10 | 10 | 53560 |

| DAKON DALINE PTE 24 | 24 | 62000 |

| PROTHERM SKAT 12K | 12 | 46410 |

| PROTHERM SKAT 24K | 24 | 57450 |

An important factor is the manufacturer's warranty and the availability of service centers for the prompt repair of a flow heater for heating. It is recommended to find out this information before purchasing.

Induction flow-through heating boiler

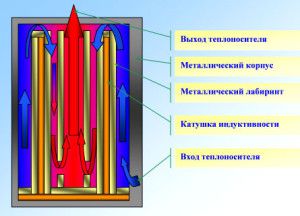

This is a relatively new type of instantaneous electric boiler designed for heating small rooms. Its advantages are small overall dimensions and reliable operation.

To heat water, an electromagnetic coil is provided in the structure. A core is located inside it. When connected to the mains, an electromagnetic field is created, which provokes heating of the core. In turn, it is washed by the coolant flow. Thus, water is heated using an induction flow boiler for heating.

The advantages of installing this equipment are as follows:

- Small size and weight. They are even smaller in comparison with models equipped with heating elements;

- The efficiency of the device can reach 99%;

- Durability and reliability.

However, along with this, their main drawback should be noted - their high cost. It is not always advisable to buy a 10 kW boiler at a price of 45 thousand rubles for a one-pipe flow-through heating system. It should be borne in mind that the package will not include a circulation pump and an expansion tank.

| Model | power, kWt | Cost, rub. |

| VIN-10 | 10 | 45000 |

| VIN-25 | 25 | 60000 |

| Miratron | 12 | 60000 |

| Miratron | 24 | 85000 |

What else is needed to create a flow-through heating system in addition to boilers and heaters. Pumps are also a must for forced water circulation. Their power directly depends on the calculated hydrodynamic resistance. Therefore, before buying a flow pump for heating, you need to calculate the system using a special program. In conjunction with a properly selected boiler and piping, you can get effective and reliable home heating.

For those who want to do this on their own and at a professional level, the video material will help: