Self-construction of a fireplace or stove involves a choice of refractory materials and mixtures. They prevent the fire of the structure, do not let smoke and combustion products pass through. These requirements apply not only to building materials, but also to the solution for the fireplace, which must be durable, ductile and heat-resistant.

Choosing clay for mortar

The cement mixture used for stone structures does not withstand high temperatures. For this reason, clay is used to erect the frame of a fireplace or stove. The material can be purchased in stores or you can dig it yourself on the banks of a river or the slope of a ravine. The burial depth usually does not exceed 0.5 m.

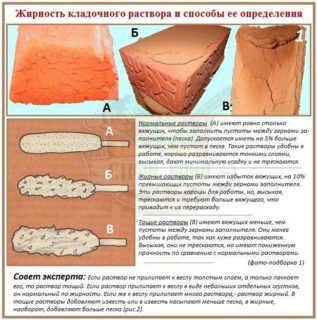

Determination of fat content

Clays are classified as normal, skinny, and oily. Using a mixture based on lean rocks will lead to brittleness and crumbling of the layer. It will not have strength and good adhesion to the surface. You can correct the situation with the help of oily clay.

- Remove coarse fractions from 1 liter of clay and divide it into 5 parts.

- Divide the portions into separate containers.

- Do not add anything to the first part.

- Add sand equal to ¼ portion of clay to the second part.

- To the third part, add sand in ½ portion of clay.

- Mix the same amount of sand with the fourth.

- Mix 1.5 times more sand to the fifth.

Additionally, water is added to each container. The solution is mixed until the "cool" state - homogeneous, plastic, not sticking to hands.

Then a ball is rolled from each portion and placed between the polished bars. One of them is pressed until cracks appear on the ball. Reducing the gap between the two planks by half indicates the fat content of the mortar. If it was a bar with portion No. 5, then the clay is oily or there is an excess of sand in it. A normal mix will crack when the lumber approaches 1/3 of the original distance.

It is impossible to use only greasy clay - the solution can crack, shrink. The material can be normalized with sand.

Clay cleaning

To prepare the clay for work, it is filtered through a sieve with cells of 3 mm - under a masonry seam equal to 3-5 mm. Particles with large fractions will damage the seam.

The second option for cleaning clay is alluvial. Cleaning is carried out in a long trough set at a 7 degree slope. Water is poured into the lower part of the container, and clay rock is poured into the upper part in portions. With a spatula or trowel, a liquid is pumped in, which will wash the clay down. At the last stage of preparation, the material is filtered.

The amount of clay and water is chosen so that they do not interact with each other.

Before preparing the solution, clean clay is soaked in a container. Fill in a layer 10-20 cm thick and moisten it with water. The material reaches full impregnation and softness in 24 hours. It will need to be mixed with a bayonet shovel, spilled and left for another 24 hours.

Solution composition

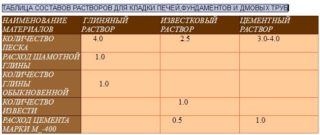

It is allowed to use a mortar with a volume of 8 times less than the volume of bricks or 10-13 times less than the volume of the entire structure for laying a fireplace or stove. The indicator is calculated according to the external dimensions.

To exclude mathematical calculations, the standard ratio of the components is taken: for 100 bricks, approximately 25 liters of the mixture are needed. Additional strength is achieved by adding 100-150 g of salt per 10 liters of solution. For a similar purpose, Portland cements are added in portions - 0.5-1 kg per 10 liters of solution.

The mixture with Portland cement quickly hardens, so you need to prepare it for a one-time installation.

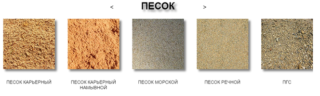

The nuances of choosing and processing sand

Sand is processed by flushing:

- Make a homemade sieve. 4 boards 5-10 cm wide are knocked down into a square box. Burlap is pulled to the bottom, nailing it with small nails.

- The product is installed at an angle on a support.

- The sand is poured into the container in portions and poured with water from a hose.

- Dirt and dust, along with liquid, seeps through the burlap.

You can control the quality of the flushing by the purity of the water.

Varieties and properties of fireplace solutions

The mortar for laying the fireplace stove must ensure the strength of the fastening of all structural elements. Its preparation should begin with the selection of ingredients and determination of their properties.

Main masonry

The proportion of clay and sand is 1: 1, but with oily clay, 2 parts of sand are taken. When finished, you should get a creamy "dough". When making a solution for the main masonry, several nuances must be taken into account:

- Introduce clean and fine sand without additional fractions into the composition - the mixture will be homogeneous, and the fireplace seam will acquire evenness and subtlety.

- Clay has a different ratio of clay, sand and dust particles. It is possible to visually identify the lean, with minimal stickiness, by the presence of sandy elements. Normal material has a homogeneous structure, oily material is sticky and viscous.

- The brick is laid on a plastic, non-aqueous solution. The mixture is checked by moving the trowel. Dry will tear, wet will swell, normal will move evenly.

- Drinking water is allowed to stand for 24 hours before preparation.

Knead the clay dough with a drill and mixer attachment.

Foundation and outer part of the chimney

- Prepare a dough of lime with 3 parts water and 1 part quicklime. The ingredients are mixed until softened clay.

- Prepare a working solution of 3 parts sand and 1 part dough. To increase the strength, cement is added, but the proportions are changed. You will need 1 part cement, 8-10 parts sand and 2 parts lime paste.

- Strain the material through a 3x3 mm sieve.

- Check the quality of the solution by stirring it with a wooden spatula for 3 minutes. The skinny composition will not stick, the oily composition will stick in a thick layer and will be difficult to remove. Normal dough will cover the shoulder blade with clots or stick to it in a layer of 2-3 mm.

- Adjust the ductility. Lime dough is added to the skinny material, and sand to the oily material.

Lime building material can be stored for up to 7 days.

Plastering works

Before decorative finishing, the fireplace is lined by applying plaster. Clay dough should be hardened by adding various ingredients. There are several recipes.

- With lime. The proportion of the components is selected on the basis of 1 part of clay, 2 parts of sand, 0.1 part of asbestos and 1 part of lime.

- Lime-free.You will need to mix 1 part clay with 1 part cement, and then add 2 parts sand and 0.1 part asbestos.

- With plaster. The preparation of the solution is carried out in small quantities due to the rapid adhesion of the gypsum. One portion needs 1 part sand, 1 part gypsum, 0.2 parts asbestos and 2 parts quicklime.

Regardless of the type of building material, each component is carefully measured and sieved. The components are combined dry. Water is mixed with clay to a creamy state and poured into a dry mass.

For tiles

Ceramic tiles are a popular decoration material for fireplaces or stoves. The use of pure clay mortar is unacceptable due to low adhesion. Cement dough is also not suitable because it cracks when exposed to heat. For high-quality fixing of ceramic tiles, you can use the following recipe:

- 1 part cement;

- 1 part clay;

- 2 pieces of sand;

- water in the right amount.

Reliable fastening of the cladding is achieved by filling the joints so that there is a 5 mm void outside. This thickness facilitates the penetration of the solution into the space and the strength of the adhesion of the masonry to the finish.

Stages of self-preparation of the solution

You can make a solution for a fireplace masonry with your own hands after preliminary selection of clay and sand. When performing work, the following technology is observed:

- Preparation of materials. The clay is soaked with water and sieved through a fine mesh sieve. The sand is cleaned to dry.

- The sand is mixed with clay and once again passed through a sieve to obtain homogeneity and crush possible lumps.

- The mixture is tested for plasticity - it should slide smoothly off the trowel or shovel. With this condition, a reference seam thickness of 3 to 5 mm is achieved.

- Increasing the strength of the solution. You will need to add ¾ l of Portland cement to 1 bucket of the composition or table salt in the amount of 150-250 g. The cement is diluted with a liquid until a creamy state, the salt dissolves in water.

For laying flat bricks for a fireplace in the amount of 100 pieces with a seam of 5 mm, 2 buckets of mixture are required. When building a Russian stove, material consumption increases by 20%.

When self-laying a fireplace structure or stove, it is necessary to check the quality of the mortar. The operating time of the structure, protection against carbon monoxide and fire situations will depend on the ratio of the components.