The reliability and performance of heating will increase the collector group for a warm floor. This unit will simplify operation and installation. It can be repaired at any time without reducing its functionality. The device is a mechanism distributing the flow of the coolant between the boiler or the supporting line and the warm floor.

The main types of collectors

The scheme of operation of the device is as follows - water from the boiler enters the storage tank. Such a tank is located at a height above the "comb". The coolant enters the distributor with shut-off and control valves. From the distributor, the streams diverge in separate branches. The outlet pipes are assembled at the bottom of the "comb" to be sent to the boiler for heating.

Usually, the unit is a piece of pipe with a certain number of bends. As the technical task becomes more complex, the complexity increases tenfold, the complexity of setting up the automation, installation becomes much more complicated.

Stainless steel

Collectors made of stainless steel are stronger than brass ones. They have a large flow area that equalizes the pressure of the flows of different heat carrier consumers. The Valtek manifold for heating is designed for an average of 50 years of operation at a pressure of 10 atm. and temperatures up to 130 degrees.

Branded models are reliable - even the appearance of a welded seam does not lead to corrosion. Buying models from cheap manufacturers, you can run into low-quality metal and surface corrosion.

Made of polypropylene

Polymer comb is made of polypropylene pipes. This lightweight material is not as durable as steel, but it will successfully serve for more than one year. Plastic manifolds are extremely cheap. The use is justified when the coolant is circulated in several heating devices. If the main task is to save money, this option is suitable.

The stores offer models with fittings and manifolds with slam-shut valves.

To switch to a metal product with a thread, combined fittings are used.

Plastic combs are common in Ukraine. To strengthen the structure, up to 30% fiberglass is added to PA66 polyamide in factory-made technopolymers to increase strength.

The disadvantage of polymer products is thick walls. They reduce the cross-section of the passage with the same size of the part. Steel assemblies are stronger, the walls can be made thinner - the internal section increases and passes several percent more liquid per unit of time under the same conditions.

Another disadvantage of polymers is oxygen permeability. Fiberglass reinforcement keeps it to a minimum. But oxygen diffusion is present.

The advantages of polymer products are resistance to aggressive environments, electrochemical corrosion, low thermal conductivity. For the same tube length, the polymer loses less heat than steel or brass.

Brass

This material is the leader in the manufacture of combs. For production in Europe, a hollow brass rod is made. For decades, products have been made from it - cut to the required length, drilled holes for flow meters, valves, and cut threads.Stamped models are also present on the market.

Due to rising prices for brass, manufacturers switched to cheaper materials - steel and plastic. However, brass models are still preferred. They have one drawback - zinc leaching. But it is leveled by chrome plating or nickel plating of the surface.

In low-temperature conditions, the advantages of small expansion of brass are leveled and are relative.

Design features

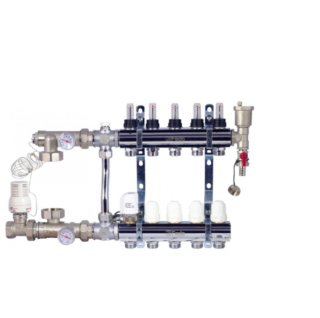

Because of its characteristic appearance, heating system installers call the collector a "comb". This is a tricky knot. He knows how to redirect the incoming heat carrier flows to different heating circuits of the floors. Advanced devices de-air the coolant, regulate its temperature and supply volume.

The collector acts as an intermediary between the boiler and the consumer. Consists of 2 nodes:

- feed comb for coolant delivery;

- return comb for returning the cooled heat carrier to the boiler or main pipe.

A pair of combs makes up a collector group, they distribute heat to a large number of circuits and heating devices. At the outlets of the comb, outlet valves of the cut-off or regulating type are placed. They block the coolant or change the supply volume to the circuits. Closing one of the channels allows repairing without disconnecting other consumers.

Additional devices are mounted on the comb body to increase the efficiency of the heating system:

- flow meters;

- air bleed and water drain valves;

- heat meters.

If it is not possible to achieve equality of the heating circuits, they include a circulation pump that equalizes the volume of fluid passage.

With different number of contours

The need for a manifold appears when there are two or more heating circuits. This is convenient for radial piping to create a system of underfloor heating - individually for each heater.

The heating system fits for decades. It is sunk into the floor screed and is not removable. Therefore, the collector group has the ability to block several channels at once. Each circuit in such a system is turned off for repair, prevention, emergency work.

Previously, manifolds were assembled from a variety of tees together with shut-off valves. Now technologies allow to manufacture a product according to the needs of the customer. The finished manifold group consists of two dies with a 1-inch bore diameter. This diameter is used in most cases. Outlets for heating devices - 0.5 ", if necessary, alignment with small diameters are equipped with ¾" adapters.

Prefabricated collector groups come to the market with a number of connection points ranging from 2 to 12.

Collector groups are the centerpiece of a water-based underfloor heating system. The main module of the collectors themselves are mixing units-groups.

In individual housing construction, the units are connected to a high-temperature heating system. A heat carrier with such a temperature cannot warm the floor, otherwise the deformation of the materials will begin, harmful substances will be released from the floor covering, and besides, you cannot walk barefoot. Reduce the temperature by introducing mixing groups. When cold water is added from the return line, the coolant reaches the values prescribed by SNiP - 26 degrees for rooms with a constant presence of people, 31 degrees - with a temporary stay, 35 degrees - along the axis of the bathroom heating line.

Mixing groups are necessary when distributing flows to high-temperature boilers going to heating radiators and for underfloor heating.

Complete pump options

The group mixing unit consists of a control valve and a circulation pump designed for forced circulation of the working medium in heating systems. The more collector groups are assembled, the more powerful the pump is needed.

The Grundfos UPS series pump is operated around the clock in all types of heating systems. The pump speed is regulated in steps. In addition to the underfloor heating, it is possible to connect up to 3 radiators of batteries, so power adjustment is very useful. A similar mechanism works from a household outlet with a voltage of 220 V, is economical, does not make noise. These characteristics are important for use in heating private houses.

With flow meter

Flow meters are an obligatory attribute of the heating system. They are necessary to regulate the flow of the heating medium due to the different lengths of the pipes. Without them, the resistance in short pipes is less than in long ones. This will imbalance the water system. The flow meter creates uniform circulation of the working medium in all circuits of the system.

It is possible to operate the underfloor heating system without a flow meter. But to achieve fine adjustment of temperatures will not work - the inertia of the warm floor is large. You will have to wait for it to cool down to adjust the shutoff valve. With manual adjustment, you will have to remember the position of the valve. The flowmeter is marked.

Sometimes collector kits for underfloor heating with a flow meter cost less than a separate collector with inlet taps.

Valve selection criteria

If the circulating pump regulates the flow rate of the working fluid, then the control valve limits the fluid according to temperature. An autonomous boiler produces a heat carrier with a temperature of 95 degrees. In the heating system, the water is not much colder - 80-90 degrees. The normal temperature of the liquid in the heated floors is 35-55 degrees. The regulating thermostat determines the temperature of the flow of the working medium and gives the command to the valve to open the opening from the reverse stroke. With cool water, the temperature drops. When the temperature in the pipes reaches 55 degrees, the circulation pump is disconnected from the network by a thermostat, after which the volume of the passing heat carrier decreases.

The 3-way valve is a unit with 1 outlet and 2 inlets. The valve plug is opened by a temperature sensor located in the valve.

When choosing a valve, the following indicators are taken into account:

- The volume of the room for heating. Small rooms do not require complex automation units. Balconies, toilets, corridors work easily under the supervision of the simplest devices. Heating large areas requires an automatic valve with a built-in diaphragm opening temperature sensor.

- The volume of the passed liquid. This indicator is determined when writing a project for a heating system. The valve must meet the fluid flow requirements. Otherwise, it will fail.

- Cross-sectional diameter for connection to heating pipes. Adapters are used at different rates.

- Manufacturing material. Quality valves are made of bronze or brass - materials with a small expansion coefficient. They do not change their properties when in contact with a hot coolant.

The three-way valve is a tricky part. It is necessary to choose reliable models from well-known manufacturers. Warranty, specifications, certificate, test report are verified upon purchase.

Before installation, the valve must be checked - the minimum value of the temperature of the control ring is set and a stream of hot water is passed. A serviceable valve must shut off this flow.

Heating of residential buildings with two or more floors involves the use of several water circuits of different lengths.The combination of a three-way valve and a servo drive with a controller allows you to supply hot coolant to a specific room or send it for heating.

Initially, the heating servo is not included in the package. But the presence of a servo motor allows you to adjust the temperature depending on the time of day.

For a valve with an electric motor, the actuators are electromagnets or low-power servomotors.

Collector group with their own hands

Finding a suitable finished product is not always possible. Sometimes it is easier to save money and make a collector yourself from a popular material - polypropylene.

In the calculations of the product, the golden rule must be observed - the sum of the outgoing flows is equal to or slightly less than the incoming ones. Failure to comply with this principle threatens the uneven distribution of the coolant.

Pros of a homemade system:

- taking into account the peculiarities of heating without unnecessary collector elements;

- saving money.

Propylene manifold includes 2 parts:

- The first part takes the coolant from the main pipeline, distributes heat to consumers. In this element, it is important to make the contours independent, overlapping in case of prevention. To do this, just close one of the taps.

- The second part regulates the pressure in each individual circuit. Due to this, the intensity of the circulation of the coolant changes. The efficiency of the heat consumers depends on the correct setting of this option.

The right design will simplify the creation of an efficient collector for specific customer conditions. For correct assembly, a number of parameters of the heating system are evaluated:

- number of heating circuits;

- the number and characteristics of the final equipment - temperature, pressure, power;

- the likelihood of placing additional heating elements;

- number of add-ons - sensors, pumps, taps.

After that, they consider ways to connect the circuits to the collector:

- coolant supply from above or below from electric or gas boilers;

- in the presence of a circulation pump, the connection is made from the end of the collector;

- indirect heating boilers and solid fuel boilers cut in only from the end;

- the heating circuits are supplied from the top or bottom.

The project should be printed on paper and depicted visually. Strict adherence to dimensions and proportions will help to avoid installation errors.

The distance between the manifold pipes is about 20 cm. Smaller - complicates maintenance. Larger - increases the size. We divide the comb assembly technology into stages:

- procurement of materials based on the materials of the project assignment;

- connection of the pipe in accordance with the terms of reference;

- connecting pipes using the right tools;

- thorough cleaning and sealing of joints and seams;

- check of tightness by plugging pipes and supplying water under pressure;

- installation in a regular place after hardening of the sealant and paint.

The comb is easily created by hand. It is important to take seriously the creation of the project, observe the parameters of pipes and assembly. A self-assembled collector will take into account the individual parameters of the system.