When choosing efficient and inexpensive heating devices, you should pay attention to Teplolux underfloor heating. The products of the Moscow Region company "Special Technologies and Systems" are suitable for the climatic conditions of all regions of the Russian Federation, are distinguished by ease of installation and an extensive range.

- Teplolux brand information

- Scope of application

- Types of products on the market

- Types of devices by design

- Product series

- Characteristics of a mobile underfloor heating in the form of thin sheets

- Elements of a standard system

- Installation procedure for underfloor heating

- List of preparatory work

- Installation procedure

- Installation and connection of the regulator

- Final floor screed after installation

- User's manual

Information about the brand Teplolux

The geography of comfort salons includes such cities as Moscow (metro stations Varshavskaya, Teply Stan, Kashirskaya, Medvedkovo, etc.), Reutov, St. Petersburg, Kazan, Vladivostok, Novosibirsk. In total, there are 25 retail outlets where the products are shipped from the factory.

Scope of application

Teploluxe heating systems are distinguished by their quality, durability and long operating period. The products can be used in several places:

- under a ceramic tile covering - for a special adhesive composition;

- in humid rooms - a shielded two-wire braid protects the wires from damage;

- in small and cold rooms;

- in regions with interruptions in gas supply or in its absence;

- in apartments and the private sector as a main or additional heating system;

- during the off-season, when the main heating is turned off, but the room is still cool.

The manufacturer claims that the equipment has a lifespan of about 50 years. The warranty is valid for 20 years.

Types of products on the market

The main unit of the underfloor heating is a two-core or single-core heating cable of various diameters.

Types of devices by design

Several device options are available to consumers:

- Cable systems. Suitable for rooms with complex geometry, they are mounted in a screed 3-5 cm thick. The use of a heating cable is to heat only a cold floor covering or the entire room.

- Mats. They are laid under the tiles, they consist of a cable on a fiberglass basis. Due to the minimum thickness of the glue of 5-8 mm, the height difference is excluded, the heating rate and the uniformity of heat supply are ensured.

- Carbon film. The infrared floor is represented by a carbon fiber heating element inside a lavsan sheet. The design saves up to 70% of energy, but it is not recommended to install it on the outer floors. The kit is represented by IR-film, installation cables, tape and clamps.

A thermal sensor is designed to control communications, which must be purchased separately.

Product series

The electric type of underfloor heating is available in several series.

Teplolux MiNi- ultra-thin mats for rooms with low ceiling heights. Heaters are mounted on a small screed or adhesive. Heating power - 150 W / m2.

Teplolux Standard - cable devices with single-core heaters. They are completed with mounting tape and a tube for the temperature sensor.

Systems Tropix are made on the basis of a two-core fiberglass cable. Suitable for wet rooms. Power of communications - 200 W / m2, thickness - 3 mm. Features of the heating mat of the Teplolux brand of the Tropix MNN series:

- alumina-lavsane shielding to increase resistance to electrical and electromagnetic effects;

- multi-wire type of cores - the risks of breaking contacts are reduced;

- XLPE insulating shell - ensures durability of use.

Reliability of connection of system elements is achieved using a pressed mini-coupling.

Ruler Profi includes 16 items, but the following are popular among Russian consumers:

- ProfiMat. Powerful thermomats connected for the main heating. They are made on the basis of a two-core cable. Tiles, carpet, parquet, linoleum and laminate are allowed as a finishing coating.

- ProfiRoll. Cable sections with installation wire, connection and end sleeves. Two heating conductors are protected by double-layer insulation, shielding. Linear power is reduced for a smaller mounting pitch and to prevent “zebra effect”.

The manufacturer provides a lifetime warranty for the Pro series.

Characteristics of a mobile underfloor heating in the form of thin sheets

The coating of the Express series can be used in suburban conditions, in an apartment or in a private house. The main elements of the devices are a plug, a thin heating cable and a thin felt pad. Due to the design, mobile systems are simply laid under the carpet and connected to the network.

Products are distinguished from the rest of Teplolux products:

- appearance - they look like a small rug with a heater in a protective case and a 2.5 m long mounting wire;

- the possibility of heating rooms in 2.8 m2 - rugs 200x140 cm with a power of 300 W;

- use in rooms with a square of 5.04 m2 - heaters 280x180 with a power of 560 W;

- operation as auxiliary heating during the off-season;

- transportability and compactness;

- ease of care and storage.

It is allowed to install mobile floors under light-pile carpets, lint-free and tufted products.

Elements of a standard system

Regardless of modification, Teploluxe products include heating sections, mounting tubes and sensors. The first ones are made in the form of cable sections with one or two cores, equipped with lugs for connection to the electrical network. Corrugated pipes with a diameter of 16 mm are equipped with plugs, designed for temperature sensors.

The sensor or regulator for warm floor Teplolux is a device with which the temperature and energy values are programmed. The thermal sensor is not included in the system, but users can purchase one of the models:

- TR-115 with a switch, an adjusting knob and a signal diode.

- TR-715. The electronic version, which detects the temperature of the system and the ambient air, switches off automatically at the time of malfunction. All data on the state of the equipment is displayed on the LCD.

- TR-725. With the help of the element, the heating setting is provided at a given time. The parameters can be set for a day or a week. Temperature and other factors are displayed on the LCD.

Sections, mats and films are equipped with regulators.

Installation procedure for underfloor heating

Underfloor heating is laid in several stages.

List of preparatory work

Before installing heating devices, you must:

- Determine the compatibility of wiring and underfloor heating by summing the capacities of all household appliances.

- Set the current limit of the fuses. The system with power parameters from 2 kW must be connected to a separate line.

- Make a layout plan. The cable must be laid according to the scheme, the mat is allowed to be cut into fragments.

- Determine the installation location of the regulator - the optimal height from the heated floor surface, which Teplolux recommends, is 0.8 m. The element is removed from the wall by 50 cm.

- Prepare the base. Installation is carried out on a flat, primed and clean surface.

The cable must not go through thermocompression seams.

Installation procedure

Before installation, you need to turn off the electricity. Further work is performed as follows:

- Calculation of the installation step - from household appliances, walls and furniture you need to retreat 5 cm. The laying step is determined by the size of the sections, multiplied by 100 and divided by the length (indicated in the passport).

- Laying sections according to the plan. The optimal distance between the turns is 80 cm.

The maximum deviation of the step is 1 cm.

Installation and connection of the regulator

To install the regulator, you need to disconnect the mains voltage. Then they work according to the following algorithm:

- Marking and chipping the wall for installation wires and a mounting sleeve.

- Fitting the sensor. The element is placed in a mounting tube near the end, which is closed with a plug. Inside, it should move freely - to check, you need to pull out the cable and put it back.

- Sensor installation. The branch pipe fits into a niche with a bend radius of 5 cm at the wall surface.

- For tightness of fixation, the structure is sealed with a putty mortar.

The open end of the branch pipe with the installation cable is led out to the thermostat - this way it is easier to notice.

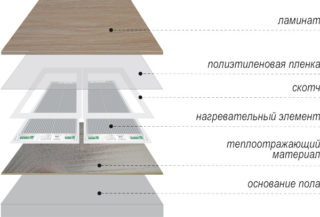

Final floor screed after installation

After testing the quality of the system, the finishing coating is laid. In the presence of materials with high thermal conductivity (tiles, stone), the mats are filled with tile adhesive. The layer should be from 5 to 8 mm. Bubbles are not allowed - the structure may rise.

After the adhesive layer has dried in a draft-free room, the surface is primed. Then the floor tiles with a thickness of 5 mm are laid on glue with a thickness of 5-10 mm. In the presence of carpet, linoleum and laminate, a layer-by-layer scheme is used:

- The base is from below.

- Heating mats or cable sections.

- A mixture of cement and sand (3 cm thick).

- Substrate for finishing.

- Selected finishing material.

In apartments on the ground floor, summer cottages, the following scheme is used:

- Base for coating.

- Thermal insulation layer.

- Sand-cement screed 3 cm thick.

- Heating cable.

- Re-screed 3 cm thick.

- Substrate for finishing coat.

- Decorative floor surface.

When laying thermomats, re-screed is not required - tile adhesive and the coating itself are applied.

User's manual

The Teplolux brand completes the warm floor with operating instructions. The document notes the following points:

- installation only with disconnected voltage;

- turning off the system from the network in the event of a long trip;

- lack of additional coatings on a tiled or stone floor;

- heating mats rolled into a roll cannot be connected to the network;

- mats must be installed on tile adhesive;

- initial start-up and heating takes 6-48 hours.

The test run is carried out only after the final drying of the glue or screed.

Teplolux floors provide additional and basic heating of the room. The systems are characterized by low cost, energy efficiency, heat up quickly and maintain a comfortable temperature in the off-season.