Heating the room is carried out by transferring heat from the coolant to the air or objects in the room. Since direct contact of a heat source or coolant with air is excluded, heating devices act as intermediaries. The latter are classified according to many characteristics.

Varieties of heating devices

The design and efficiency of the heater determines how heat is transferred. This is the main classification of devices.

- Convective - transfer at least 75% of heat by convection - jets. An example is convectors, finned tubes. The source is usually a heating element, heats the air, it is transferred into the room, and already from the warm air masses, surfaces, furniture and people are heated. Appliances can be very effective due to the speed of air heating, but they consume a lot of electricity.

- Convective-radiation - transfer from 50 to 75% of heat by the convective method. These are the majority of traditional heaters: radiators, floor heaters, smooth-tube heaters.

- Radiation - 50% of the heat is radiation. This includes infrared heaters, ceiling and panel heaters. The heater generates infrared radiation, in this case, surfaces, objects and people in the room are heated first, and only then the air. Eliminating air from the heat transfer chain reduces heating costs.

Convective-radiation heaters are installed most often. The devices are highly efficient, cheap and practical.

By type of coolant

The traditional heating system implements the following scheme. The source of heat is a boiler - gas, electric, solid fuel. It heats up a certain volume of the coolant, which enters the system and gives off heat through the surface of pipes and heating devices.

The coolant must meet many requirements: to absorb and give off a sufficient amount of heat, not to cause corrosion, and to heat up to the required temperature.

- Water is the only option for central heating. The reason is the large distances between the heat source and the consumer. Replacing it with any other option increases the heating price tenfold.

- Steam is the so-called dry steam. They are used in vacuum-steam systems, in low and high pressure systems. Plus - the room heats up 3 times faster, there is no risk of pipes freezing. The disadvantage is high fuel consumption.

- Antifreeze - "non-freeze". Glycerin solution, ethylene glycol solution, propylene glycol solution and others. Liquids prevent freezing even in pipes with the smallest diameter. Antifreeze is recommended to be poured into a heated water floor. During circulation, the coolant acts as a lubricant, which increases the service life of pipes and radiators. The disadvantage is the need to match antifreeze to the type of boiler.

- Transformer or mineral oil is a heat carrier in oil heaters. It is a viscous, heat-absorbing liquid that can give off heat to the air in the room for a long time.

It is possible to choose a heat carrier and a corresponding heating device only when organizing an autonomous heating system.

According to technical characteristics

To assess the efficiency of a particular model, it is necessary to analyze the technical indicators.

- Heat transfer is the main criterion. On this basis, the radiation apparatus is better than the convective one. Of the radiators, cast iron is distinguished by the highest thermal inertia, and aluminum is the best for transferring heat.

- Work surface - it is important to consider the total area of the battery, not the number of sections. The calculation of the dimensions of the heater is carried out taking into account the volume of the room.

- Corrosion resistance - ceramic heaters are extremely resistant. Of the metal models, the best are aluminum.

- Pressure resistance - convectors are the most resistant, since there is no such load in them. Of the radiators, the best are cast iron and bimetallic.

- Ease of maintenance - convectors and aluminum panels only need to be wiped periodically. Cast iron and steel must be painted.

- Service life - cast iron batteries last the longest - 50 years. Bimetallic ones have been in operation for 30-40 years. The least durable steel ones - no more than 10-15 years.

Thermal performance is not the only choice. Radiators must meet the requirements of the selected heating system.

Materials for hot water radiators

The most popular heating method is water heating. The source of heat can be a gas, electric, coal boiler, a heat carrier - water or antifreeze, batteries - tubular or panel heaters made of different materials.

Cast iron batteries

This is the most famous type of water heater, adapted to the conditions of central heating. Cast iron batteries are cheap, durable, withstand pressure drops. With a small heat transfer - only 40%, they have a large working surface. Cast iron accumulates heat, so the batteries cool down slowly even after the heating is turned off.

Modern design models are very interesting and beautiful. However, caring for them is difficult.

Steel

It is more often used in the arrangement of autonomous heating, where high pressure or water hammer is excluded, since steel is sensitive to them. The heat transfer of the alloy is higher, it heats up much faster than cast iron. It is easier to regulate heating due to the low thermal inertia. But for the same reason, steel batteries are cooled immediately after disconnection.

The disadvantage is the tendency to corrosion. The heater must be taken care of, clean water with additives must be used for pouring, the surface must be painted.

Aluminum

The maximum heat transfer level is above 70%. The weight of the radiator is small, its installation is extremely simple, it can be installed even on a plasterboard wall. A bonus is a large working surface: the channels along which the coolant moves are placed in sections of a much larger area. Since aluminum conducts heat well, the section heats up very quickly and strongly.

Aluminum is prone to corrosion. To prolong the life, heating radiators, like other aluminum heating devices, are coated with polymer paint.

Bimetallic batteries

The channels through which the coolant circulates are made of steel: it is stronger and more durable than aluminum. The working area of the section is made of aluminum in order to improve the transfer of heat to the air. The bimetallic device combines the advantages of steel and aluminum, but is devoid of their disadvantages, such as a short service life or a tendency to corrosion.

There are also limitations. Antifreeze must not be added to the water used in bimetallic batteries.

The price of bimetallic heaters is the highest and is second only to copper radiators.

Electric types of heaters

Electric heaters work in a different way. The heating medium is replaced by heating elements that function when an electric current is supplied. With rare exceptions, the heating element has a small area. To make the heat supply more efficient, 2 solutions are used:

- pass air streams through the heating device - any kind of convector;

- create a housing with a large working area - panel heaters.

Electric heaters include devices that are a heating element. A heating appliance like Evan's boiler is not. It is a heat source, but not a heating structure.

The main disadvantage of electric heaters is the requirement for the quality of the electric current. If the total power of the heaters exceeds 12 kW, it will be necessary to lay a network with a voltage of 380 V.

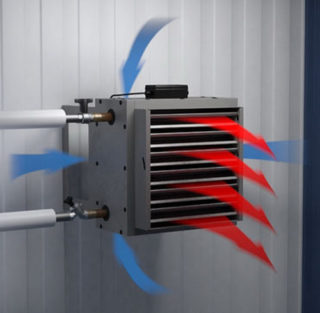

Convection appliances

Heating elements - heating elements, are placed inside a flat case. The surface of the case heats up and transfers heat to the air. However, this mechanism provides only 20% of the heat transfer. There are inlets at the bottom of the appliance. Through them, air enters the inside of the device, heats up and exits through the holes in the upper part. Convection provides 80% heat transfer.

Convectors quickly heat up the room, but do not burn oxygen as much as fan heaters. At minimum temperatures, the appliance can be left on overnight. Power ranges from 0.25 to 2.5 kW. The calculation of the indicator is performed by cubic capacity, since the convector heats the air. Disadvantage - a comfortable temperature is maintained in the room only while the convector is working.

Oil devices

The heating element is a heating element, but the coolant is oil, which is also present. A warm viscous substance fills the sections and transfers heat to the surface. The larger the working surface, the higher the efficiency of the device. Oil-fired electric heating devices are close in efficiency to radiation ones.

Plus - high thermal inertia. The device heats up slowly, but it also gives off heat for a long time after being turned off. This mode of operation is more economical. The devices are produced with a capacity of up to 4.5 kW, but at the same time oil coolers consume less electricity. The disadvantage is a large mass and cumbersomeness.

Infrared heating

The efficiency of the infrared heater is close to 100%. The basis of the device is a film with resistor conductors, carbon spirals and plates, which generate thermal radiation when an electric current passes. At the same time, it is not the air that heats up, but the surfaces, objects and people in the room. Even at a lower air temperature, people in the room already perceive it as comfortable.

IR heaters consume 30% less electricity. Heating is faster than convection. The air does not get too dry and oxygen is not lost.

Gas heating

An efficient and cheap heater, but difficult to maintain. A gas heater or convector works on the principle of a gas oven. Gas is supplied to the burner. The combustion products are discharged to the outside through the chimney. The air entering through the holes is heated in the heat exchanger and flows back into the room.

The power of the heaters reaches 8 kW. Since gas is a fuel available and cheap, heating costs are minimal. There are many disadvantages: you need to install good ventilation in the house, equip a chimney, periodically clean the nozzles. If the device malfunctions, there is a high probability of carbon dioxide poisoning.

Requirements for the installation of heaters

Operational safety is ensured by competent installation of the system. Installation recommendations depend on the type of radiator and the material of execution:

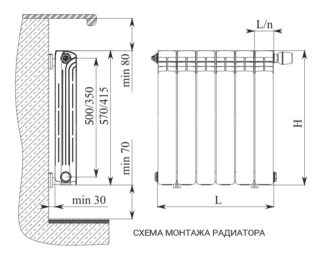

- Batteries of any kind are installed at a distance of at least 6 cm from the floor, 5 cm from the sill boards and 2.5 cm from the wall. In rooms of category A. B, C, the distance to the wall must be at least 10 cm.

- It is better to install heaters under window openings, where they can be accessed for inspection and repair.

- The surface temperature of an open radiator should not exceed +70 C. Otherwise, the batteries are protected by a grill.

- When connecting pipes, parts and radiators made of different metals, threaded adapters made of bronze or stainless steel are used.

- The batteries must be filled with water at all times. The liquid is drained only in case of accidents.

- Heating devices are equipped with shut-off and control valves with some exceptions. The fittings are selected taking into account the type of system: one-pipe, two-pipe, fan-shaped.

The requirements for the installation of gas heaters coincide with the recommendations for the installation of any gas appliances. Build and run by dedicated services only. Convectors and oil coolers are placed in the room, observing the usual fire safety requirements.