The Rinnai gas boiler is manufactured by a Japanese concern for the production of heating equipment. The unit has good technical and operational characteristics, fits compactly into the interior of the room. Technique replaces a person in terms of regulation and control, the choice of the operating mode is made automatically and depends on the pressure of the air-gas mixture.

Description of Rinnai boilers

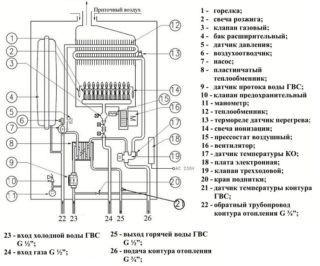

A proportional temperature control module is installed in the design of the equipment. The unit automatically coordinates an advantageous ratio of the gas-air mixture in the firebox. The work is controlled by an electronic microprocessor that includes touch sensors. The technical solution modulates the output power range of 20 - 100% and provides an efficiency of 96%.

The unit operates stably at low pressure in the gas main (from 3 mbar), which is important for consumers. Automatic regulation reduces fuel consumption, increases the operating time of the heat exchanger and other modules, and prevents the appearance of soot and carbon deposits.

High performance is due to the use of a special burner design, which creates the required draft and regulates the gas concentration. Waste combustion products are removed through a coaxial chimney.

The boiler is controlled by a remote control, from which the protection system is configured and self-diagnostics is carried out.

Rinnai boiler series

Each series is manufactured to work in specific conditions. All types of Rinnai boilers from the Japanese manufacturer have similar technical properties, the difference lies in the complexity of the regulation systems and the power of the units.

Available in 4 series:

- RMF;

- EMF;

- GMF;

- SMF.

Boilers are intended for the organization of heating and water heating in the water supply system in private buildings and in production. The equipment runs on liquefied gas and natural fuel from a centralized pipeline. The units have received quality certificates after appropriate tests and meet the requirements for safe operation.

RMF

This version includes double-circuit wall-mounted gas boilers with increased functionality and reduced operating noise. The remote control has a color screen, there is a voice control procedure, sensors for weather changes, freezing and overheating control.

Work parameters:

- the minimum pressure head in the pipes for operation is 205 l / min;

- ceases to function when it drops to 1.5 l / min;

- power 19 - 42 kW;

- heated area 200 - 420 m2;

- expansion tank with a volume of 8 liters.

The power of the units can be reduced by 20% when the heating is switched on, and the temperature of the energy carrier is regulated by the electronic module. The Rinnai gas boiler operates in the intermittent heating mode, and there is always hot water in the water supply system. Installed ECO program for environmental control of work. The series includes models 367, 257, 167, RB-107, 207,307.

EMF

Renight equipment of this series operates on liquefied and mains gas; to select the type of fuel, reinstallation of the injectors is required. The subgroup is characterized by increased environmental friendliness.A minimum amount of toxic combustion products enters the atmosphere, which are removed using a coaxial chimney.

Operation parameters of the units of the series:

- boiler power is 12 - 42 kW;

- minimum consumption of hot water - 2.7 l / min;

- gas consumption from the main line - 1.15 - 4.15 m3 / hour, liquefied resource - 1 - 3.4 m3 / hour;

- expander volume - 8.5 l;

- heating the coolant up to + 85 ° С, hot water - + 60 ° С.

A three-level automation module regulates the intensity of the flame and heating of the energy carrier in the system, depending on weather conditions and the season. Operating errors are diagnosed and displayed in digital and text codes. The electronics coordinate the fan and the air flow for the purge. The series includes models 366, 256, RB-166, 306, 206.

GMF

Functioning parameters of the series models:

- power - 12 - 42 kW;

- stable operation with a drop in gas pressure - up to 4.5 mbar;

- power is regulated in the range of 25 - 100%.

GMF boilers operate reliably on liquefied fuel and have a high efficiency. The burners light up smoothly and turn on less often; soot does not accumulate in the firebox and nozzles.

SMF

The series equipment heats an area of 100 - 400 m2, has 2 heat exchangers. The first is made of copper, the second is characterized by a high process speed and passes through 14 l / min. The turbocharged electric burner smoothly adjusts the air-fuel mixture according to the fuel volume.

Series functioning parameters:

- power - 18 - 42 kW;

- efficiency factor - 90%;

- water consumption in hot water supply - 2.7 l / min;

- heating agent heating temperature - up to + 80 ° С, water - up to + 60 ° С.

The pump is controlled by an electronic control panel. The processor regularly monitors the results of the sensors and gives information to the working modules.

The main features of the Rinnai boilers

The equipment has a separate chimney, a branch pipe and an air intake system, which makes it possible to connect any type of chimney. The design of the burner allows you to adjust the power and determine the economical order of work.

Defense systems warn and monitor:

- clogging of the heat exchanger and chimney;

- stopping combustion;

- overheating of equipment;

- high pressure in the heating main;

- low water level in the circuits;

- defrosting an idle boiler;

- defrosting the heat exchanger;

- electric shock;

- stopping circulation in the boiler.

The unit operates in an open and closed system. In separate rooms, thermostats are installed to regulate the degree of heating. An open rotor pump effectively cools and prevents electrical equipment from contacting water. The magnetic coupling does not require an oil seal and prevents leaks in the pump.

Advantages and disadvantages

The equipment has an additional saving program and a multi-level protective system (10 degrees). The Renai boiler is produced with an original design, it is operated simply using a remote control. The unit provides a uniform, stable temperature of hot water, the degree of heating of the energy carrier is regulated by the environment. It has a long service life without changing efficiency, thanks to quality control at the outlet and an effective control unit in the boiler.

The disadvantages include a large step on the temperature adjustment scale, which sometimes does not allow you to set the required value.

Error codes and troubleshooting

The display shows an alphabetic or numeric designation. The combination corresponds to a specific problem in the equipment operation.Error codes are used to identify breakdowns, improper operation of the processor, incorrect data setting by the user.

Error 99

The numbers light up when there are problems with the removal of combustion products. The error appears on the display when it is difficult to remove smoke from 90 sec.

Initial actions:

- analyze the functioning of the fan;

- inspect the heat exchanger plates, clean them if necessary;

- check the correct installation of the chimney.

Each unit is distinguished by a peculiar device and unique automation, therefore, only a specialist knows numerous features during repair or service. The owner of the boiler should contact the service center if any faults are found.

Popular models of Rinnai boilers

RB-167 EMF is a modification of the previous model, has a power of 18.7 kW and shows an efficiency of 88.3%. Gas consumption - 1.84 m3 / hour. The remote control does not have the ability to set the operating program for a week, there is no frost protection and a weather-dependent mode.

RB-207 RMF (BR-R24) is a popular and well-known model. Heats an area up to 230 m2, assumes feeding two circuits and an efficiency of 86.4%. There is protection against freezing, overheating, a program for selecting a mode for a long period is installed.

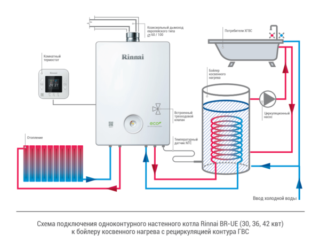

BR-UE30 is a single-circuit wall-mounted model with the possibility of connecting a boiler. The efficiency is 91.7% with a fuel consumption of 2.85 m3 / h and a power of 29 kW. The heat exchanger is made of copper, the burners operate on the turbocharging principle. The body is isolated from noise.

RB-277 CMF is used to connect two circuits, power is 29.6 kW. The efficiency reaches 100%, the gas consumption is 1.84 m3 / h. To eliminate error 99, there is an exhaust fan adjustment.