Window openings are insulated regularly, so the complexity and cost of the procedure matters. Insulation for windows based on self-adhesive tape makes the task easier. The seal is produced from different materials, each type has advantages and disadvantages. Special means can serve as thermal insulation for several years if the work technology is followed.

Variety of types of insulation

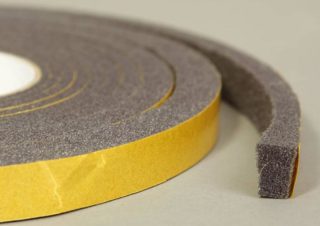

The construction of self-adhesive window insulation consists of an insulating base and an adhesive base. The seal is produced by foreign and domestic companies.

The stores sell brands:

- Profitrast. The belts are made of foamed rubber resistant to destruction from temperature extremes and sunlight. Closed micropores in the structure protect against air and moisture penetration at -50 - + 70 ° C.

- Econ. Products are manufactured with an optimal combination of quality and value. Adhesives are easy to use and comply with Henkel tradition and standards.

- Kimtek. Seals are used for windows made of metal, wood and plastic, there is a choice of the size and type of insulation strip.

- Bison. Prevents drafts, dust and sound. Products do not shrink over time, resists cracking, drying out, mold does not appear on the surface.

- Deventer. The outline is intended for wooden windows and doors. The manufacturing company pays attention to product quality and uses patented raw materials.

- Sanok. Insulation tape is used at outdoor temperatures from -60 to + 120 ° C. The structure of the seal makes it inaccessible to moisture, which increases the thermal insulation characteristics. The material does not oxidize and reacts stably to the action of chemical reagents.

Russian and foreign manufacturers use different raw materials in the production process, the quality of the insulator depends on it.

Foam

The material is a resilient polyurethane foam in the form of a cured foam containing 90% air. Elastic insulation effectively resists heat loss through window gaps and has low vapor permeability.

Properties of foam rubber window insulation:

- does not emit harmful components into the environment during operation under normal conditions;

- when compressed, it is deformed without changing the structure and geometric parameters;

- the weight of the foam rubber is determined by the size of the air cells; in order to insulate the openings, a density of 25 - 35 kg / m3 is used;

- ultimate compressive strength is 120 - 140 kPa, elongation at break is in the range of 245 - 285%;

- under the influence of cold air, the elasticity of the material decreases, but is restored with an increase in temperature, the moisture of the material affects the change in thermal conductivity;

- high-density foam rubber has almost no residual deformation, a seal with low performance quickly breaks down.

The disadvantages of foam rubber include a short service life, since over time the material crumbles, sticks together and loses its elasticity. The insulation emits harmful substances during a fire and ignites quickly.

Polyvinyl chloride

With the help of PVC sealing contours, wooden frames and plastic windows can be insulated. This material has greater strength and durability than foam rubber. The heat insulator is produced using foamed mixtures of resin, rubbers and plasticizers, belongs to the porous types.

Properties of PVC-based insulation tape:

- density is 0.135 - 0.140 kg / m3;

- firmly resists the action of mineral oils, solvents, acids, alkalis, salts, fats, collapses on contact with tetrahydrofuran, cyclohexanone, swells in acetone and benzene;

- works in the temperature range - 15 - + 66 ° С;

- ultimate bending strength - 80 - 120 MPa, tensile strength - 40 - 50 MPa.

The low threshold of frost resistance is a disadvantage of PVC tape. The material has low elasticity and after deformation it is difficult to restore its shape and size, therefore it requires annual replacement.

When heated, the seal releases harmful components into the air. Insulation collapses under the influence of sunlight.

Polyethylene foam

The material is obtained by processing polyethylene under high pressure with the addition of fire-resistant reagents, dyes and hydrocarbon compounds. As a result of extrusion, polyethylene foam is obtained, the structure of which is represented by isolated small voids.

Properties of self-adhesive insulation materials from PES:

- thermal conductivity at the level of 0.0037 W / m · K allows you to qualitatively isolate the cracks from the ingress of cold streams;

- low ability to absorb moisture provides heat-shielding qualities of the material in rainy weather;

- the melting point of polyethylene foam is + 120 ° С;

- the material does not collapse upon contact with various chemical reagents, aggressive media, mold does not appear on the surface and in the mass.

The elastic seal is suitable for use in small crevices, because restores its original size and shape. The polyethylene foam tape seal lasts up to 5 years without loss of quality.

Rubber

Insulation is made on the basis of synthetic rubber by vulcanization of raw materials with the addition of sulfur impurities. Adhesive rubber seals operate at temperatures ranging from -50 ° C to + 100 ° C.

Material properties:

- resists the action of gasoline, oils and other petroleum products;

- for sealing windows, soft rubber is used, which has a density of up to 50 kg / m3;

- does not allow vapors and air to pass through;

- cracks, swellings do not form in the thickness;

- it is distinguished by high indicators of wear resistance in relation to chemical and mechanical action;

- ultimate compressive strength - 5-35 MPa, the material can be lengthened by 100 - 220% without loss of properties.

The service life of rubber insulation is determined by the use of active fillers in the production process and the quality of the raw materials. Window tape is available in round or oval shapes of different diameters.

Characteristics of insulation for windows

Window insulation tape is made on a self-adhesive base or without it. The first type is more often used when insulating openings, because it is easy to install. For the second type, glue is used, which is additionally applied to the surface of the frame to fix the elastic strip.

The disadvantage of a seal without a self-adhesive backing is that the user applies random glue, which leaves hard-to-remove marks on the frame. And the manufacturer of the contour with the base uses a composition that does not leave marks. Labor intensity when installing a self-adhesive window insulation is noticeably reduced.

Advantages and disadvantages

The positive aspects of the application are effective insulation from cold at an affordable cost of the material.The seal can be installed in 2 layers, which increases the quality of protection. The insulation tape simultaneously insulates the room from blowing, noise, moisture and dust.

The contour is put into the installation position quickly, but requires preliminary processing of the gluing points. Without preparation, the tape peels off the surface of the frame when opening a window or sash.

The disadvantages are that not all materials have a low moisture storage capacity. For example, it is better not to put foam rubber on the outer sashes, so that in the rain the seals do not lose their protective characteristics.

Preparation of the frame and glass for insulation

A place is selected for installing the circuit. The tape is placed so that the position of the adhesive base corresponds to the plane of the frame glass. The seal is attached to the part of the opening where the transom is pressed. Double insulation is practiced, when one tape is glued to the frame, and the second is placed on the sash clamping strip.

Preparation procedure:

- the remnants of old material are removed, the surface of the frame and transom is cleaned in the places where the seal is installed;

- if the tape is glued at the junction of the frame and glass, the glass and the contact section of the sash are cleaned;

- the surface is degreased with alcohol to increase adhesion.

For small gaps, a thin seal is purchased, and large gaps are protected by thick and wide tapes. The perimeter of the installation places is measured, depending on this, the total footage is taken.

Diy window insulation installation instructions

The length of the piece is measured with a tape measure and cut off from the roll. The protective layer is removed from the tape gradually, as it is glued. It is impossible to simultaneously clean all the pieces of the protective coating, because the sticky layer will become dusty or dry. The tape is pressed against the surface, no additional use of a hair dryer or roller is required.

The next pieces are measured and cut after fixing the previous sections. The seal is glued without tension, at the corners the tape can be wrapped, not cut off. The work is carried out in the fall, when there is no strong cold outside, which negatively affects the process. The drying time of the glue is 2 hours, after which the flaps are closed.