Home heating with a floor-standing water circuit is becoming more and more popular in the private sector and in commercial construction. Thanks to the installation of these systems, it is possible to create the most comfortable and safe temperature regime in the room. To properly close the warm floor in the house, you need to take into account many aspects related to the further operation of this structure. Properly selected material heats up well, while maintaining its appearance, volume and performance. Before making the optimal decision in all respects regarding the choice of coating for a warm water floor, it is necessary to study the requirements for it, features, pros and cons of the materials on sale.

Performance characteristics of coatings

In country houses and dachas equipped with autonomous heating, preference is given to water circuits, since these systems consume much less energy than electrical ones, it is safer, the risk of a critical temperature rise is eliminated. Subject to competently performed and carried out installation, the structures are reliable and durable. However, pipes embedded in concrete, through which hot water runs, are only part of the system that is a carrier of heat. It still needs to be transferred to the room with minimal losses. For this, the finishing coat is laid for a warm water floor.

When choosing a material, it is necessary to take into account the following criteria:

- Thermal conductivity. This indicator determines the ability of a substance to transfer heat, the rate of its heating and cooling. The higher the coefficient of thermal conductivity, the better the bodies conduct energy through themselves and the less its loss. If the tile has KT = 1.05, almost all the heat produced by the circuit is transferred to the room. If KT = 0.04, in order to warm it through and through, you will need to spend a lot of energy, most of which will be absorbed by the material.

- Coefficient of thermal expansion. It can be zero or as high as a few percent. When choosing a flooring for a warm floor, you need to abandon materials that have an indicator of more than 0.5%. Otherwise, bulging and cracking may occur.

- Environmental Safety. It should be borne in mind that most synthetic coatings change their structure when heated and begin to release substances harmful to human health into the air. Such decking must be resolutely discarded.

- Mounting method. If the work will be done by hand, you need to evaluate your strengths and capabilities before taking on it. If a choice is made in favor of a film heater, it is advisable to choose a collapsible coating option.

When choosing a coating for a warm water floor, it is necessary to take into account all the nuances in order to ultimately achieve an optimal result in all respects.

Underfloor heating technology

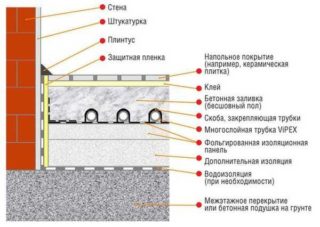

The warm floor is a multi-layer structure, where each level has its own task.

This structure consists of materials that are usually laid in the following sequence:

- Waterproofing. Designed to protect against moisture coming from the bottom and from possible leaks. Lubricating and roll materials are used.

- Thermal insulation.The energy of the circuit must go up, and not into the floor slab, which is the basis for the pipes. Solid slabs or ready-made shaped blocks with grooves pre-cut for communications are used.

- Water circuit. It is made of iron, copper and metal-plastic pipes. Depending on the size and configuration of the room, communications are laid in a spiral or snake. One room can have one or several circuits.

- Screed. It is poured with concrete mortar with a thickness of 3-5 cm. Inside it contains a reinforcing cage to give the slab strength and resistance to deformation.

- Finish coating. Performs the functions of transferring heat energy and decorative parts of the interior.

The technology for manufacturing a warm floor is the same for all types of premises. The only difference is the surface cladding.

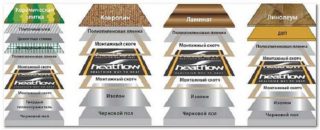

Installation materials

Each apartment and private house consists of premises that differ in purpose and operating conditions. Before laying the finishing coat on a warm floor, you need to assess the humidity, permeability and style of room decoration. If ceramics are perfect for the kitchen, then not everyone will decide to put it in the bedroom. However, with the will and persistence, you can find a great solution for any circumstance. To do this, you need to familiarize yourself with the intricacies of choosing a topcoat.

Tile

On sale are products from porcelain stoneware, glass and ceramics. Possible options for classic styling, pattern and mosaic. The tiles are laid on a special waterproof cement-based adhesive. A layer of mortar with a thickness of up to 3 mm has practically no effect on the performance of the coating.

Material advantages:

- strength;

- wear resistance;

- the highest thermal conductivity in comparison with other types of finishes;

- attractive appearance;

- durability;

- environmental Safety;

- waterproofness;

- immunity to mold and mildew;

- resistance to temperature changes, low coefficient of thermal expansion;

- wide range of colors and textures;

- ease of cleaning from dirt.

The tiles also have disadvantages. The coating is slippery and can fall on it even if it is dry. In addition, ceramics and adhesives place additional stress on the supporting structures.

Not everyone likes tiles in the nursery and living room. You can solve the problem with visual perception by laying a texture material that imitates natural wood.

Linoleum

This option is very popular among budget housing owners. Linoleum is laid directly on the concrete base and fixed on it with special glue. For the topcoat, rolls without an insulating backing should be purchased. It is advisable to choose coatings from natural raw materials (marmoleums) or PVC, which do not emit harmful substances.

Material advantages:

- a large selection of sizes and patterns;

- affordable cost;

- ease of installation;

- waterproofness.

The main disadvantage is that linoleum is easy to tear with a hard and sharp object. Even a small amount of moisture makes the coating slippery. Solvent accidentally splashed on the floor will stain it.

Laminate

For laying on a warm substrate, it is necessary to use a laminate specially designed for such purposes. The thickness of the coating should not exceed 8-10 mm. Such a product is labeled to indicate its ability to withstand temperature extremes.

Material advantages:

- good thermal conductivity;

- presentability;

- ecological purity of quality products;

- ease of installation;

- the possibility of dismantling.

Laminate is afraid of water. The price of goods from a trusted manufacturer cannot be called affordable.

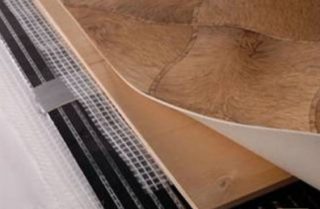

Parquet board, parquet

It is advisable to lay wooden parquet on an infrared film, since the natural substance does not transmit heat well. If it is impossible to refuse such a coating, you should choose products made from dense varieties of wood.

The board as a topcoat has the following advantages:

- presentable view;

- ecological cleanliness;

- pleasant sensations when touched;

- ease of installation.

The disadvantage of parquet is that it does not tolerate changes in temperature and humidity. Based on this, significant costs arise for the purchase of expensive and high-quality coverage.

Carpet

The decision to cover with carpet will pay off if it will lie as a finish on a rough wooden floor. Laying on a concrete base is not desirable - thick material is soft, but absorbs heat, thin material conducts it well, but walking on such a surface is hard and uncomfortable.

Advantages of carpet:

- affordable price;

- a large selection of texture and composition;

- ease of installation;

- resistance to dampness;

- nice view.

It should be borne in mind that cleaning carpet, especially wet, is associated with a certain difficulty. It takes a lot of energy to warm it up.

Cork covering

Cork is a practical building material that combines the functions of a decorative finish and a heat insulator. The second criterion must be considered when choosing this type of flooring.

Plugs of cork:

- ecological cleanliness;

- presentability;

- resistance to dampness;

- durability;

- ease of installation;

- no thermal expansion.

Taking into account the low thermal conductivity of the cork, it is allowed to lay a coating with a thickness of no more than 4 mm on a concrete base. It should be borne in mind that such a finish is easy to damage with hard and sharp objects.

Calculations of the selected room

The calculation of the power of the water floor is done with reference to the selected topcoat. The parameters of the temperature generated by the circuit should correspond to the thermal conductivity of the upper trim. The cork requires a minimum power of 300 W / m² of floor. To warm up linoleum with high quality, 120-150 W / m² is enough. When using wooden parquet, a power of at least 300 W / m² is required to achieve comfortable conditions. The least energy is required for tiles - only 100 W / m².

The best choice is the combined use of all types of coating for the arrangement of premises for various purposes. This will allow you to achieve a combination of the optimal level of comfort, coziness and style.