An effective way to maintain a comfortable microclimate in a home is to plaster the facade over insulation. A protective material without external finishing has an ugly appearance and is destroyed by precipitation and temperature changes. Plaster layers are made of various types, differing in properties and technical characteristics.

Technology advantages

The facade gives the impression of the architectural style of the building and belongs to the representative part of the house. External wall decoration for insulation protects the home from wind, moisture, precipitation compared to internal thermal insulation. Facade plastering moves the point of condensation to the outer surface, and moisture evaporates in the atmosphere, and not inside the room.

Exterior cladding reduces the risk of cracks in the load-bearing wall and extends the building's lifespan. Thin-layer finishing improves the internal microclimate and enhances the aesthetic perception of the building. Visual defects are covered with decorative cladding.

Advantages and disadvantages

The plaster forms a protective layer that stops the deterioration of the insulation. Wet finish withstands temperature fluctuations and is not damaged by frost.

The material has advantages when performing work on technology:

- does not collapse under mechanical stress;

- allows steam and condensate to pass outside;

- additionally protects against noise.

In the passages, a metal mesh frame is installed before plastering to prevent chipping.

The process is laborious and requires professionalism in application. Textured plaster takes extra time. Work performance depends on the air temperature (not lower than -5 ° С).

The choice of insulation

The material is sorted taking into account cost, durability, insulation qualities.

The type of external wall is taken into account:

- for fences with low thermal conductivity (gas silicate, aerated concrete), mineral wool mats are used;

- porous walls (wood, coarse-grained slag or expanded clay concrete) must be insulated with insulation with the possibility of air passage, for example, fiberglass with hydrophobic impregnations;

- for brick, concrete, a layer of foamed polymers is used.

The thickness of the layer depends on the type of material, this parameter affects the reduction in the cost of building insulation.

Expanded polystyrene

Lightweight boards are water-resistant, do not get wet under the influence of moisture and retain their integrity. The insulation layer does not allow steam to pass through, it has a high density. Penoplex contains fire retardant flame retardants, so it self-extinguishes when ignited.

Negative qualities include:

- the release of harmful components when heated;

- destruction by the sun;

- damage from contact with bitumen and similar substances.

Extruded polystyrene foam, which is of high quality, works effectively for insulation.

Mineral wool

Thermal insulation for mineral fiber plaster lasts for a long time. The mats have different fiber structures and are resistant to heat and chemicals.

The material is produced in 3 types:

- glass wool - from molten glass;

- stone wool is produced by melting sedimentary rocks;

- slag wool - melt of the remains of a blast furnace.

The vapor-permeable layer repels moisture well if the composition contains hydrophobic additives. The material belongs to environmentally friendly species. For convenience, it is produced in two layers with a dense outer and loose inner surface.

Tools and equipment for work

To organize the automatic application of material to the facade, plastering units or stations are used. The dry mixture is poured into the hopper, and water is also supplied there. The solution is delivered to the surface by means of injection hoses with a tip. In the process, rules, trowels, spatulas are used.

The technology of plastering on the facade insulation by the manual method is different and requires the use of tools:

- falcon for delivering mortar;

- ladle, shovel, scoop for spraying;

- trowel, trowel - solution distribution;

- grater - smoothing and grouting;

- level - quality control.

A corner trowel is used to level the inside and outside corners. The solution is prepared in special tubs made of metal or plastic.

Types of plaster

A distinctive feature of the finish is that the plaster on the insulation creates a uniform seamless coating over the entire surface of the wall. The technology does not require special fasteners that create cold bridges to weaken the thermal insulation qualities of the insulating layer.

Various application technologies are used to create an attractive decorative finish. Materials have different qualities.

Mineral

Cement, sand and active additives form the basis of the composition, pigments are introduced into the finished mixture during application. Mineral plasters are durable, but cannot withstand strong liquid pressure, for example, when washing a facade with a liquid under pressure. Technological additives are used to reduce water permeability.

The material is packed in bags in the form of a dry mixture, which is diluted with water at the workplace. Mineral compositions are among the popular types due to their relative cheapness. Fungi and microorganisms do not grow on the surface of the finish. The disadvantage is the small selection of colors.

Acrylic

The plaster contains mineral components based on acrylic polymer resins in the form of an aqueous solution. The surface layer is elastic and lasts a long time without loss of integrity. Requires regular cleaning, as acrylic accumulates dirt and attracts dust.

Acrylic material for facade decoration is sold ready-made in plastic containers. The coating belongs to vapor-permeable types, so the wall gives off excess moisture to the atmosphere, there will be no dampness in the rooms. The additives in the composition protect against microorganisms.

Silicate

This material is located between acrylic and mineral plasters. The composition is based on liquid glass or potassium silicate. Acrylic resins are added for flexibility. Mineral components in combination with glass fibers create a coating of medium strength and elasticity.

The mixture is sold in polyethylene containers and is ready to use. The advantages include high vapor permeability without the ability to retain moisture inside. The material does not accumulate static electricity, the final finishing is carried out by painting.

Silicone

The finishing layer creates a coating with high elasticity, while withstanding the shrinkage of the building without collapsing. The silicone coating of the facade is self-cleaning during operation and does not attract dust. Dirt is removed by rain or wind.

Water vapor permeability is low, but it is at an acceptable level for partial removal of internal moisture. The disadvantages include the high price. The topcoat is made with polymer paints.

Stages of plastering the facade on insulation

Facade plaster corresponds to the declared qualities, if applied according to the technology. In the process, surface preparation is carried out, and drying time intervals are observed for each stage. So you can insulate the wall and avoid regular facade repairs in the future.

Preparatory work

The wall area is cleared of layers, protruding mortar, irregularities are knocked down. Cracks on the surface deepen, wetted with a primer and filled with repair mortar. After drying, the surface is cleaned.

The total area of the facade is primed to increase adhesion to the insulation and create a protective film. Drying time is 24 hours.

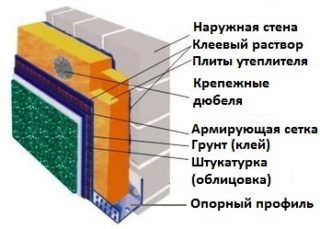

Insulation installation

The method of fixing the insulating layer depends on the type of insulation. For mineral mats, a galvanized profile frame is required to support the loose material. Additionally, dowels with wide heads are used for wall mounting. OSB sheets are nailed along the frame for applying a plaster layer.

Insulation panels, such as polystyrene foam, extruded polystyrene foam, are attached with glue. The composition is applied to the back of the panel and pressed against the wall surface. Dowels-fungi are used in the same way. The glue dries for 24 hours, after which the plaster is applied.

Facade reinforcement

A reinforcing pad is placed on the surface to prevent cracking during operation. The layer is fastened over the area using hardware, for example, from metal. If the pre-layer is thick, the mesh is sunk into it.

The plastic mesh is fixed with plaster. The edges of adjacent layers overlap each other by at least 10 cm. The layer is laid so that folds do not form. Perforated corners made of galvanized or plastic are placed on the corners of the building and on the slopes of windows and doors.

Plastering

The first layer (spatter) of mineral plaster is applied with a trowel, then it takes a while, and a priming layer is made with a liquid solution. A wide trowel or spatula is used. Coating is carried out on a hardened but damp surface that has not yet dried.

Silicate and silicone compounds are applied in 1 - 2 layers, while the alignment is performed simultaneously, and the grout is done after hardening. Finally, the surface is painted in the selected color.