A feature of stove heating is a large amount of heat released into the atmosphere. You can reduce the cost of buying firewood and coal by installing a heat exchanger on the chimney pipe. Specialized stores offer recuperators suitable for different operating conditions. Simple devices are made by hand.

Purpose of the device

Up to 40% of the heat released during fuel combustion in furnaces does not fulfill its purpose. By means of draft, hot gases enter the atmosphere through the chimney. In this case, the metal drainage channels are very hot.

The recuperator housing, which does not heat up so much, protects against burns if accidentally touched.

Using a heat exchanger, part of the energy is used to heat air, water or antifreeze in the heating system.

Work principles

Only a heat exchanger installed on a metal pipe is considered effective. The outer surface of brick chimneys does not heat up above 40 degrees, so you cannot get a lot of heat from them.

The device operation algorithm is simple:

- hot gases passing through the pipe heat it up;

- from the outer surface of the chimney, heat is transferred to the coolant - water, air, antifreeze;

- the coolant gives off heat to the room.

Recuperators of various designs transfer heat energy from the combustion products to the coolant.

Manufacturers and retailers divide apparatus into two types depending on the physical environment that transfers energy: air and water. The devices use natural and forced circulation of the coolant.

Air heat exchangers

The work uses the principle of convection.

There are several types of devices.

- The flue gas stream is split and rises through several tubes. Large surface area speeds up heat transfer processes.

- Several pipes are welded to the main channel. Due to convection, the air in the room passes through the heat exchanger, warming up, rises through the tubes.

- A larger diameter pipe is installed around the main one, to which the supply and output channels are attached. With the help of the device, you can heat the rooms adjacent to the one where the stove is located.

- Metal ribs are welded to the central tube, forming channels. In this way, the area involved in heat exchange and accelerating convection is increased.

- A variant of the bell-type furnace. Hot gases rise through the heat exchanger and heat the air. While cooling, the vapors descend down the hood and are discharged into the atmosphere.

Commercially manufactured air heat exchangers are readily available from specialist retailers. Products are produced with standard fit diameters. Install such devices instead of one section of the chimney.

If the chimney is made according to non-standard dimensions, the heat exchanger for the chimney can be easily made by yourself. Work within the power of any home craftsman.

The price of factory fixtures is high - this is the second reason in favor of making a heat exchanger on your own.

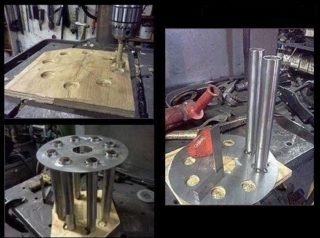

To work you need tools:

- welding machine and protective mask:

- angle grinder (grinder) with cutting and grinding wheels;

- drill with a set of drills and crowns for metal;

- tape measure, ruler, protective equipment (gloves, glasses).

Depending on the chosen design, metal strips or corners, steel plates are selected from available stocks or purchased.

It is undesirable to use galvanized steel for work. When heated to high temperatures, harmful zinc compounds are released into the air.

Simple homemade designs

The simplest and most affordable option for an air heat exchanger for a chimney is the ribs welded to the main pipe. The work will take no more than an hour.

Suitable material:

- pieces of a corner or plate made of metal;

- shaped or round pipe.

The whole process consists in cutting parts of the same length and welding them to the chimney pipe.

The heat exchanger should not "take" all the unused heat - condensate and carbon deposits form in the insufficiently hot pipe, and the draft decreases.

Limits the use of homemade models unattractive appearance. If design solutions are not required (garage, workshop, sauna), the models successfully cope with the task.

For more complex options, when the gas flow is divided into several tubes, it is necessary to have the professional skills of a welder - a carbon monoxide leak through uncooked places is deadly, the smoke will not allow you to comfortably stay indoors.

In cases where neat and beautiful designs are required, it is better to contact trade organizations and purchase a finished product.

For the manufacture of nickel-plated parts or stainless steel heat exchangers, you will need expensive material, work skills and special equipment for spot welding.

Water models

In water heat exchangers, the medium for transferring energy from the pipe is liquids - water or antifreeze in heating systems or clean water for household needs.

There are two designs:

- in the form of a coil connected to a storage tank;

- "Samovar" designs.

In the first case, several turns of a copper, aluminum or stainless tube are wrapped around the pipe, which are fed to the accumulator.

The coil can be in the air or inside an additional tank. The second option involves a sealed container located around a metal chimney. The unions for the supply and discharge of the heated liquid are welded to the tank.

The water heated in the heat exchanger, due to the laws of physics, rises into the external storage tank. Be sure to arrange a circulation circuit. If it is not done, the water heating up will rupture the recuperator.

Warm water is taken from the tank. A drain valve is needed to remove water if the room is not constantly heated. At negative temperatures, defrosting of all parts of the structure can occur.

Having added a circulation pump and a safety group to the circuit, one, maximum two heating radiators are connected to the heat exchanger. This design is sufficient for heating a one-room room.

The heat exchanger of a solid fuel stove will not heat a country house. Large heat removal leads to cooling of the pipe and a decrease in draft.

How to do it yourself

The manufacture of "samovar" designs is trusted by professionals or the finished product is bought in a store.

To avoid leakage in the seams, you need skills in welding.

Metal is cooked by gas welding - electric welds are unsuitable for long-term operation in systems filled with liquids.

A heat exchanger in the form of a coil for hot heat supply is independently made.

Of the materials you will need:

- copper or aluminum tube up to 25 mm in diameter;

- a tank with a float mechanism for supplying liquid from the water supply pipeline;

- flexible eyeliner;

- ball valve.

The total length of the tube for natural water circulation should not exceed 3 meters.If the part is longer, a circulation pump is installed in front of the heat exchanger.

Sequence of work:

- At the ends of the tube, threads are cut to connect the fittings.

- The pipe is wound around the shape of the same radius as the chimney. If the cross-section of the tube is small, it is filled with sand. This will prevent creases and overlaps of the inner section.

- Install the finished coil on the chimney.

- The heat exchange tank is hung on the wall, but not higher than 50 cm from the hot water outlet from the coil.

- Make connections.

Simpler in execution, but more expensive is the option when a flexible corrugated stainless tube is used for the manufacture of the spiral. Buy a corrugation with already mounted fittings. This will facilitate installation; you do not need to purchase special tools to install the connectors.

A chimney heat exchanger purchased or made by hand will save money on the purchase of fuel and add comfort to a country house, a bathhouse, a garage. Devices pay off quickly, and homemade ones are inexpensive. Installation does not require great skills, while the benefits of the device are great.

I had a chance to arrange air heating in a house for seasonal use, built from a bar with a thickness of 150 mm. A fireplace with a cast-iron firebox TARNAVA, with a capacity of 17 kW, was built as a heat source. It was necessary to heat three rooms - a fireplace room and two adjoining bedrooms. What I've done ? In the heat chamber of the fireplace, I installed two air ducts, which I brought through the wall into the bedrooms, where I installed duct fans on them. When the fireplace is fired, hot air from the heat chamber (from its upper zone) is captured by air ducts and forced into the bedrooms, into the lower zone. In an hour it's already warm there! The fireplace room is heated by the firebox itself and through the convection grate in the heat chamber.

It's nice to see that someone started saving gas, the idea is great, but the trouble is, OAGV manufacturers talk about 95% efficiency, they lie right off the bat. Indeed, 30% of the heat flies into the pipe and your measurements are approximately correct, because the gas burns at 400 * C, the heat flow needs to be cooled, only the heat exchanger should be more efficient and here you can remember the heating column or place more corrugations around the turbulator with passage ribs along the edges of the pipe

you need to insulate the collector and the mains and here's the savings and not do nonsense