The classic control valve for heating is an integral part of the piping that works as part of boiler equipment. The range of these products and the functions they perform have only increased over the years. Having familiarized yourself with the existing varieties of control valves for heating radiators, the user will be able to choose the most suitable option for himself.

Control valve functions

According to the generally accepted classification, the control valve for heating refers to the elements of shut-off valves included in the piping of the system. Its main purpose is to open and close the channel for the passage of the coolant directly through the batteries. Modern requirements for the arrangement of the piping prescribe the mandatory equipping of heating systems with locking elements of various types.

Their presence makes it possible to shut off the movement of the coolant in an accident and perform troubleshooting operations without removing the liquid from the pipes. In addition, due to the limitation of the volume of the circulating medium, it is possible to maintain a comfortable temperature distribution in a private house or apartment.

Regardless of the type of heating system, the ability to control heat flows allows you to reduce the flow rate and balance the pressure distribution in it. In addition, adjusting elements are used in special devices responsible for maintaining a fixed temperature level.

Types of control valves and their parameters

The types of special shut-off valves for controlling the supply of heat to the radiator include:

- regulators made in the form of valve mechanisms with thermal heads, setting a fixed temperature;

- ball valves;

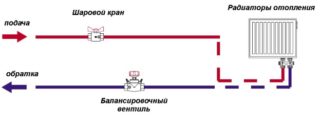

- special balancing valves, manually operated and installed in private houses - with their help it is possible to evenly heat the interior of the house;

- bleed air valves - Mayevsky's manual mechanisms and more advanced automatic air vents.

The list is supplemented by sample valve regulators used for flushing batteries and draining water. The same class also includes a check valve that prevents the movement of the coolant in the opposite direction in networks with forced circulation.

The indicators characterizing the operation of any type of shut-off valves include:

- standard sizes of devices by which they are matched to specific types of radiators;

- pressure maintained in operating modes;

- limiting temperature of the carrier;

- product throughput.

For the correct choice of a shut-off valve, it will be necessary to take into account all parameters in aggregate.

The principle of operation of heating taps

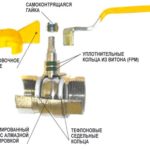

The principle of operation of the crane is more convenient to consider using the example of a ball valve. To control it, it is enough to turn the lamb by hand. The essence of such a mechanism is as follows:

- When the crane handle is mechanically turned, the impulse is transmitted to the shut-off element, made in the form of a ball with a hole in the middle.

- Due to the smooth rotation, an obstacle appears or disappears in the path of the fluid flow.

- It either completely blocks the existing passage, or opens it for the free passage of the coolant.

It is not possible to regulate the volumes of liquid entering the batteries using a ball valve.

A valve that allows you to do this, in its principle of operation, differs markedly from a spherical analogue. Its internal structure allows for smooth closing of the passage opening in a few turns. Immediately after changing the balancing, the valve position is fixed in order not to accidentally violate the device settings. As a rule, such taps are installed on the radiator outlet pipe.

The assortment of valve products includes samples with extended functionality, which allow for additional possibilities for adjusting the coolant flow.

Installation and adjustment of valves

When installing non-adjustable ball valves, simple schemes are used that allow them to be freely placed on polypropylene branches from the riser even before they enter the batteries. Due to the simplicity of the design, the installation of these products is possible on our own. Such shut-off valves do not need additional adjustment.

It is much more difficult to mount valve devices at the outlet of heating batteries, where flow volume adjustment is required. Instead of a ball valve, in this case, a control valve is installed for heating, the installation of which will require the help of specialists. You can do this on your own only after carefully studying the installation instructions.

Depending on the layout of the devices and the distribution of heating pipes, it is possible to select a special angular valve suitable for radiators with a decorative coating. When choosing a product, attention is paid to the value of the limiting pressure, usually indicated on the case or in the product passport. With a small error, it should correspond to the pressure developed in the heating network of a multi-storey residential building.

It is advisable to adhere to the following recommendations:

- For installation on radiators, you should select high-quality taps made of thick-walled brass, forming a connection with a union nut - American. Its presence will allow, if necessary, to quickly disconnect the emergency line without unnecessary rotational operations.

- On a single-pipe riser, a bypass will need to be installed, installed with a slight offset from the main pipe.

The issue of installing a balancing type valve, which requires special adjusting operations, is even more difficult to solve. In this situation, you cannot do without the help of specialists.

Popular models of control valves

Among the well-known models of controlled valves, products from the following companies stand out: Honeywell (USA), Valtec and Itar (both from Italy).

The first place in unofficial ratings is confidently taken by the Italian manufacturer Valtec, which is explained by the high quality of the products offered. The latter are made not from the usual silumin, but on the basis of CW617N sanitary brass. Ball valves from this company work well in the temperature range from -30 to +150 degrees. In the event of a breakdown, the structure is easily restored, for which it is enough to replace the stem and its seal. The service life of these products is at least 25 years. The advantages of Valtec cranes include:

- the presence of models with half-grips in the configuration;

- the ability to select corner samples;

- a wide range of colors;

- wear-resistant polymer seals.

Their disadvantage is the high cost and the impossibility of replacing the ball and seals.

This is followed by products from the Italian manufacturer Itar, the advantages of which include the use of ISO 9001 quality standard in production. Thanks to it, the company has launched the production of ball valves in almost 100 countries around the world. The advantages are manifested in the use of modern technologies in the production, completely excluding marriage due to human fault.The disadvantages of these products include a small selection of connection diameters and the availability of only red levers in the range.

Honeywell valves feature a hardened brass body. For connection to pipes and batteries, they are provided with an internal thread. All products are carefully tested after assembly and are designed for an operating pressure of 16 bar. The ball mechanism of the product is started not by turning the lever, but under the action of a special electric valve. Such a device allows you to control the valve remotely (from the remote control) and simultaneously control several channels for supplying water to the system.

The advantages of these models include:

- relatively low cost;

- high quality seals;

- the ability to work at coolant temperatures from 2 to 130 degrees.

These products have one drawback - they can only be mounted on strapping equipment with an external thread.