For an autonomous heating main of a private house or a bath, a stationary stove is used. Due to the high heat transfer and efficiency, a comfortable temperature is quickly generated. To reduce the cost of arranging the system, a boiler in a heating furnace can be made independently.

The need for boiler equipment in a heating furnace

When fuel is burned in a furnace, useful heat is directed into the air or escaped through the chimney. In some cases, a low-power heating unit is not enough for effective heating of the coolant. Furnace boilers are justified for several reasons:

- full heating of distant rooms - no need to connect additional electrical appliances;

- creation of a thermal curtain - windows do not sweat, the house does not undergo rotting processes;

- improvement of circulation inside the heating system - the temperature difference remains in different sections of the coolant;

- elimination of corrosion on the metal parts of the furnace.

You can combine stove heating with radiator wiring in the house using a boiler built into the heating or hob.

Making a heat exchanger with your own hands

It is allowed to build in flat, air and tubular heat exchangers with your own hands. When constructing a device, it is necessary to take into account the labor costs and the cost of the project.

Simple adaptation

The flat heat exchanger increases the efficiency of the stove and is installed vertically or horizontally in the boiler. It is easy to remove soot and soot from the element, and due to its large volume, it can be adapted to the needs of hot water supply.

The plate recuperator looks like a large diameter pipe with a smaller one inside. Water moves along it in a heated state, the cooling process takes place in a large pipe.

With our own hands, the structure is made of copper pipes. One should be larger than the other by 4 mm in diameter. The work is carried out as follows:

- Fastening by welding a side tee on both sides of the tube from the outside.

- Installation of a pipe with a smaller diameter.

- Welding the element to the ends of the large tube in a pre-fixed position.

- Installation of short pipes at the outlet to the tees. They are needed for the movement of the coolant.

- Connecting parts with segments with alternate welding of tees to the side parts in the form of a snake.

Steel tubes should be larger than copper ones; assembly is carried out in blocks.

Complex recuperator

A heat-exchange type boiler for stove heating looks like a container with nozzles and a heater. It consists of two sectors with mutual heating. The coolant circulates, falling into the closed circuit of the tank, heats up to 180 degrees. The water is directed into the main line after passing through small pipes.

To weld the heat exchanger yourself, you will need the following materials:

- ready-made tank with a capacity of 90 to 110 liters;

- sheet steel 2.5-3 mm thick, if the tank is made by hand;

- anode;

- 2 copper pipes up to 4 m long for heating elements;

- a device that regulates the heating power.

Before starting work, you need to make a drawing of the finished product, and then start assembling:

- Place the tank at a height of 1 m from the floor and 3 m from the oven.

- Make two holes on the right side of the stove and at the top left.

- Bring the outlet for hot water appliances from below, tilting it by 2-3 degrees.

- Connect the upper branch in the opposite direction with an inclination of 20 degrees.

- Cut in the bottom outlet of the outlet 2 drain valves - for the tank and for the system.

- Seal the holes hermetically for even heating of the rooms.

- Bend the copper tube into a spiral.

- Install the finished coil in the tank, bring the ends out and fix them.

- Attach threaded fittings to the end of the coil.

- Connect the ready-made power regulator to the pipe.

- Put the power terminals on the thermostat, and then the wires.

- Install an anode to prevent wear of the tank from temperature fluctuations.

- Seal seams and all parts with a special agent.

The finished heat exchanger is filled with water and checked for leaks. If everything is in order, the boiler for the stove can be put into operation.

Creating a heating wiring diagram

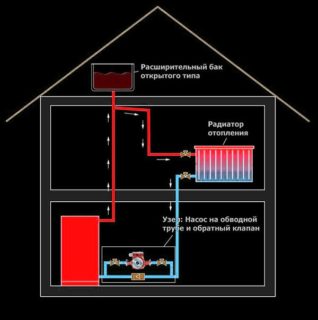

It is possible to combine the stove with a water heating boiler and connect the circuit to the heating system in two ways.

Open system

The coolant moves in a gravitational way, therefore, the installation of a circulation pump is required. It is placed on the bypass, reduces the temperature difference between the return and supply, increases the speed of water movement and the quality of heat transfer. Without electricity, the line will operate on a gravity basis.

To organize it, you will need to increase the line and horizontal inclined in diameter. The open system is equipped with a 32 mm spreading manifold with a slope of 3 to 5 mm for each running meter. The expansion tank is at the top, it receives air from the communications.

Closed system

The radiator network provides for the forced movement of water. The thrust in this case is created by the pump. It also builds up pressure from 1 bar for a cold heat carrier. The reservoir is of the membrane type, located at the bottom. A shut-off valve is used to connect it to the line. Safety devices (air vent, pressure gauge, drain valve) are mandatory.

It is better to connect an autonomous boiler to a brick oven by a gravity method.

Expert opinion on a homemade heat exchanger in a heating furnace

Professionals make a few comments about installing a boiler in a heating system:

- Effectiveness of the result of the combined system without overpayments.

- The ability to use any type of fuel. Sawdust, coal, pallets, and wood stored in a dry place will do.

- The furnace unit, which has a water boiler, does not need to be heated constantly. Fuel is put in once every 12-24 hours.

- The system, where the long-term type of combustion is implemented, allows the building to be heated qualitatively and provided with hot water supply.

- In the absence of welding skills and understanding of the manufacturing process, homemade heating devices should be avoided. As an exception, installation is considered in the country or in settlements with power outages.

- The optimal type of chimney for a stove with a boiler tank is bell-type. A heat exchanger in the form of a register made of pipes with a large cross-section is placed inside.

- In order not to spend money on copper fittings, you can work with seamless pipes. They do not crack when heated.

A home-made solid fuel unit with a water-type circuit is allowed to be used in winter. It will quickly and efficiently heat a large house, ensure the uninterrupted supply of hot water. Before starting work, you need to choose a high-quality material for the heat exchanger, which will not heat up from the surface of the furnace structure.

A heat exchanger in a furnace is a good idea, but implementing it as presented here is a waste of money if this heat exchanger is in direct contact with the fire.Over time, the metal burns out, though I don't know which metal will burn out faster - copper or iron))). I have a stove at home and the upper brickwork is at corner 50, the thickness is decent - about 5 mm. It lasts for a maximum of 5 years, and then it bends under the influence of fire. And surely many have come across the fact that if a pipe is made of metal, which is especially practiced in baths, then it burns out quickly enough. To avoid problems, it is necessary to isolate the heat exchanger from the fire - it is better to place it in a brick “jacket” and then it will serve for decades. And so you can lose the stove and the heat in the house at one moment.

My grandfather had two cast-iron batteries, five sections each, installed in the furnace as a heat exchanger. All boiler houses are based on cast iron heat exchangers

well done, a lot of work, but the boiler is taken into account for uniform combustion and heating in all directions, however, the gases go out into the chimney and the heat exchanger must have a large heating area in this direction, i.e. in a staggered manner pipes are welded in 2-3 rows towards the chimney and also, a straight line is welded into the upper plane of the tank, preferably.

The expansion tank of an open type cuts into the return line to the pump; during your tie-in, there will be water shocks (knocking).

Do you have a kettle on a gas stove how long does it last for 5 years? That's right, if you put it on a fire without water, it will burn out and in half an hour And there is water in the pipes so that for 20-25 years it will be enough, and if pipes with a diameter of at least 50 ate less, they will boil faster then you need to put a pump more powerful And the stove operator who blocked the firebox with a corner spit in your face is not the stoveman, but the shabashnik who ripped the money off you And if you put the heat exchanger in a brick jacket it will be problematic to heat it, imagine how much firewood will be needed

Your square burns out because there is nowhere to give the received heat.