To organize a heat supply system for a private house or apartment, the most acceptable option is a closed heating circuit. It is characterized by a high degree of reliability, efficiency and the ability to adjust the main parameters. However, to create a professional circuit, you need to know what a closed heating system consists of: expansion tanks, circuits and the required equipment.

Features of designing a closed heating system

The principle of operation of closed-type heat supply is to create an increased pressure. This is due to the thermal expansion of hot water or other heating medium. At the same time, the pressure in the closed heating system of a private house promotes better circulation and, as a result, an even heat distribution.

Unlike gravitational schemes, before installation, it is necessary to learn in detail how a closed heating system works. When the coolant heats up, it expands and increases pressure, which provoke the beginning of circulation.

But that may not be enough. And so a pump is added to the system. It allows you to increase the speed of movement of hot water and thereby reduce the degree of cooling of the coolant in the return pipe. This leads to a decrease in energy consumption.

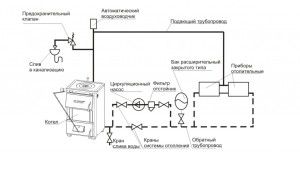

For design, you need to know the closed-type water heating device, its minimum configuration. It should consist of the following components:

- Heating element... It can be a boiler of various types - gas, electric, solid fuel. The main condition is safety of work and a proper indicator of power. A heat exchanger must be installed in its design for connection to a closed-type heating system;

- Pipelines... They provide hot water delivery to radiators and radiators. The defining requirement is the ability to withstand the maximum and operating pressure in the closed-type heating system and the temperature effect;

- Radiators and batteries... With their help, heat is transferred from hot water to the air in the room;

- Expansion tank... A key element in the circuit, since it is designed to stabilize the operation of the heat supply. If the critical pressure value is exceeded, the expansion tank for closed-type heating compensates for it, thereby avoiding the occurrence of emergency situations;

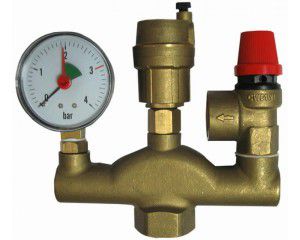

- Security group. Performs the same functions as the expansion tank, but in a more complete volume. Correct installation of the safety group in a closed heating system consists in the installation of an air vent and a drain valve. It is important to determine the location of these elements in advance.

To ensure control of the operation and the possibility of regulating the parameters of heat supply, it is necessary to install temperature and pressure sensors. Additionally, the heating circuit with a closed expansion tank must provide for the installation of a pressure sensor on the air chamber of the device.

For large areas, a two-pipe closed heating system is recommended. Despite the relatively large initial costs in the future, it will be able to ensure the efficient operation of heat supply.

Closed heating circuits

The primary task in the design of closed-type heat supply is the choice of the optimal scheme. First of all, this concerns the routing of the piping and the installation of the required components.

It is also necessary that the filling of the heating medium into the closed heating system work in automatic mode to ensure safety and stability.

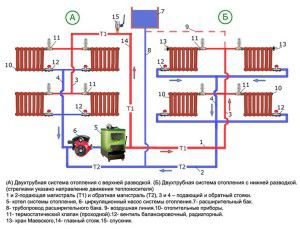

For heat supply of small areas, a closed one-pipe heating system is most often installed. Its scheme includes one pipeline to which radiators are connected in series.

At the same time, space for the installation of devices is significantly saved, and the primary costs for the purchase of components are reduced.

However, a significant disadvantage of a closed one-pipe heating system is the small heating area. The maximum length of the line can be only 30 m. If this parameter is increased, the temperature imbalance of the system will be observed.

To increase efficiency and reliability, a two-pipe closed heating system is installed. In addition to the main line, a return pipe is provided in it. In this case, the radiators are connected in parallel. Those. the main flow of hot water flows through the supply line and enters the heating devices through connections with tees.

The decisive advantage of this closed-type heating system scheme is the increase in the area of heat supply.

At the same time, the indicators of heat distribution in the rooms in the house do not deteriorate. But for greater efficiency of the heat supply, it is recommended to install thermostats on the batteries, and also connect a programmer to the boiler.

The advantages of a two-pipe closed-type water heating device are as follows:

- High maintainability rate... In case of failure of one of the elements, it is enough to block the access of the coolant in this area. Thanks to this, the installation of a safety group in a closed heating system can be carried out even with an active heating supply;

- Temperature regulation in each room... This requires the installation of thermostats in the piping of heating radiators;

- Automatic water replenishment option... To do this, you need a block for filling the coolant into a closed heating system, which is installed on the return pipe. In a closed one-pipe heating system, this can lead to thermal shock.

It is necessary to first calculate all the heating parameters. To do this, it is best to use specialized programs. Otherwise, the question may arise - where does the air come from in a closed heating system. This is often a phenomenon that is associated with the oxygen content in the coolant, its composition and the temperature regime of the system operation. To minimize it, it is necessary to install a safety group in a closed heating system.

For compactness of heating, it is recommended to choose schemes of a two-pipe closed heat supply system with horizontal pipe routing. But in this case, the installation of a circulation pump is mandatory.

Expansion vessel in a closed heating system

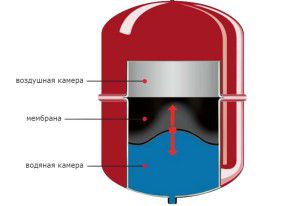

To control the operation of the heating system, devices are needed to ensure its safety. One of them is the expansion tank. It compensates for the excess pressure resulting from overheating of the coolant. But before installing it, it is necessary to calculate the expansion tank for a closed heating system.

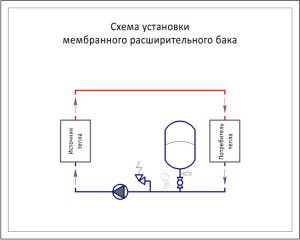

The normal pressure indicator in a closed heating system of a private house should not exceed 4-5 atm. Otherwise, the likelihood of depressurization of pipes and batteries increases. To stabilize the working pressure in the closed heating system, an expansion tank is mandatory.Structurally, it consists of two chambers - air and water. The first is designed to compensate for the expansion of the coolant, and the second is connected to heating. In heating circuits with a closed expansion tank, it is provided for its installation on the return line in front of the circulation pump. This is due to the fact that the elastic membrane should not be affected by constant hydraulic vibrations resulting from the operation of the pump.

One of the advantages of operating a closed heating system is the lack of direct contact with air. But to compensate for the expansion of the water, a reserve space is needed. It is for this task that the installation of an expansion tank for closed-type heating is done. Before that, you should correctly calculate its characteristics.

To calculate the expansion tank for a closed heating system, you need to know the following system parameters:

- Coefficient of thermal expansion of the heat carrier - E... For water, this value is 0.034 at a temperature of + 85 ° C;

- The total volume of water in the system - FROM;

- Initial pressure - Rnach;

- Maximum pressure - Rmax;

- Fill factor - Kzap.

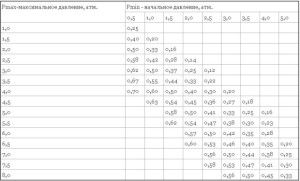

The last parameter can be found from the data in the table. Often, the question of why the pressure in a closed heating system drops is due to the wrong choice of the expansion tank.

Suppose that, according to preliminary calculations of a heat supply circuit with a closed-type expansion tank, the values of these parameters correspond to the data from the table.

Parameter | Value |

| Coefficient of thermal expansion of the coolant | 0,034 |

| Total water volume in the system | 360 |

| Initial pressure | 1,7 |

| Maximum pressure | 4 |

Based on this, we find the optimal fill factor. In our case, it will be equal to 0.5. Further calculation of the expansion tank for closed-type heat supply is carried out according to the formula:

V = ((E * C) / (1- (Rmin / Rmax))) Kzap

After calculations, we find the optimal volume of the expansion tank. To stabilize the pressure in a closed heating system of a private house, a model with a volume of 40 liters is required.

Most expansion vessels have a non-separable body. But for large structures, they provide for the possibility of replacing the elastic membrane. These models have a special flange.

Overview of safety groups for closed heating

The selection of safety elements is a key point in the design of a closed-type heat supply system. They must ensure the uninterrupted functioning of the heating, as well as prevent the occurrence of dangerous situations.

Knowing the principle of operation as a closed heating system, it can be determined that the greatest danger is the excess of the working pressure. At high rates of this parameter, the operation of the expansion tank will not be enough. Therefore, the only way out is to remove the excess coolant from the system.

This function is performed by the drain valve. When the critical pressure indicator is reached, the stem opens in it, and part of the coolant is drained into the sewer. If the device is incorrectly configured, its operation can cause a drop in pressure in a closed heating system.

The next element of heat supply is an air vent. It would seem, where can the air come from in a closed heating system? If the heating level of the coolant exceeds the critical one, water can go from liquid to gaseous state. At the same time, air locks are formed, which negatively affect the performance of the system. For their timely removal from a two-pipe closed heat supply system, an air vent must be installed.

To stabilize the working pressure in a closed-type heat supply system, it is necessary to install elements of safety groups in the following parts of the diagram:

- Air vent... Installed in the standard set of the safety group immediately after the boiler, in the highest part of the system and on all risers;

- Drain valve... Also part of the security groups. Additionally, it is mounted in distribution manifolds and system branches.

Correct installation of the safety group in a closed heating system is carried out at the final stage of installation. Only then can the system be tested.

The characteristics of the safety group must correspond to the design indicators of the heating. It is also necessary to check the functionality of the components of the group before each heating season.

Problems during the operation of closed-type heating

Knowledge of a closed-type water heat supply device and the correct choice of its components will avoid many problems during the operation of the system. But some of them will arise in any case. Let's consider the most common deviations in heating operation.

The most common cause of emergencies is the excess of the design characteristics of the system. There may be several reasons for this - an unidentified security group, a violation of the boiler operation mode.

Therefore, before each heating season, you should check the elements of the system, and also flush it. Otherwise, a blockage in pipes and radiators will lead to an artificial decrease in the volume of the coolant, reduce heat transfer.

Deviations in the operation of the heating system and possible remedies:

- There is air in a closed heating system... This may be due to the wrong composition of the coolant. When pouring the coolant into a closed heat supply system, it is recommended to use distilled water, since it does not contain alkalis and metals;

- Constant pressure drop in the system... This may be due to the presence of microcracks in pipes or radiators. The gradual outflow of the coolant provokes a decrease in pressure, and can also cause the formation of air locks;

- Expansion tank does not work... The reason is the wear of the membrane as a result of strong pressure on it. This happens if the tank does not have an air relief valve. For a non-separable structure, the only way out is to purchase a new one. In a tank with a mounting flange, you can replace the diaphragm yourself.

For quick elimination of emergencies, it is recommended to purchase repair kits. With their help, you can close the gap that appears in the pipe or radiator, and thereby stabilize the operation of the entire system. In the future, you can replace the damaged heating element.

The video shows an example of piping an expansion vessel for a closed heating system: