The use of underfloor heating systems for home heating is beneficial from an economic point of view. Despite the significant labor costs, the funds invested in it pay off within a few years. Efficiency and payback time depend on the correct preparation of all the layers included in the composition, which are called the "warm floor cake".

Assigning a Multi-Layer Structure

From a constructive point of view, a warm water floor cake is a set of elements laid in a specific order, including water pipes or an electric cable. The main purpose of this design is as follows:

- reduction of heat losses in the heating system;

- protection of heating elements from moisture and steam penetration into them;

- heat flow control;

- reliable sound insulation.

The elements of the puff set protect the heating system from mechanical damage.

Advantages and disadvantages

A cake with floor insulation in a wooden house guarantees the following benefits:

- ensuring a high level of heat transfer;

- high-quality thermal insulation of the floor;

- reliable and safe placement of work items;

- obtaining a high-quality coating with a uniform distribution of the thermal field;

- durability and maintainability.

The multilayer structure allows for good sound and heat insulation in the room. The disadvantages include the complexity of manufacturing and the need for careful preparation of the base for the water system.

Laying scheme

Before preparing a cake for warming floors in wooden houses, you will need to decide on the choice of the base, which is traditionally used as:

- ordinary soil;

- dry or concrete screed;

- wood floors.

Each of the formation schemes needs separate consideration.

Underfloor heating cake

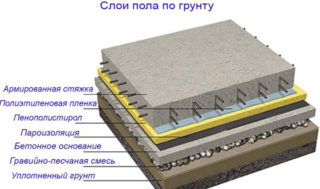

Before arranging a water floor under the ground, it is necessary to prepare a flat and solid foundation. For this, all excess is removed from the surface of the soil, including debris and plant roots, after which it is carefully compacted. Sand is filled in with a layer 10-15 cm thick, the substrate is watered by air-droplet method, and then a layer of crushed stone of the same thickness is poured onto it and compacted.

Upon completion of the preparatory procedures, they proceed directly to laying the cake. For this, the following operations are performed:

- A reinforcing metal mesh is laid on the prepared soil.

- It is poured with a previously prepared cement mortar 5-10 cm thick with permissible irregularities of 2-3 mm.

- Waterproofing is laid on the dried monolithic screed - it can be sheets of roofing material, plastic film or PVC.

- A layer of thermal insulation is covered - its function is performed by expanded polystyrene or extruded polystyrene foam.

- A rough screed is arranged on top, and then a reinforcing mesh is mounted, used as a reinforcement of the base.

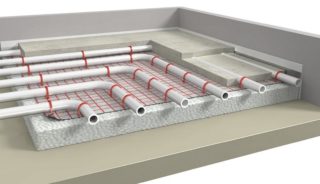

In the form of a snake or a spiral, the water circuits of the system are laid, after which they are completely poured with concrete. In conclusion, it remains to make a final floor covering.

For dry screed

A dry screed is understood as a base made of loose leveling materials, on top of which plywood or drywall is laid for reinforcement. In this case, the underfloor heating cake is formed according to the following scheme:

- A sealing damper tape is laid around the perimeter of the room.

- Sand or expanded clay in fine fractions is poured onto the rough concrete floor, which are carefully compacted.

- Pipes of the underfloor heating circuits are mounted on top.

- Dissipative thermal plates are installed directly on them.

At the final stage of work, one or two layers of drywall are laid on top of the structure.

Under the concrete screed

In the case of using a wet concrete screed, the sequence of operations for placing the components will be slightly different.

- A waterproofing layer is laid on the prepared base along the perimeter of the walls.

- Insulation is being laid, which is used as foam or extruded PPS.

- The insulation is covered with a heat-reflecting foil.

- A damper tape is glued along the walls of the room at the very joints.

- The contours of the heating system themselves are laid on the reflective layer.

- On top of them, a reinforcing mesh is mounted, along which beacons are installed to level the concrete screed.

- Pre-prepared cement mortar is poured over the exposed beacons.

Before proceeding with the installation of the final floor covering, it will be necessary to make an exposure of at least 30 days. During this time, the concrete screed will completely set and dry.

Under the wooden floor

A feature of this type of formation of a warm floor pie is the laying of its layers and pipes between wooden logs. The sequence of working operations in this case looks like this:

- On the subfloor, mats of heat-insulating material are laid, which is used as mineral (basalt) wool.

- A layer of foil is mounted on top, which is a good heat reflector.

- A frame made of logs is equipped, between which the pipes of the heating system are laid.

GVL plates are used as a supporting base mounted on top of the pipes. The specificity of the formation of a frame pie over a wooden floor is the possibility of laying a finishing coating immediately after the heating structure is ready. In this case, the thickness of the water-heated floor cake depends on the selected standard size of the log and the protective overlap.

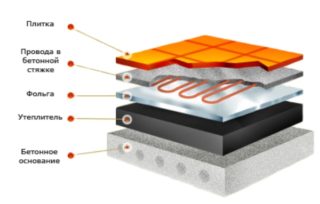

Installation under the electric floor

Unlike water systems, a cake for an electric floor heating is not so difficult to make. This is due to the lack of the need for thorough preparation of the base. In all other respects, the sequence of operations carried out is similar to the actions for the formation of a water floor system.

- A layer of insulation is laid on a concrete or wooden base.

- Polyethylene with heat-reflecting foil is placed on top.

- The heating elements themselves are placed on it and then fixed.

- A polyethylene waterproofing layer is laid on top.

In the end, a finishing coating is made of laminate or linoleum.

The need for insulation in a multi-layer structure of a warm floor

Insulation during the formation of a warm floor cake is necessary to eliminate heat loss towards the rough base. This contributes to the redistribution of heat flows in the direction of living spaces and allows you to optimize the temperature of the coolant - to save on energy resources. In this way, it is possible to insulate the floor by means of solid materials with a density of at least 35 kg / m3.

The insulation can be ordinary or extruded polystyrene foam, the characteristics of which allow it to be used as part of a puff cake. The minimum thickness of the insulation boards is on average 20-30 mm.Manufacturers recommend using 30mm foam when there is a heated room under the floor. If there are non-heated (non-residential) areas or a soil layer under it, you will need to lay a heat insulator up to 50-100 mm thick. In reality, an increase in this indicator entails an increase in the thickness of the entire pie, which is not always desirable, since in this case part of the living space is reduced.