During construction and finishing work, different fasteners are used: nails, staples, screws. With their help, boards and insulation materials are fixed. The main type of insulation retainers are dowels, but can also be used with glue or laying between rafters. Various materials and fasteners are used to insulate surfaces of different purposes (piping, facades, walls, foundations). Before starting work, you need to figure out which type is suitable for specific conditions.

The main methods of fastening insulation

The method of fixing the insulation depends on its structure and the surface on which the material is installed. Soft heat insulators are conveniently fastened with a lathing. On concrete and brick walls, the insulation is fixed with dowels and glue.

Fixation with lathing

This method is used for laying soft insulation (mineral wool). A frame is created from bars that are located at a distance equal to or slightly less than the width of the thermal insulation. As a result, cells are obtained in which the slabs are stacked.

The most common area of application is for insulation of interior walls, floors, roofs and ceilings. It is used outdoors when it is necessary to make a ventilated facade. The frame in this case is made of a metal profile. If the cladding will be in the form of a wet facade, this method is not suitable. A soft heat insulator will not support the weight of the facing plaster layer.

Fixing on dowels and nails

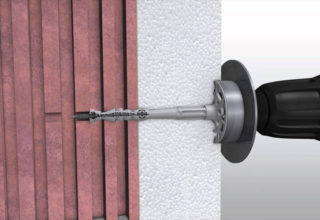

The insulation is fixed on a hard surface with dowels and nails. There are three types of dowels - plastic, with a metal nail and with a metal nail with a thermal head.

When choosing thermal insulation clips, it is important to choose their size. In the case of fixing thermal insulation to a brick wall, the length of the holder should be 70 mm longer than the thickness of the insulation board. Plastic products are used if the maximum length does not exceed 120 mm.

Fixing with glue

This method is optional. There are many adhesive substrates for installing insulation. They have minimal differences, but it is important to ensure that the glue is suitable for the specific type of heat insulator and surface. When working, it is important to look at the composition. It doesn't have to be coarse. If the glue has such a consistency, one can judge about improper storage and unsuitability for work. Suitable for installing styrofoam on walls.

Poppet mount

The dowels that are used to install the insulation have a specific shape. They are also called fungi or umbrellas. The clamps allow you to securely fix even the most fragile material. With their help, you can attach thermal insulation to concrete, stone, brick.

Positive aspects of poppet mounting:

- Reliable adhesion to the surface, which is ensured by the wide head of the fungus.

- Exposure to significant loads.

- To improve adhesion, a rough part is made on the surface of the cap.

- Anti-corrosion resistance.

- They are made of inexpensive plastic with good characteristics.

- Does not damage the seal.The umbrella is a flexible element.

- Strengthening the structure of the retainer by expanding the dowel in all directions.

The mushroom dowel itself can be made of plastic or steel. The choice of this or that material depends on what kind of insulation will be laid on the surface. There are differences in configuration and workmanship.

Plastic fasteners

Plastic holders are the cheapest, while their quality does not deteriorate. The umbrella surface has conical holes for added grip. To mount non-solid materials, use high quality polypropylene nylon mounts.

Features of plastic fungi:

- Low cost due to simplicity and low cost of production.

- They do not react to temperature fluctuations.

- Low level of thermal conductivity.

- Ability to work in harsh conditions.

- Do not rot or rust.

- Able to withstand a load of 400 kg / m2.

Such products are actively used to install insulation on brick and concrete surfaces.

Metal fasteners

The nail for fastening is made of steel. Sleeve - made of polypropylene with spacers located at the end. This design makes it possible to increase the load. The main area of use is the arrangement of building facades. Among the disadvantages are:

- The high cost of products.

- Risk of rust formation on contact with water.

- Condensation appears.

Do not use metal products in rooms with high humidity.

Thermal head fasteners

The device is a metal rod with a polyamide-coated cap. Thanks to this tip, the problem of condensation is solved, as a result of which rust does not form on the plaster.

Scope of application - wooden houses. The main disadvantage is that models with a thermal head are the most expensive in this segment.

Warming with fungi fasteners

The technology of installing thermal insulation using a dowel-fungus does not cause any particular difficulties for the master. It is important to prepare the necessary tools in advance before attaching the insulation to the concrete wall.

For installation, you will need a bucket, a drill with a whisk, a spatula for applying the composition to the wall and a perforator with a drill of a suitable diameter for the dowel.

Fastening of mineral wool to the wall with fungi is not made, since such thermal insulation does not need additional fixation. Suitable for fixing foam, foam, polyurethane foam and other hard materials.

Step-by-step instructions for attaching insulation:

- Surface cleaning. The material will be securely attached only to a flat surface without cracks and protrusions.

- Vapor barrier. In addition to its main purpose, this layer will perform the function of additional fastening.

- The area of the insulation must be marked for drilling holes. The pitch is 0.8 m horizontally and 0.3 m vertically.

- Making holes for dowels. The diameter should be equal to the section of the fastener leg.

- Manual insertion of the sleeve into the hole. The core must be placed in a sleeve and hammered in until it stops. The umbrella should be opened with a special protective cover.

To prevent the insulation from slipping, place a guide bar along the bottom of the wall. In the case of additional fixation on the glue, the fungi are installed after the composition has completely dried.

It is important to be able to correctly select the number of retainers. This can be done using the formula:W = S * Qwhere W - number of dowels, S - coverage area, Q - the number of dowels per meter. For 1 meter penoplex you need 4 holders, for basalt wool this value is 6. It is recommended to buy a little more products to have a stock.

Examples of fastening different materials

Foam and mineral wool are some of the most famous and used heat insulators. Their field of application is wide - from surfaces inside the house to foundations and pipes. On their example, the fastening of the insulation to the wall will be considered.

For foam insulation, you should choose a material with a width of at least 100 mm. If this is not the case, you can take two layers of 50 mm each and lay it in two rows. For the work to go faster, the width of the insulation must correspond to the location of the rafters. Installation of polystyrene is carried out using polyurethane foam or glue. When tightly laid, foam can be glued to the walls of the rafters only at least at the joints. If plastering work is to be carried out, it will be necessary to use the double sheathing method. When laying in two layers, it is important to half the slabs of the new row relative to the previous one. This will reduce the number of joints through which heat can escape. Before installation, be sure to put waterproofing. As an additional retainer, a board or rail is used, on which a finishing finishing material is later placed on top.

Material in rolls or slabs is excellent for fixing insulation to the bottom of the ceiling. In this case, the installation of rolled mineral wool is not difficult. It can be easily cut into slabs of the desired size and placed between the logs. The cut piece should be about 4 cm larger than the distance between the beams. The resulting strips are placed in cells. Additional fastening of the insulation to the wall with fungi is not required. If desired, the mineral wool can be additionally fixed on small diameter nails and twine. Nails are driven into the logs at a distance of 0.5 m, a thread is pulled over them, which holds the thermal insulation. In this case, the insulation fasteners will be more reliable.