Thermal panels for exterior home decoration are popular for combining aesthetics with practice. The cladding material has thermal insulation properties, helps to present housing in a presentable form. Installation is not a hassle - self-installation is possible. Before finishing, it is recommended that you familiarize yourself with the existing types of facade thermal panels for exterior decoration of the house and their characteristics.

Types of thermal panels and their features

Warm facade panels, in contrast to aerated concrete material, allow you to save on heating your living quarters during severe frosts. The cost savings are due to the improved energy saving parameters.

The product consists of two parts:

- insulated layer;

- facing.

Polyurethane foam and expanded polystyrene act as insulation. The decorative component is presented in the form of clinker, ceramics, granite, artificial stone, etc.

There are also three- and four-layer models on the market. In addition to the standard elements, this includes moisture resistant OSB particle board and refractory layering.

Metallic

For production, aluminum or galvanized steel is used. The surface layer is made smooth, glossy or perforated. The mounting edge of the panels is also perforated.

Measuring characteristics:

- thickness - no more than half a centimeter;

- steel structures weigh 9 kg / m2, aluminum - 2 kg less.

The protective coating is made of polymer. Polyester, plastisol, and pural are often used.

Product advantages:

- operational period - more than thirty years;

- resistance to frost, moisture, chemicals and mechanical damage;

- easy installation;

- noise reduction - 0-20 dB.

The main disadvantage of the metal is thermal conductivity, the coefficient is 50 W / m * K. Therefore, additional elements are provided.

Polymer

Vinyl facades are a common type of building structure cladding. It is made from the following elements:

- PVC;

- modifiers;

- stabilizers;

- dyes.

The surface of the siding is embossed or smooth. In the first case, wood is imitated, so the material will come out more expensive.

The advantages, in addition to the service life, are added:

- run-up of operating temperatures: -50 - +50 degrees;

- fire safety - G1;

- lightness - up to 5 kg per square meter;

- thermal conductivity index -0.15 W / m * K.

Resistance to ultraviolet rays is noted. In the sun, polymer tiles do not lose their color. Cons: fragility at low temperatures, vibration in strong winds.

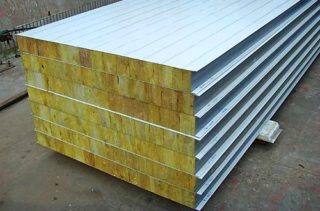

Sandwich panels

Sandwich panels are two metal sheets with a plastic plate pressed inside and a vapor barrier layer.

In addition to the standard advantages, sandwiches differ:

- bending strength;

- low thermal conductivity;

- protection against decay and corrosion;

- environmental safety.

The disadvantages include:

- the complexity of installation - careless handling reduces the strength of the panel;

- butt freezing - ice forms at the junction.

This option is one of the most expensive.

Fiber cement panels

The first difference is the multi-element composition:

- cellulose fibers;

- plastic;

- mineral filler.

Fiber cement boards do not withstand moisture, therefore, after contact with water, deformation of the insulation is observed. There is also a need to paint the panels after installation.

Glass Panels

Glass warm panels for facades belong to the VIP-class finishing, which is often used to decorate office buildings, stock exchanges, shopping centers. In the West, it is also used for furnishing a residential building in the style of minimalism or futurism.

Apart from the obvious design advantage, it is worth highlighting the practical aspects:

- heat and sound insulation;

- minimal influence of sunlight on the building.

Work with glass materials is many times greater than with standard ones. Difficulties arise in design, calculation and installation, so the price of such an installation increases.

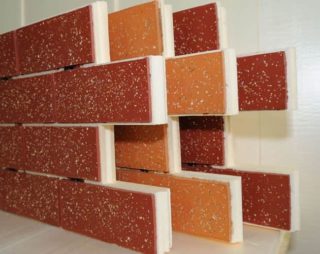

Clinker and composite

The standard clinker panel module includes:

- polyurethane foam insulation, thickness of which is 20-80 mm, EPS or EPS;

- polyurethane glue;

- clinker tiles.

In operation, they have a minimum load on the base and load-bearing walls. There is also a high level of resistance to moisture, ultraviolet radiation and mechanical stress.

The fragility of the decorative and insulation coating is noted. Therefore, careful handling and handling of clinker and composite materials is important.

Composite thermal panels consist of three layers: two aluminum sheets with a plastic layer in the middle. Equipped with PVDF protection for durability. Composite boards are fireproof, resistant to various atmospheric conditions and are available in different color combinations.

Composites by themselves do not have a good level of heat saving, however, the central plastic layer performs an insulating function.

Plastic siding

Plastic siding is a durable finishing material. There are two varieties on the market: "herringbone" or "ship board".

In addition to durable technical characteristics, in favor of vinyl siding are:

- ecological cleanliness;

- no need for additional maintenance;

- ventilation function.

Despite the lightness of the material, the installation is quite complicated. Sudden temperature jumps also have a negative impact on the strength of the structure.

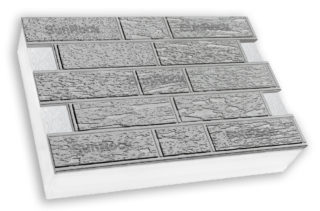

Imitation

Facade decoration with thermal panels imitating tiles, brick or stone is gaining popularity. The fundamental advantage is visual appeal. These varieties are used for certain design solutions. Also, buyers note the budget of the described option in comparison with the "originals".

Insulating the house from the outside with thermal panels is a good option. Before buying, you should evaluate the assortment, paying attention to thermal conductivity, plate sizes and other parameters depending on operating conditions.

Characteristics influencing the choice of thermal panels

When choosing, consider the following:

- Eco cleanliness and price. If you do not want to harm nature, you need to choose mineral warm panels for the facade. If there is no difference, PSB, PPU, EPPS, PVC are suitable.

- Appearance. Modern design trends recommend opting for glass products. Builders advise choosing sandwich panels, clinkers and composites.

Technical characteristics are taken into account. The lower the heat transfer coefficient, the more money is saved on heating. The high level of sound insulation will ensure that there is no external noise.

Advantages of finishing material

Warm facade panels have the following advantages:

- practically zero thermal conductivity;

- strength, density and rigidity, working for the insulation of the facade;

- simplicity and speed of installation;

- small dimensions;

- vapor permeability - no condensation and high humidity.

The high price is compensated by the quick installation and long service life. Self-assembly is possible, which will help to save costs on payment for the work of installers.

Installation technology

To insulate the outer surface of the house with thermal panels, it is necessary to prepare the walls. There are two ways to install:

- frame;

- frameless.

The second option is suitable when the walls are flat. In this case, it is recommended to remove the exfoliation of obsolete plaster, to minimize irregularities with plywood or polyurethane foam.

When there are significant differences on the wall surface, a leveling crate (frame) is installed. This move creates additional ventilation space between the wall and the home.

Installation takes place in several steps:

- The cladding is carried out from the lower left corner upwards.

- A guide made of aluminum is installed horizontally along the perimeter of the building.

- The lathing made of treated wooden bars or metal profiles is fixed to the wall. Here they use screws or dowels.

If there is a plinth, the plinth profile is pre-calculated as a support for future panels.

In the installation process you will need:

- hammer drill or drill;

- polished machine;

- screwdriver;

- level;

- putty knife;

- screws, dowels, grout;

- construction foam;

- washers;

- slopes and basement profile.

First, the lower horizontal level is struck, which is located approximately 150 mm below the floor. This stops the cold air flow through the upper plinth. The base profile is fixed along the resulting axis.

The first panel is installed in the lower left corner. Outlines are made for holes in the wall. After that, the lining is fixed with self-tapping screws.

The next panel is mounted on the right side, the fragments are inserted into the grooves of the first panel. This continues to the very top of the building structure. Elements with offset rows are placed in the corners of the finished structure, forming grooves.

It is recommended to additionally use polyurethane foam for fixing.

Finishing touches: grouting with a frost-resistant substance, cleaning the resulting surface from dust and dirt. The seams are processed with an airtight mixture, which ensures reliable fastening of the joints and prevents moisture from penetrating under the thermal panel.