Bimetallic radiators are made not from one, but from two dissimilar metals. These products first appeared on European markets over 50 years ago. They quickly gained recognition from the general public, due to their high quality indicators and reliability of operation in existing heating systems.

The device of bimetallic radiators

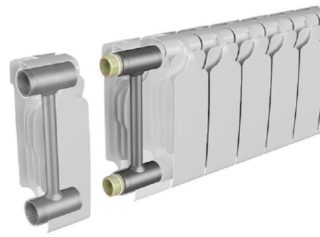

The main difference between bimetallic batteries and homogeneous analogs is that inside them there is a stainless steel case, on top of which there are aluminum fins. This design makes it possible to exclude direct contact of reactive aluminum with a liquid medium. The steel base is more resistant to destructive effects, due to which the service life of heating batteries is increased. According to manufacturers, this figure reaches 20 years for some models.

The steel body provides increased structural strength. The working pressure of bimetallic heating radiators can reach 40 atmospheres. Thanks to this, such products can easily withstand water hammers, which often occur in heating systems. The peculiarities of the internal device with a complex relief of the channels for the coolant make it possible to obtain an optimal combination of its daily flow rate and thermal inertness. The features are complemented by the original design of bimetallic devices.

The advantages of bimetal

The advantages of bimetallic radiators include:

- long service life;

- good strength indicators;

- increased heat transfer and efficient heating of large premises;

- resistance to corrosive destruction;

- short reaction time to the thermostat actuation;

- attractive appearance.

The aluminum framing of the radiators fits perfectly into the interiors of modern premises, the division into collapsible sections allows you to choose the desired dimensions and power indicator.

Radiator manufacturing options

Bimetallic structures are produced in the following two versions:

- pseudo-bimetallic products;

- pure bimetal.

In the first of these options, the steel core is present only in some areas within the vertical channels. In these devices, aluminum is not completely protected from the effects of an aggressive environment, but only in the weakest places. Such models are somewhat cheaper, the average service life is about 10 years.

Purely bimetallic products have a one-piece steel body, which is poured on top with an aluminum alloy under high pressure. Such models have a much higher degree of protection, they are more expensive, their service life, other things being equal, reaches 30 years. In accordance with the features of installation, radiators of this class are divided into collapsible and non-collapsible.

The first ones are disassembled using a conventional radiator key. With its help, it is possible to add one or more sections to them, or vice versa - to dismantle them. They are installed in private houses with autonomous heating systems, where the developed pressure is low.Non-dismountable radiators are made in the form of a monolith, which cannot be built up or attached to another product. These samples are used in city apartments, which are characterized by increased pressure in the heating network.

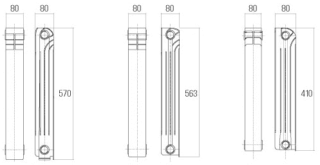

Dimensions of bimetallic batteries

When assessing the size of bimetallic radiators, one should take into account the place of their installation and permanent operation. When placed in niches under windows in a house or apartment, the selected battery must guarantee reliable protection from cold air entering through poor-quality seals. Commercially available bimetallic heaters are standard sizes.

The distance between the vertical bars of the heater is 200, 350 or 500 mm, depending on the specific model. These figures correspond to the center distance between the inlet and outlet radiator pipes. To determine the exact value of the specified parameter, add 40 mm on each side. In this case, with a center-to-center distance of 500 mm, for example, the overall dimensions will be 580 mm. The width of the entire radiator product depends on the total number of installed sections.

Selection recommendations

When choosing bipolar radiators, the main attention is paid to the declared technical characteristics and design features, when familiarizing with which the following points are taken into account:

- Monolithic products withstand pressures up to 100 atmospheres and are suitable for homes where water hammer is often observed. Due to the high cost of monolithic structures, in all other cases, it is recommended to choose sectional models.

- The number of sections is selected based on the required heating level of the room.

- With equal capabilities of different models, they differ in the distance between the collector axes. This indicator can have both standard values (50 and 35 centimeters) and atypical ones.

Radiators with a small height of 20 cm are not produced by all manufacturers. Large values of this indicator (about 80 cm) are found only in models produced by the Italian company Sira.

Verified manufacturers of bimetallic radiators

The manufacturer's declared characteristics of bimetallic radiators determine the user demand for these models. Products on an all-steel frame are produced by the following companies:

- Italian manufacturer Global Style;

- Royal Thermo BiLiner from Italy;

- Russian Santechprom BM.

The list includes the Russian company Rifar. The MonoliB model produced by it has only a partially metal frame, due to which the thermal efficiency is increased. In addition, its cost is about 20 percent lower than that of products with an all-steel frame.

Three of the most popular manufacturers of bimetallic models:

- Russian company Rifar;

- Italian Sira;

- Chinese Gordi.

Verified manufacturers do not cause even the slightest doubt in the buyer.