Gas boilers are expensive equipment that needs constant care and protection from power surges in the network. Due to the poor quality of the power supply, special measures have to be taken to stabilize it. This explains the increased demand for modern models of gas boiler stabilizers, which guarantee a normal and stable power supply.

Recommendations for choosing a stabilizer for a gas boiler

To choose the right voltage stabilizer for a gas boiler, you need to decide on the following parameters:

- power consumption from the network;

- quick response to instant changes in input;

- input voltage range;

- the accuracy of the maintained voltage at the output of the device.

You should also choose a manufacturer that has a good reputation in the constant sales market. This applies not only to foreign, but also to domestic companies. It is necessary to decide on what voltage the boiler will be powered from (three-phase or single-phase). If the unit is chosen for heating small rooms and is designed for a power of up to 12 kW, a single-phase modification is sufficient. For a mansion with a large heated area, a three-phase boiler with a capacity of up to 14 kW and above may be required. For him, choose a stabilizer for 380 volts.

The speed of reaction to power supply deviations from the norm will save the equipment from its sharp fluctuations and surges (during a thunderstorm, for example). The characteristic that defines the range of input potentials will allow you to cover a wide range of possible deviations.

The accuracy of maintaining the output voltage is a parameter that determines the effectiveness of stabilizers for heating boilers and the reliability of protection of the latter.

Criterias of choice

You can determine which stabilizer is suitable for a gas boiler according to the following rules:

- for a conventional network, a single-phase unit is purchased;

- the power is selected 30-40 percent more than what the boiler itself consumes from the network;

- when this indicator is unknown, any stabilizer from 400 watts will do (except for the electromechanical version).

It is allowed to install "noisy" electromechanics (servo drive), but on condition that the stabilizing device is placed in the next room.

Types of stabilizers

Servo products

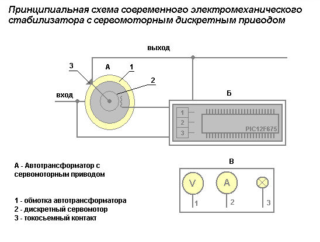

The main working unit of the stabilizers of this group is an autotransformer with a movable current-collecting contact. The adjusting element is designed as a slider or a removable brush of a special design. When adjusted, it moves along the transformer winding, increasing or decreasing the part of the energy transmitted to the output.

In older models, control was done manually. In modern models, the process is automated through the use of a special electrical module. An electronically controlled built-in motor automatically changes the position of the slider to equalize the output voltage. These devices are used in cases where high performance is not required.

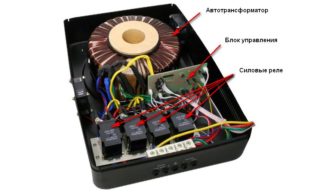

Relay

Relay stabilizers are devices that operate on the principle of step conversion. The circuit is based on an autotransformer, the output windings of which are switched so as to compensate for input deviations. The change in the number of turns in the secondary winding occurs automatically due to the operation of electromagnetic relays. A special block controls their switching. With its help, the parameters of the mains voltage are monitored, and, if necessary, the required stabilization stage is switched on.

The advantage of relay devices is a high response speed compared to drive models - 10-20 ms. The control modules in them are simple in design, which facilitates maintenance and repair of the finished product.

The disadvantages of relay machines include:

- intermittent regulation;

- insufficient working resource;

- increased noise.

The main area of application of these samples is low-power equipment connected to power grids with unstable input power.

Triac models (inverters)

The advantages of semiconductor inverters include:

- compactness;

- high performance;

- extended limits of adjustment;

- temperature stability;

- high efficiency;

- reliability.

The only drawback is the high cost of inverter devices.

Brand samples

Rating models of voltage stabilizers for the boiler are represented by relay and inverter units. Electromechanical analogs are almost never used. The first type is "Resanta ACH-500/1-Ts" with a declared power of 500 watts. The input voltage can vary in the range of 160-240 Volts, and the response time is 7 ms. The number of voltage regulation steps is 4, and one outlet (European standard) is provided at the output.

The manufacturer declared built-in protection against short-circuit and overheating, as well as against overvoltage and impulse noise. It is allowed to connect the device to the mains only with a grounding conductor. This sample is not very reliable. The wall-mounted version of "Resanta" additionally contains the letter "H" in its name and does not differ from ordinary models in anything other than the body.

The inverter-type units presented on the market are samples of "Shtil IS550" with double voltage conversion and power up to 400 W. The acceptable range of input variation is 90-310 Volts, and the response time is zero. Within 5 seconds, the device is capable of working with double overload.

"Calm IS550" belongs to the best models of inverter stabilizers, characterized by increased control accuracy (error - less than 1%). The device is absolutely silent and is cooled according to the convective scheme. This means that it dispenses with built-in fans.

Brief description of the principle of operation

In relay systems, relays are responsible for adjusting the output parameter, switching the turns of the transformer with their contacts. They change the amount of voltage taken from the secondary winding.When additional turns are connected, the output potential increases, and when they are disconnected, on the contrary, it decreases. Such a control circuit has a higher performance, but due to the presence of contacts, it is not very reliable - it has a small resource.

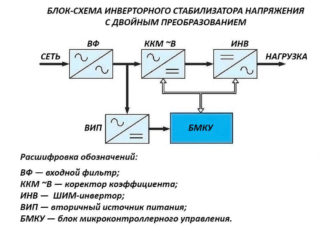

The most effective and reliable devices are inverter units built according to the double conversion scheme. The input voltage in them is first made constant, and then high-frequency pulses are formed from a stable potential. At the next stage, they are switched by powerful diodes, forming a voltage similar in shape to the input, but independent of the network. An electronic device works like this:

- When the electrical parameters are changed at the input, the built-in microprocessor sends a pulse to correct the shape of the monitored signal.

- Depending on the direction in which it changes, the control unit generates the required signal.

- After that, the shape of the output voltage is automatically corrected.

Due to the electronic control circuit, inverter models are characterized by high speed and quiet operation.