When designing a heating system, it is important to choose the right basic elements - a boiler, radiators and accessories. The configuration offered by the manufacturers is not always suitable for the operational parameters. And given the high cost, the question arises - how to cook heating with your own hands: boilers, registers, combs? This can only be done with the appropriate apparatus and minimal skills in working with it.

Choosing a welding machine and electrodes

Currently, manufacturers offer several models of welding machines with which you can make high-quality joints of metal of various brands. But before you properly weld the heating, you need to choose the optimal model. Let's consider the most popular types of devices and their main characteristics.

Transformer

The principle of operation is based on increasing the frequency of the incoming current. For this, step-up transformers are used. Despite its relatively large dimensions, this type of welding machine is best adapted to power surges. With its help, you can properly weld a heating boiler, observing the manufacturing technology.

Inverter

The formation of current according to the set parameters occurs due to the work of electronic circuits. They are characterized by a stable arc, which ultimately gives a high-quality seam. This must be taken into account before you properly learn how to weld heating yourself. However, they are extremely sensitive to voltage surges in the network.

It is recommended to purchase a voltage stabilizer as an additional equipment for inverter devices.

Is it possible to weld a boiler with your own hands for water heating using an inverter apparatus? Yes, but its characteristics must correspond to the parameters of the metal used. For the manufacture of heating elements, carbon steels are most often used.

Heating Welding Material Table

| Product | steel grade | Electrode type |

| Boiler body | St3, St3G and St4 | ANO3, MR-3, UONI 13/45 |

| Heat exchanger and boiler furnace | MSt2 and MSt3 | MTG-01K and MTG-02 |

| Pipes up to 100 mm in diameter | 12MX and 15XM | TsU-2XM |

| Pipes with a diameter greater than 100 mm | 12Х2МФБ |

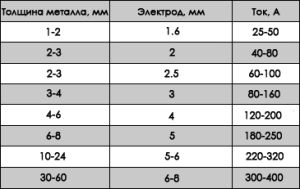

You also need to know the dependence of the diameters of the electrodes on the thickness of the welded metal.

As for the choice of a welding machine, experts recommend staying on inverter models operating on alternating current. Their cost is slightly higher than that of transformer ones, but they are smaller and with their help you can make a high-quality weld. This is important to consider, since the self-welding of the heating boiler must be of high quality.

The cost of an apparatus with a capacity of 7 kW, a welding current of up to 200 A and a maximum electrode diameter of 3.6 mm will be about 16 thousand rubles.

How to cook a heating boiler with your own hands

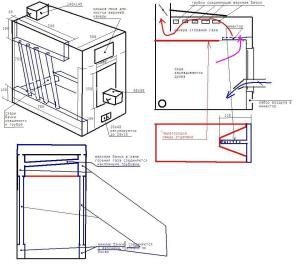

Before you weld a heating boiler yourself, you need to decide on its design. It is preferable that it meets modern safety and efficiency requirements. Therefore, as an example, a pyrolysis-type boiler made by ourselves will be considered.

How to properly weld a heating boiler of this type? In addition to the welding machine, this will require the following materials and tools:

- Sheet steel, grades of which are selected from the data in the table shown above. For a combustion chamber, the thickness of the metal should be 3-4 mm. The body can be made of steel with a smaller thickness - 2-2.5 mm;

- Pipes for the manufacture of a heat exchanger. Their optimum diameter is 40 mm. This size will allow you to quickly heat the coolant. The number of registers is from 3 to 6;

- How to weld a heating boiler without a cutting tool? It is best to use a "grinder" with special discs for metal for cutting sheets;

- Doors for the combustion chamber and blower. You also need to purchase cast iron grates. This must be done in advance, since the openings and fixing parts of the boiler will be made according to the size of the components;

- Level, tape measure and pencil (marker) for marking;

- Protective equipment - gloves, a welder's mask, transparent work goggles and long-sleeved heavy-duty clothing.

For clarity, you can see how to cook heating in a private house. Video or photographic materials will help in the work, since they clearly show all the stages and features of their implementation. However, this should be done only after drawing up a drawing and preparing all tools and accessories. This applies to all stages of the manufacture of components, since it is impossible to weld heating with your own hands, including boilers, registers, combs, without the correct scheme.

It is also important to prepare the place of work before welding the heating in the garage. Most often, the manufacturing process takes place in it. First you need to ensure maximum free space by removing unnecessary items.

For safety reasons, flammable liquids - gasoline, oil, etc. should also be removed from the garage. And only after that you can start working - weld the heating in the garage. Correct welding of a heating boiler consists in the manufacture of two components - directly the boiler body and the heat exchanger.

Heat exchanger

This element is made before the heating boiler is welded. Subsequently, it will be installed in a structure that will directly depend on its actual dimensions.

Structurally, it consists of 2 rectangular tanks, interconnected by pipelines. The optimum material thickness should be 3-3.5 mm. This is due to the high temperatures that will affect the surface. The specifics of its manufacture can be seen in the video - how to cook heating in a private house.

Housing

On sheets of steel, the structure is marked according to the drawings. First, the back panel is cut out and a partition is welded to it for the discharge of wood (coal) gases. At this stage, you need to be very careful, as the weld seam may not always provide proper fastening. Then the side and bottom are welded to the partition and the back wall.

It should be noted that it is quite problematic to weld a heating boiler yourself. Therefore, this work is recommended to be done together. This is especially true for the installation phase of the finished heat exchanger. Its pipes are placed in pre-prepared holes, and the pipes are point-welded to the inner walls of the boiler.

The question often arises - how to weld heating inside the garage without forced ventilation. For this, work must only be carried out with the door open to ensure a normal supply of fresh air.

The main problem with homemade designs is low efficiency. To increase the efficiency, it is recommended to make double walls, between which a basalt refractory heat insulator is installed. It is possible to cook such a boiler with your own hands for water heating, but for this you need to provide for additional material consumption.First, double walls are made, which are filled with insulation. Then the further technology of welding the structure is fully consistent with the above.

How to cook a heating register with your own hands

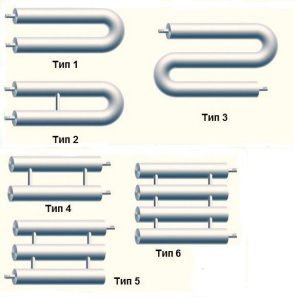

How to properly weld the heating register and in what cases is it recommended to install them? First you need to correctly understand their purpose. In fact, these are heating devices that must ensure maximum heat transfer from the hot water of the heating system to the room.

Before welding the heating registers, it is necessary to prepare the main material for manufacturing:

- Main pipes. They should be relatively large in diameter - up to 100 mm. For forced systems with a high temperature regime, it is recommended to use just such. It is better that the cross-section of the pipe is round, since the profile structures will create a large hydraulic resistance, which is undesirable;

- In order to properly weld the heating register, you will need pipes of a smaller diameter, which will serve as pipes for the circulation of the coolant between the main horizontal ones. Their cross-section should be in the range of 24-30 mm.

At the first stage of work, you need to cut all pipes according to a previously prepared drawing. Then, before welding the heating registers, it is required to make caps on the ends of large pipes. They are divided into two types - blind and with inlet nozzles. With the help of the latter, the movement of the coolant along the register contour will be carried out.

The order of work is as follows.

- In order to properly weld the register of the heating system, you must first cut off all the pipes according to the drawing. For this, a "grinder" is used. At the end of the work, the end parts are cleaned;

- Manufacturing of plugs. For them, you need to use metal of the same thickness as that of the pipes. The diameter of the plugs should be greater than the pipe section by the metal thickness. This is necessary to weld on the mounting flange. After their manufacture, installation is performed by a welded method;

- Before welding the heating system registers using transition pipes, it is necessary to make holes in the pipes. This is best done with a welding machine, since it is impossible to cut a round hole with a grinder.

The final stage of work is the connection of large pipes into a single heating device - a register.

How to make a comb for heating with your own hands

If the installation of radiant heating is planned, then a collector must be made for it. Is it possible and how to weld a comb for heating so that it functions normally? Yes, but first you need to find out its purpose.

It is necessary to distribute the coolant to individual circuits of the system. Externally, this is a pipe in which the pipes are to be installed. They are connected to separate lines of the heating system.

Since welding a comb for heating is similar to the process of making a register, there is no need to focus on this stage. It is important to note the difference in the connecting elements located at the ends of the structure. These can be flanges (as in the photo), or transition couplings from a smaller diameter of heating pipes (32 or 40) to a larger combs (50 mm is the optimal size).

For the manufacture of elements of the heating system, before starting to weld the heating correctly, you need to carefully study the possible design options. It must be remembered that the larger the combustion chamber, the more powerful the installation will be. Therefore, you must first calculate its volume.

For example, you can watch a video of welding heating in a private house, namely, the manufacture of a pyrolysis boiler: