The choice of components for the heat supply system will affect the efficiency of its work. Particular attention should be paid to operational properties. They also directly depend on the material of manufacture. That is why it is important to know the basic parameters of steel radiators and heating pipes: their characteristics, dimensions and technical properties.

- Features of the operation of steel pipes and radiators in heating

- Steel Radiator Models

- Method for calculating the power of steel radiators for heating

- Installation rules for steel radiators

- Recommendations for the operation of steel heating batteries

- Advantages and Disadvantages of Steel Heating Pipes

- Reviews of steel heating pipes and radiators

Features of the operation of steel pipes and radiators in heating

Before making the installation of steel heating radiators, you should find out their qualities and factors affecting the operation. Water is often the heat carrier in the heat supply. It is she who determines the duration of the maintenance-free operation of the system components.

The use of steel as the main material for the manufacture of heating elements due to its affordable cost, relative ease of processing and good technical qualities. Steel heating panels and pipes have the same characteristics. However, during operation, negative points appear. They consist in a decrease in wall thickness, a decrease in thermal conductivity.

This is due to the fact that steel pipes for heating and batteries made of this material are characterized by the following qualities:

- The appearance of corrosion... The oxidation process is natural regardless of the volume of the steel radiator. To reduce its speed, the water must contain a minimum of oxygen;

- Rough surface. This affects the hydraulic resistance indicator;

- Light weight... Often the installation of steel radiators can be done without help. This is due to the small wall thickness - from 0.8 to 1.2 mm;

- Loss of appearance due to poor paint quality... It is recommended to choose the model of batteries, the surface of which has been treated with a powder method.

Also, difficulties can be caused by standard installation technologies. If steel plate heating radiators are installed without any special problems, then a welding machine is needed to fix the pipes. The connection of assemblies with threaded couplings is not effective.

Often, the service life of steel heating pipes directly depends on the quality of the weld. For its formation, it is necessary to choose the right electrodes and the operating mode of the welding machine.

Steel Radiator Models

Unlike pipes, the popularity of steel batteries does not decline. This is due to the large assortment of models, the ability to choose several types of structures. But at the same time, reviews of steel heating radiators indicate the dependence of the quality of the product on the parameters of the materials used and compliance with the assembly technology.

Regardless of the model chosen, its defining parameters are heat transfer, overall dimensions and connection methods. The installation of steel heating radiators and further operating rules will depend on these characteristics.

There are currently three types of steel batteries to choose from:

- Panel... They refer to the budget option for the arrangement of heat supply, although there are also expensive models.Steel flat heating radiators consist of small diameter pipes that are connected using plate heat exchangers with heating panels. Power is determined by their number and overall dimensions;

- Tubular... They can be found much less often than the ones described above. This is due to the complexity of manufacturing. Despite the fact that reviews about steel tubular-type heating batteries are almost always positive - their range is small;

- Sectional. Outwardly, they look like cast iron batteries. They can also consist of several sections, which are interconnected by threaded components. The difference lies in the characteristics of the material of manufacture. Steel has a higher thermal conductivity than cast iron. Therefore, the former are characterized by low heat losses during power transmission.

In addition, when choosing, the dimensions of steel heating radiators, their nominal and maximum pressure, as well as the temperature regime of the heat supply are taken into account.

For centralized heating systems, the use of flat steel radiators is not recommended. They quickly fail with pressure surges characteristic of this type of heat supply.

Method for calculating the power of steel radiators for heating

One of the main characteristics of heating components is their rated power. Correct calculation of steel heating radiators can be done in several ways. First, it is necessary to calculate the characteristics of the system where the batteries will be installed and calculate the rated power of the heat supply.

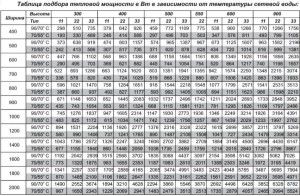

The maximum service life of steel pipes and radiators directly depends on the load and operating conditions. To increase it, you must perform the correct calculation before purchasing. To do this, you need to find out the heat loss in the room, determine its area and volume. Then, for the selection, a table for calculating steel heating radiators is used.

The simplest formula for calculating steel heating radiators takes into account the dependence of the volume of the room and heat losses:

P = V * 40 * R

Where R - the required nominal power of the radiator,V - the total volume of the room,40 watts - the rate of heat output per 1 m²,R - heat loss in the building.

To determine the last parameter, you need to know the properties of the material for the manufacture of external walls, windows and door structures. The determining factor is the coefficient of resistance to heat transfer. It can be learned from the standard building materials tables.

The method for sizing steel heating radiators is as follows:

- The rated power of the battery is determined.

- The optimal model is selected from the data in the table above.

- Once again, the compliance of the parameters of the steel plate radiator with the calculated data is checked.

Also, the amount of coolant that can fit into the batteries plays an important role. To calculate the volume of a steel heating radiator, you need to know its type and dimensions. But it is best to use the data from the technical passport. It usually indicates the rules for installing steel heating radiators, and their main operating parameters.

The selection of a heat supply device is carried out on the basis of the information provided by the manufacturer. You can determine the model using the table for calculating steel heating radiators, which is compiled for each model range separately.

Installation rules for steel radiators

The technology for installing components of heat supply systems directly depends on the chosen model. One of the advantages of steel flat heating radiators is their heavy weight. Those. the load on the wall where they will be mounted is reduced. It is important to choose the right installation location.To do this, during the installation of steel heating radiators, it is necessary to be guided by a certain procedure.

The installation location is determined first. This is usually the outer wall through which the greatest heat loss occurs. Unlike steel pipes for heating, radiators must have maximum heat transfer. If the installation is carried out under a window, the battery should overlap the structure by 2/3. This will improve the convection rate of the air currents.

During the installation of steel heating radiators, it is recommended to follow these rules:

- The intersection of the central axis of the battery must coincide with the same parameter of the window structure. Allowable deviation - 2.3 cm;

- The minimum distance from the floor plane to the steel heating panel varies from 6 to 10 cm;

- Controlling the location. This parameter is checked using the building level. All heat supply devices in one room must be at the same height;

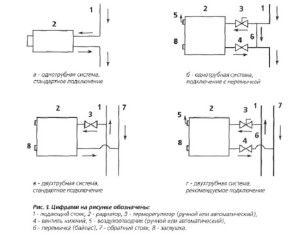

- The choice of connection method - side, top or bottom. Reviews of steel radiators indicate a good appearance of the device with a bottom connection. But this depends on the specific battery model;

- Compliance with the installation order. First, steel heat supply radiators are installed, and then they are connected to the system;

- Installation of additional components. These include shut-off valves, thermostats, Mayevsky taps.

At the end of the installation of steel heat supply radiators, pressure testing is performed, the integrity of the joints is checked. When filling the system with a coolant, it is necessary to open the Mayevsky cock to remove air.

All models of steel plate heat supply radiators have a non-separable design. They cannot reduce or increase the heating surface area. This is taken into account when choosing.

Recommendations for the operation of steel heating batteries

An important point is the observance of the operating rules. After the correct calculation of steel heat supply radiators, the appropriate model should be selected. At the same time, attention should be paid to the quality of the welded seams, the painting method and the thickness of the heating surface.

During the operation of the heating component, its characteristics will change. This is due to exposure to hot water, the occurrence of corrosion processes, and possible mechanical damage. To increase the service life of steel heating panels, first read the instructions for use. But there are general rules that must be followed:

- Checking the reliability of the connection to the heating mains. If necessary, replace gaskets or valves;

- Flushing. During operation, the volume of the steel radiator heat supply may change. This is due to limescale deposits that form on the inner walls of the pipes. Hydraulic or chemical flushing can be used for removal;

- Loss of appearance. This mainly applies to those models in which the surfaces were painted with a non-powder method. To restore it, you must use special heat-resistant paints. An alternative option is to install decorative panels;

- Periodic check of fastening of steel flat radiators heat supply. Reducing the reliability of mounting elements is the main reason for the appearance of extraneous noise during heating operation.

These are the main recommendations for the operation of steel heating elements. Additionally, it is necessary to take into account the modes of operation of the system.

Analyzing reviews of steel heat supply radiators, we can conclude that the main cause of failure is the excess of the rated pressure. To avoid this phenomenon, it is necessary to install a drain valve, an air vent and an expansion tank.

Advantages and Disadvantages of Steel Heating Pipes

Due to the appearance of polymeric materials for heat supply, the use of steel pipes in the standard scheme is becoming less and less relevant. However, in some cases, they are the only option. This is due to their unique properties.

The consumer is primarily interested in the service life of steel pipes for heat supply. It is determined by the parameters of the system, as well as the initial characteristics of the material of manufacture. The larger the pipe wall thickness - the longer the period of its maintenance-free operation. However, this increases the mass of the structure, which affects the laboriousness of installation. In addition to these properties, when analyzing the relevance of choosing steel pipes for heat supply, the following factors should be taken into account:

- Corrosion protection... This requires painting the outer surface of the pipe;

- Flushing the system... Performed according to the previously drawn up schedule. When choosing methods, the properties of the pipe material are taken into account;

- Good mechanical strength... They are often used for the manufacture of heating registers. However, this increases the volume of the coolant in the system;

- Particular attention is paid to the quality of the connection... Pipe joining is best done with a welding machine.

Installation of steel mains heat supply is relevant in industrial premises, commercial and public buildings. The reason for this is the high degree of mechanical strength. Installation in autonomous heating systems of houses and apartments is impractical. It is best to use polymer analogs instead.

Manufacturers in the nomenclature of steel pipes indicate their inner diameter. This must be taken into account when calculating the volume of the coolant in the heat supply.

Reviews of steel heating pipes and radiators

One of the ways to determine the relevance of the installation of a certain heating component is to read reviews of steel heat supply radiators. They reflect the actual performance of the device, indicate its advantages and disadvantages:

- For a long time, we had steel pipes for heating in our house. After replacing with polypropylene, we felt the difference. They do not need to be painted, heat losses have decreased. However, polymer pipes are inferior to steel pipes in reliability;

- At school, my son's old cast-iron batteries were replaced with steel radiators. But apparently they saved money where they didn't need it. In winter, leaks periodically appeared, after the first heating season, paint fell off on some of them;

- We purchased Kermi steel radiators to complete the heating system. The quality is beyond praise. The fasteners are reliable, even with pressure surges, there is no extraneous noise. Additionally installed thermostats.

When choosing steel radiators and pipes for heating, it is necessary to make a preliminary calculation of the parameters. To do this, you can use special programs, or perform calculations manually. It is best to use two methods for maximum calculation accuracy.

In the video, you can familiarize yourself with the main characteristics of steel radiators for heating:

You say that steel radiators should not be used in heating, but they are exactly what we have in a new building. How to be?

If at the moment there are no problems, then nothing should be changed, because the house will still settle down and settle down. But with a future overhaul, it is recommended to replace the radiators with newer and more reliable models.