Double-circuit heating is the most efficient and reliable way to heat a living space. It is used in houses with a different number of floors. Heating on two circuits from one boiler allows you to regulate the temperature in a separate room without changing the temperature regime in other rooms. The main feature: separation of the forward and reverse circuits of the heat carrier. According to the first, the heated water from the boiler is supplied to the heating system, according to the second, the cooled heat carrier is returned to the heating unit.

Main advantages

Such heating has the following advantages:

- there is no loss of coolant during supply to radiators;

- thanks to the use of small diameter pipes, financial costs are reduced;

- the same temperature of fluid supply to all elements of the system;

- high efficiency of the installation;

- reliability;

- you can set the temperature control on a separate battery;

- saving space due to the absence of bulky structures, which is important for small houses;

- the cost of a double-circuit unit is much lower for the total price of a heating boiler and a boiler.

The main criterion for choosing a double-circuit device is a significant saving in space and material resources.

Construction device

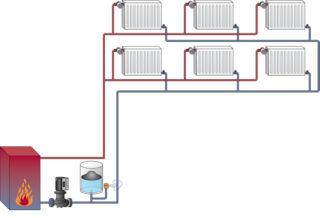

The demanded double-circuit heating system in a private house may have different building schemes, but the main components remain unchanged:

- boiler for heating the coolant;

- an expansion tank for replenishing the amount of water during its heating;

- pumping unit for circulating hot liquid along the circuits;

- radiators, with the help of which heat is efficiently transferred to the heated room;

- controlling elements.

A dual-circuit heating system provides the house with hot water and heat from a single source. Installing a circulating pump significantly increases the efficiency of the utility network.

In the device of a system of two circuits, it is possible to use a single-circuit boiler, if a boiler with indirect heating is connected to the latter.

Varieties of double-circuit heating systems

Since many two-pipe heating systems are used, each of which has its own characteristics, it is worth understanding the basic diagrams.

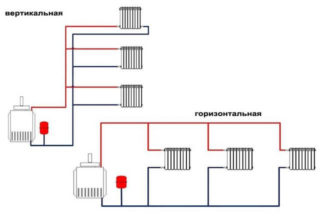

Horizontal and vertical

The type of layout is determined based on the installation method of a two-circuit heating system.

The vertical scheme is better suited for structures with several floors, horizontal - for one-story buildings of a huge area.

In the installation of the first, there are a number of separate risers and batteries. The other has one or two risers, as well as several heating sources located at a single level.

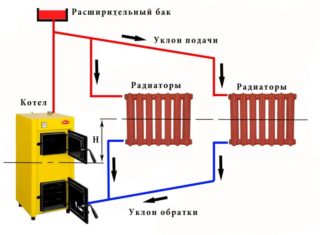

Lower and upper wiring

An important distinctive feature is the location of the tank and the heating unit. In the case of the upper wiring, they are placed under the roof of the structure, with the lower one - in the basement.

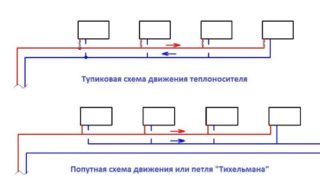

Systems with passing and counter movement of water

In the first, the heated liquid in both circuits has the same direction of movement. In others, cold water flows out from the opposite side, when compared with the direction of movement from the boiler. In such a design, there is an end radiator, where the 2 most distant points are connected.

With natural and forced circulation

The movement of the heat carrier occurs under the influence of the temperature difference in the contours of structures with a natural circulation. In this case, the water heats up slowly, but there is no need to install a pump. In systems with forced circulation, a pump is mounted on one circuit, the operation of which sets the coolant in motion. Thanks to such a popular scheme, heat is evenly distributed throughout the territory of the building.

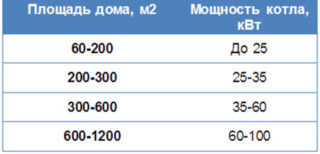

Calculation of boiler power and boiler capacity

With the correct power of the heating unit in the combustion chamber, the temperature will not rise above 90 ° C, which significantly increases the service life of the equipment.

The simplest calculation method:

Q = S × A × k

- Q - thermal power (Watt);

- S - internal area of the structure (m²);

- A - the number of watts from the total power of the heating system per 1m² (as a rule, 100 - 150 watts);

- k - safety factor for a strong cold snap (1.2 or 1.25).

If the total area of the heated room is about 100 m2, the maximum power cannot exceed 38 kW. The boiler usually has two values. The first shows the energy consumption in heating mode, the second shows the power for fast heating of water.

The capacity of the boiler should be calculated based on future consumption: an average of 10 liters for washing dishes, 30 liters for taking a shower, 100 liters for a bath and a large wash.

Preparatory work

The procedure for the troublesome installation of a two-circuit heating system usually begins with complex hydraulic calculations. There is practically no way to do this properly on your own. Therefore, it is recommended to turn to professionals: they are able to take into account all the nuances and peculiarities of the structure in which it is required to install heating equipment. A correctly selected heating scheme for a private house with a gas double-circuit boiler will ensure a more economical use of resources for heating in the future.

A competent calculation will help you choose the optimal structural solution for the construction, the number of component parts that will certainly be required to connect the heating system.

Equipment installation

Installation of a heating circuit system consists of successive stages. Their implementation should be approached responsibly so as not to violate the final design.

- The heating boiler and the upper part of the circuit are installed, the purpose of the latter is to supply the coolant to the radiators.

- The tank is being installed with small taps for removing water, a branch pipe.

- A line with batteries is laid through the rooms.

- If necessary, a pump is cut in to ensure circulation in the return circuit.

It is better to connect radiators that have small taps at the inlet and outlet. This nuance will allow the batteries to function in an autonomous mode, as well as to repair an individual element without shutting down the system installation.

After the connection is completed, the equipment is carefully inspected for the presence of defects and the reliability of the couplings.

Natural gas is considered to be the best fuel, but its use requires certain rules to be followed to avoid causing a hazard.

Modern devices are equipped with automation that controls the heating level and maintains the desired temperature regime.

How high is the efficiency of the installation?

how much heat energy you dissipated inside the house / room, so much is.

and it disappears only into the external environment minus the ventilation / chimney.

I understand the efficiency of some kind of converter, this is an indicator of how much energy the device spends for its intended purpose, and how much goes into heat.

heating right there - everything is warm, or have you already pledged expenses for the management company?