In cold climates, it sometimes happens that during the night the water in the pipes freezes and it is impossible to get it from there for domestic needs. In this case, it is necessary to organize thermal insulation for the water supply pipes. There are several ways, depending on the type and material of the insulation.

- Reasons for insulating water pipes

- Warming methods

- Increasing pressure in the water supply system

- Water pipe heating cable

- Thermal insulation for water pipes

- Materials for pipe insulation

- Rigid insulation

- Rolled insulation

- Segment heaters

- Sprayed heaters

- Do-it-yourself warming process

- Underfloor insulation

- On open air

- In the ground

- Additional frost protection

Reasons for insulating water pipes

All materials are subject to expansion, the degree of which is different for plastic and metal. When ice forms inside, it is capable of breaking both steel and plastic. As a result, there will be no water in the house even during the thaw, since it will all flow out into the crack.

To fix a burst water pipe, the crack must first be found. It does not matter what is the distance from the well to the house - you will have to excavate the entire highway. Then you need to replace the site - buy a piece of pipe from a suitable material, invite a welder to do all the work. After that, bury the pipe back. It is good if the situation does not repeat next year, but while the pipe is open after emergency excavations, it is advisable to insulate it and forget about the incident.

The lower the pipe is in the ground, the less likely it is to freeze. If an accident occurs, then the water supply system is located in the zone of soil freezing. It is imperative to insulate it.

Warming methods

It is not always possible to lay pipes deeply, due to the peculiarities of the soil. For example, groundwater may come too close to the surface of the earth, or the bottom layer is solid rock. Alternative ways to avoid the accident are worth considering.

Increasing pressure in the water supply system

So that water enters the house faster and does not linger in the pipe, you can increase the pressure of the pump located in the well. A check valve is installed after the pump, which prevents the pressure from decreasing after shutdown. In this case, submersible units, in which the pressure is higher, work best.

Water pipe heating cable

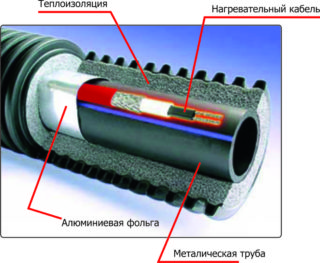

For the winter period, a heating cable is also suitable, which is laid in or on top of a pipe. The power of 10 - 20 W is quite enough so that the liquid inside does not freeze. These are economical systems that can be turned on at low temperatures. It is possible to connect a temperature sensor that will automatically turn on the heating if frost hits at night.

The cable is connected complete with insulation materials or as the only way to heat pipes.

Thermal insulation for water pipes

An inexpensive way is to insulate underground utilities with various insulating materials that retain heat and do not allow cold to pass through. These include:

- Styrofoam;

- expanded polystyrene;

- penoplex;

- stone mineral wool;

- glass wool.

Materials can be solid or sold in rolls. For example, high-density rock wool has the appearance of a pipe that has been cut from both sides for ease of installation.After installing the frame on the pipe, the two halves are fastened with tape.

For underground work, all insulation must be hydrophobic (not absorbent). If the pipes are located above the surface of the ground, such areas must be insulated with a thicker layer.

Materials for pipe insulation

Heaters for water pipes can be selected according to the degree of rigidity, price, moisture resistance and durability. Rigid materials last longer and are not exposed to aggressive environmental influences: they do not absorb water, do not grow moldy, do not lose their shape during temperature extremes.

Rigid insulation

Hard insulation includes:

- Basalt mineral wool is a substance that is obtained by melting volcanic rocks, which, using special equipment, are turned into long fibers and pressed into slabs. This material is not afraid of moisture if it is additionally treated with water-repellent agents. Bacteria do not damage the mineral wool, therefore, its service life reaches 50 years in aggressive conditions. For insulation of pipes, it is produced in the form of a shell, which is fastened with adhesive tape during installation.

- Penoplex or extruded polystyrene foam. The material is expensive, since the service life, as well as the characteristics of thermal conductivity, hygroscopicity, zero vapor permeability, make it possible to once and for all solve the problem of pipe insulation in the ground. Penoplex resists compressive loads well, therefore it is suitable for use in soil where natural shifts and damage to the integrity of the coating and pipes can occur. It is a synthetic material and therefore does not rot. For pipes, it is produced in the form of two halves, between which a water main is laid, but you can also use plates by making a box out of them.

- Polyfoam is a less expensive material, but it meets all the requirements for thermal conductivity and does not absorb moisture. Thermal insulation of a water supply system with polystyrene is possible in two ways - arranging a box or shell along the diameter of the pipe.

When choosing a rigid insulation, it is necessary to take into account where the water supply is located - in the soil or on the surface, in order to choose an ultraviolet-resistant material, for example, stone wool, since foam and foam are destroyed by sunlight.

Rolled insulation

Among the rolled insulation for the water supply pipe, you can use:

- Foil penofol. Foamed polyethylene has good thermal conductivity and vapor permeability characteristics. A feature of the material is that it is laid on pipes on top of another, for example, glass wool.

- Glass wool for pipes should be purchased with a hydrophobic coating so that it does not absorb moisture and does not lose its properties. If the pipes are metal, moisture can lead to rust formation. Masters do not advise to lay only glass wool, you need to wrap it with another layer, which leads to a rise in the cost of the water supply system.

- Stone wool in rolls. Insulated pipes for water supply with this natural material do not form condensation and maintain a constant temperature inside.

- Synthetic rubber - can be used to insulate underground water pipelines for wrapping pipes. The seams are sealed tightly with a blowtorch so that water cannot penetrate inside. Open areas in the sun are not wrapped with this material, as the rubber melts.

Combinations of materials and technologies are possible, for example, electric cable and basalt wool.

Segment heaters

Segmental heaters are produced in a hard and soft form. The hard shells include expanded polystyrene shells, polystyrene foam. For soft - foamed polyethylene, penofol. Basalt cylinders can be of different densities, but it is better to choose denser shells - they absorb less moisture.

Sprayed heaters

You can protect pipes from freezing with polyurethane foam. The method has the following advantages:

- absolutely sealed spraying;

- water-repellent properties;

- not damaged by mold.

The method is quite expensive. The price depends on the thickness of the shell to be created above the pipe surface.

Many people underestimate the technology of spraying heat-insulating paint for insulating a water supply system from a HDPE pipe in the ground. A 2 mm layer of thermal paint is similar to 50 mm glass wool. It also protects metal pipes from rust. It is based on ceramic microparticles.

Do-it-yourself warming process

When insulating a water supply system, it matters where the highway is located: underground, above the surface of the soil, the depth relative to the level of freezing of the soil. This will determine which layer of insulation to calculate. In the northern regions, where the soil freezes over 2.5 m in winter, a double layer of thermal protection is indispensable. You can also combine technologies.

Underfloor insulation

If the pipe runs under the floor, but is located above the ground, the cold will reach it if the frost drops to minus 15 degrees. It is good if the measures for the insulation of the water supply are carried out at the stage of construction or overhaul. If the house is old, the floors will have to be removed.

Any material is suitable for thermal insulation. Better synthetic, so that it does not absorb moisture, for example, foam or expanded polyethylene. Rolled insulation will need to be wrapped in a water-repellent material in addition.

If the pipes under the floor are planned to be poured with concrete, you need dense polystyrene foam or high-density pressed stone wool, treated with a hydrophobic shell-like composition.

On open air

The thickness of the insulation layer for the ground water supply should be greater, since the air freezes more than the ground. If only part of the pipe is exposed to the open air, it is insulated first. Perhaps the lack of water in the house is associated with this particular place.

If the entire line is located outdoors, it is recommended to lay the heating cable along its entire length and additionally insulate it with cotton wool or synthetic materials.

Insulation of the water supply with a cable over the pipe:

- Glue the pipe in a spiral with foil tape.

- Lay the cable on it and rewind it with foil tape.

- Put a shell of any insulation on top of the cable and fix it with adhesive plumbing tape, paying special attention to the joints.

- Connect the cable to an outlet or power supply unit with control according to the instructions.

To save money, a sensor is connected to turn on heating without human intervention.

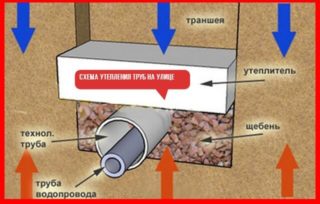

In the ground

Materials with low water absorption are expensive but last long. They do not need additional devices in the form of windings or box arrangement. The more joints, the more likely it is that moisture will still penetrate the insulation. To reduce the risk, it is recommended to lay the layers with an offset and seal the joints with good quality tape.

To wrap the pipes, they need to be dug out. This is a large amount of work, therefore it is most often done during the construction phase of a water supply system. If frosts in the region reach minus 10 degrees, and the highway is laid 50 cm into the ground, most likely you will have to face a lack of water in winter at best.

If you plan ahead for the thermal insulation of your water supply, you don't have to dig deep trenches to lay the pipes. In the northern regions, even a deep location of the water supply system does not save from accidents and rupture of sections of the mainline, therefore, the further north the place of residence is, the more obligatory heat protection is.

Additional frost protection

It is worth paying attention to the additional method of heating the water supply system. It is connected only during the cold season. It is about increasing the pressure in the pipe.This method is used in the country, where no one lives in winter and there is a risk of water freezing in the pipes.

In order to be able to increase the pressure to 3 - 5 atmospheres, it is necessary to have a strong system of water pipes that can withstand the pressure. If they are made of weak material, this will lead to tearing at the joints. A non-return valve is installed, pressure is built up, the system remains in this state for the winter. To make the water supply work again, the excess pressure is released. You can use it periodically when severe frosts are outlined.

If this method is not suitable due to the poor condition of the water supply system, you can use another method, which is more costly, but without the risk of damaging the pipes. This is the constant circulation of fluid in the system. In order not to waste water and not drain it into a septic tank, which will quickly overflow, you can equip a return pipe to drain the liquid into the well. In this case, the pump will periodically turn on and off. This can be more expensive, so it's worth calculating the approximate costs.