Thermal insulation of engineering systems is necessary to solve a whole range of problems. It allows you to reduce heat losses on the way to the consumer, protect the contents from the harmful effects of the environment, reduce energy costs and extend the service life. Technical insulation for K Flex pipes is one of the most advanced and effective thermal protection options.

Characteristics of thermal insulation Kaflex

Thermal insulation K Flex is made of foamed synthetic rubber with various additives, due to which it has high operational and thermal properties.

Technical characteristics of K Flex pipe insulation:

- Low thermal conductivity due to high porosity combined with small cells.

- Low vapor permeability. Insulation for pipes K Flex has a porous structure with closed cells, which provides high resistance to dripping moisture and vaporization. Throughout the entire operational life, the structure does not accumulate moisture in itself, the heat-shielding properties do not undergo transformations.

- High manufacturability of the installation.

- A wide range of operating temperatures, the indicators of which fluctuate between -198 - +150 degrees.

- Durability. The manufacturer assures that the service life of the material during heat aging will be at least 25 years.

The technical characteristics of almost all modifications are similar, but there are distinctive features that you need to familiarize yourself with before buying.

Types of insulation Kaflex

Thermal insulation for K Flex pipes is divided into several varieties, each of which differs in character and stones and field of application.

Thermal insulation K Flex ST

This modification is capable of operating smoothly at temperatures ranging from - 200 to +105 degrees Celsius. Thermal conductivity at -20 degrees is 0.034, and at +20 - 0.038.

The material is actively used in the following industries:

- refrigeration equipment;

- petrochemical facilities;

- ventilation and air conditioning systems;

- industrial pipelines;

- heating and water supply systems.

The advantages of K Flex ST material are neutral odor, environmental friendliness and biological resistance. Fire safety - G1.

K Flex Solar HT

It is used at operating temperatures up to +150 degrees. It is actively used in the following industries:

- low pressure steam pipelines, in which the temperature regime does not exceed +150 degrees;

- solar systems;

- pipelines and industrial equipment;

- high temperature insulation.

The thermal conductivity coefficient at a temperature of +20 degrees is 0.04, and at +60 - 0.045. Belongs to the fire safety class - G1.

The insulating sheet is odor-neutral.

K-Flex ECO

It is actively used in the following areas:

- Metro stations;

- pharmaceutical production;

- railway transport and airports;

- offshore platforms;

- computer centers;

- construction of ships and ships;

- food production;

- hospitals;

- clean rooms;

- preschool institutions, schools.

The material is characterized by the following thermal conductivity indicators: at -20 - 0.036, and at +20 - 0.04. Fire safety belongs to the class G2, RP1, T2. Designed to operate in a temperature range from -70 to +150 degrees.

Insulation ECO has neutral acidity, neutral odor, green color.

Insulation for pipes Kaflex IGO

The material is used in the following industries:

- for heat insulation of welded seams;

- in the construction of thermal insulation;

- for industrial pipelines that are laid above- and underground.

Operating temperature range from -60 to +105 degrees. Thermal conductivity at 0 degrees - 0.044, +20 - 0.046. The color is black, the smell is neutral. Fire safety class - G2.

Insulation K-Flex for ST / SK pipes

This modification is a pre-cut roll insulation, on the surface of which a special glue is contained. Thanks to the adhesive mass, the material becomes tubular. The technology ensures ease of use and high speed of installation.

It is used in the following cases:

- cooling lines;

- laying of pipelines;

- ventilation and air conditioning systems.

It has a black color, the material is characterized by a neutral acidity index. The thermal conductivity coefficient is at -20 degrees - 0.034 and at +20 - 0.038.

A wide variety of thermal insulation materials allows you to use the insulation as efficiently as possible in any conditions. It is important to consider all requirements before purchasing.

Advantages and disadvantages

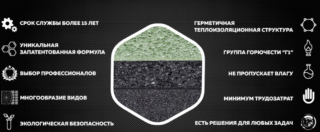

The manufacturer of K Flex products is very popular due to its many advantages. All modifications are characterized by increased thermal insulation properties, as well as:

- environmental Safety;

- long operational life - the manufacturer assures that the minimum service life is 25 years, in fact, users note that it is more;

- high assembly adaptability - when installing thermal insulation, there is no need to additionally use vapor barrier layers, fasteners are not needed;

- increased resistance to temperature fluctuations - the operating temperature range ranges from -195 to +150 degrees;

- hydrophobicity;

- protection against corrosion;

- low vapor permeability and thermal conductivity;

- resistance to aggressive environmental factors.

Another important fact is that all materials produced by the company do not emit toxic and toxic substances into the environment. They all have a neutral odor.

Thanks to a wide variety of building materials, it is possible to solve a wide variety of tasks. These products with rotary technical systems are especially in demand, since they are characterized by increased tensile strength and high elasticity.

Of the shortcomings, only the high cost of the Italian manufacturer's products can be distinguished.

Installation methods

The installation process begins with a uniform application of a thin layer of adhesive to the pipe surface and the inside of the heat insulator. For the glue to penetrate deeply into the layers of the material, you need to wait about 2-3 minutes. If self-adhesive modifications are used, this step is skipped. Insulation must be laid on the pipe in such a way that the seam runs along its lower part. At the end, the surface to be pasted must be smoothed out with a little effort.